INSTALLATION INSTRUCTIONS Gas Furnace: WFAR

440 01 7104 02 33

Specifications subject to change without notice.

2. Route listed power cord through 7/8--in. (22 mm)

diameter hole in casing and J--Box bracket.

3. Secure power cord to J--Box bracket with a strain relief

bushing or a connector approved for the type of cord

used.

4. Pull furnace power wires through 1/2--in. (12 mm)

diameter hole in J--Box. If necessary, loosen power wires

from strain—relief wire--tie on furnace wiring harness.

5. Connect field ground wire and factory ground wire to

green ground screw on J--Box mounting bracket as

shown in Figure 34.

6. Connect power cord power and neutral leads to furnace

power leads as shown in Figure 37.

7. Attach furnace J--Box cover to mounting bracket with

screws supplied in loose parts bag. Do not pinch wires

between cover and bracket. (See Figure 34).

BX Cable Installation in Furnace J--Box

1. Install J--Box mounting bracket to inside of furnace

casing. See Figure 34.

2. Route BX connector through 7/8--in. (22 mm) diameter

hole in casing and J--Box bracket.

3. Secure BX cable to J--Box bracket with connectors

approved for the type of cable used.

4. Connect field ground wire and factory ground wire to

green ground screw on J--Box mounting bracket as

shown in Figure 34.

5. Connect field power and neutral leads to furnace power

leads. as shown in Figure 37.

6. Attach furnace J--Box cover to mounting bracket with

screws supplied in loose parts bag. Do not pinch wires

between cover and bracket.

! WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, personal injury, death, or property damage.

Do no drill into blower shelf of furnace to route control wiring.

Route any control or accessory wiring to the blower

compartment through external knockouts on the casing.

24--V Wiring

Make field 24--v connections at the 24--v terminal strip. (See

Figure 38.) Use only AWG No. 18, color--coded, copper

thermostat wire.

NOTE: Use AWG No. 18 color-coded copper thermostat wire

for lengths up to 100 ft. (30.5 M). For wire lengths over 100 ft.,

useAWGNo.16wire.

The 24--v circuit contains an automotive--type, 3--amp. fuse

located on the control. Any direct shorts during installation,

service, or maintenance could cause this fuse to blow. If fuse

replacement is required, use ONLY a 3--amp. fuse of identical

size. See Figure 38.

Accessories (See Figure 36 and Figure 38.)

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used)

using 1/4--in. female quick connect terminals to the two

male 1/4--in. quick--connect terminals on the control

board marked EAC--1 and EAC--2. The terminals are

rated for 115VAC, 1.0 amps maximum and are energized

during blower motor operation.

2. Humidifier (HUM)

The HUM terminal is a 24 VAC output, energized when

the LPS closes during a call for heat.

Connect an accessory 24 VAC, 0.5 amp. maximum

humidifier (if used) to the ¼--in. male quick--connect HUM

terminal and COM--24V screw terminal on the control

board thermostat strip. (See Figure 38.)

NOTE: If the humidifier has its own 24 VAC power supply, an

isolation relay may be required. Connect the 24 VAC coil of the

isolation relay to the HUM and COM/24V screw terminal on the

control board thermostat strip. (See Figure 36.)

