Repair

28 309574C

Motor Control Board

2. Relieve pressure, page 8.

3. Refer to electrical diagrams. Motor control board is

on right side inside cabinet.

4. Put on static conductive wrist strap.

5. Disconnect all cables and connectors from board.

6. Remove nuts (42) and take entire motor control

assembly to workbench.

7. Remove screws and take board off heatsink.

9. Install new board in reverse order. Apply thermal

heatsink compound to mating surfaces of board and

heatsink.

Motor control board has one red LED (D11 for

245980, D7 for 245981). Power must be on to

check. See F

IG

. 7 for location. Function is:

Startup: one blink for 60 Hz, two blinks for 50 Hz.

Motor running: LED on.

Motor not running: LED off.

Diagnostic code (motor not running): LED blinks

diagnostic code (for example, E21=21 blinks).

CAUTION

Before handling board, put on a static conductive wrist

strap to protect against static discharge which can

damage board. Follow instructions provided with wrist

strap.

1. Turn main power OFF . Disconnect power

supply.

WARNING

Read warnings, page 5. Wait 5 min for stored voltage

to discharge (E-30 and E-XP2 models only).

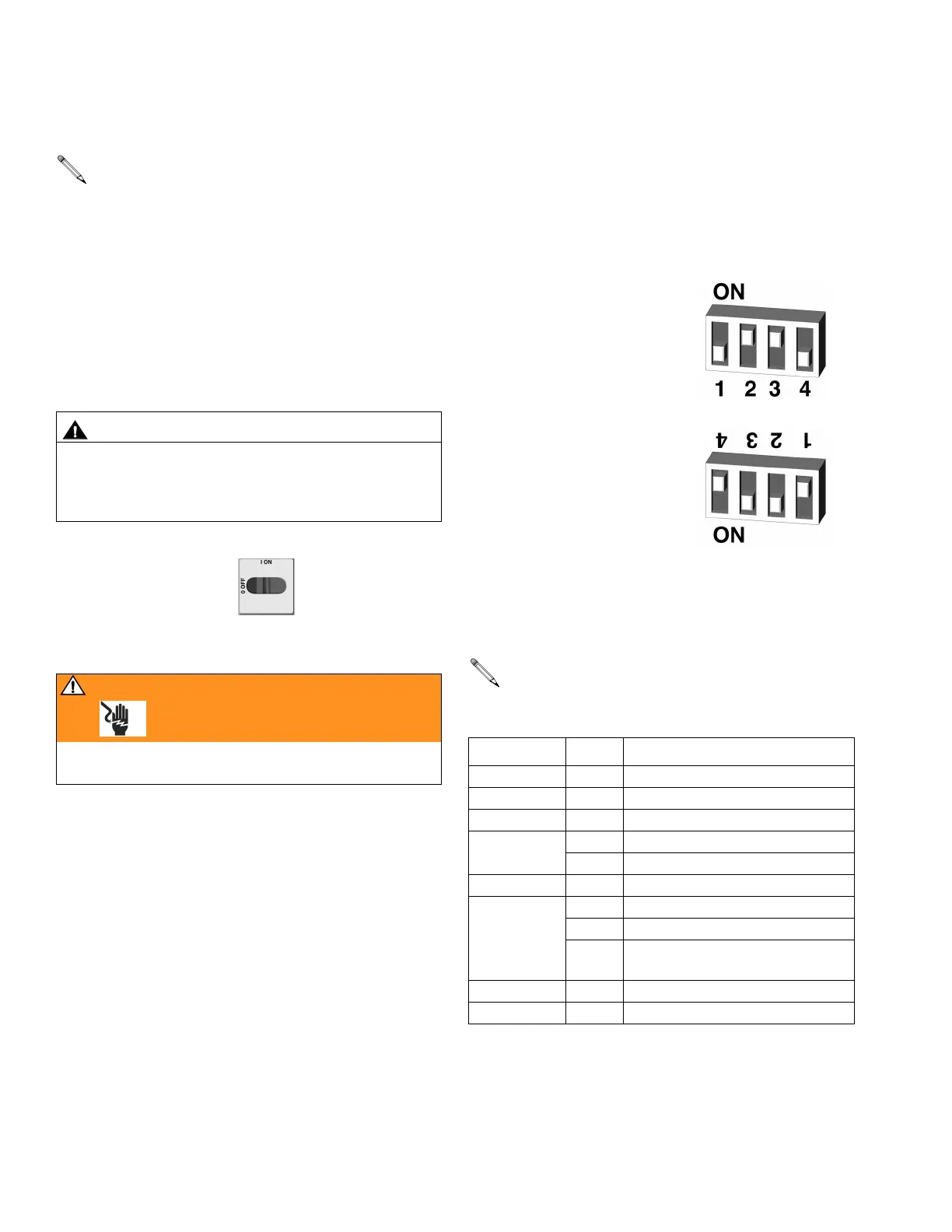

8. Set DIP switch (SW2) on new board. See below for

factory settings. See F

IG

. 7 for location on board.

• Switches 1 and 4: not used, leave OFF.

• Switch 2: ON for Models E-20 and E-30, OFF for

Models E-XP1 and E-XP2.

• Switch 3: ON for pressure imbalance alarm,

OFF for pressure imbalance warning.

Order Part No. 110009 Thermal Compound.

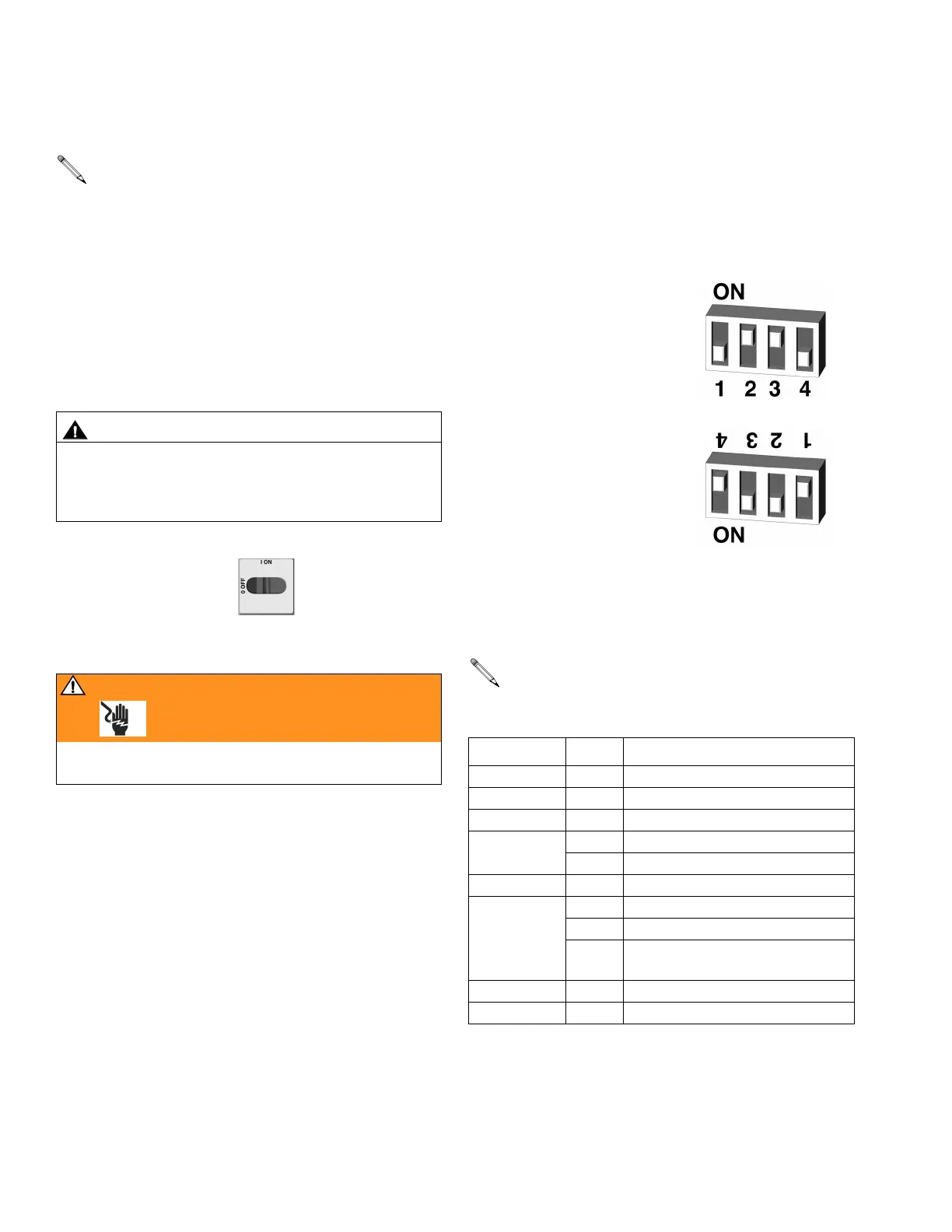

Table 2: Motor Control Board Connectors

Connector Pin Description

J1 n/a Main motor power

J3 n/a Transducer A

J4 n/a Motor output

J7 1, 2 Motor thermal overload signal

3 Brush wear signal

J8 n/a Transducer B

J10 1-4 Not used

5, 6 Cycle switch signal

7-10 Jumper 15C866 (available in

repair kit 246961)

J12 n/a Data reporting

J13 n/a To display board

TI3178a

TI3178a-1

Models E-20 and E-XP1:

Switch 2 ON (Model E-20);

Switch 3 ON (pressure im-

balance alarm).

Models E-30 and E-XP2:

Switch 2 ON (Model E-30);

Switch 3 ON (pressure im-

balance alarm).

Loading...

Loading...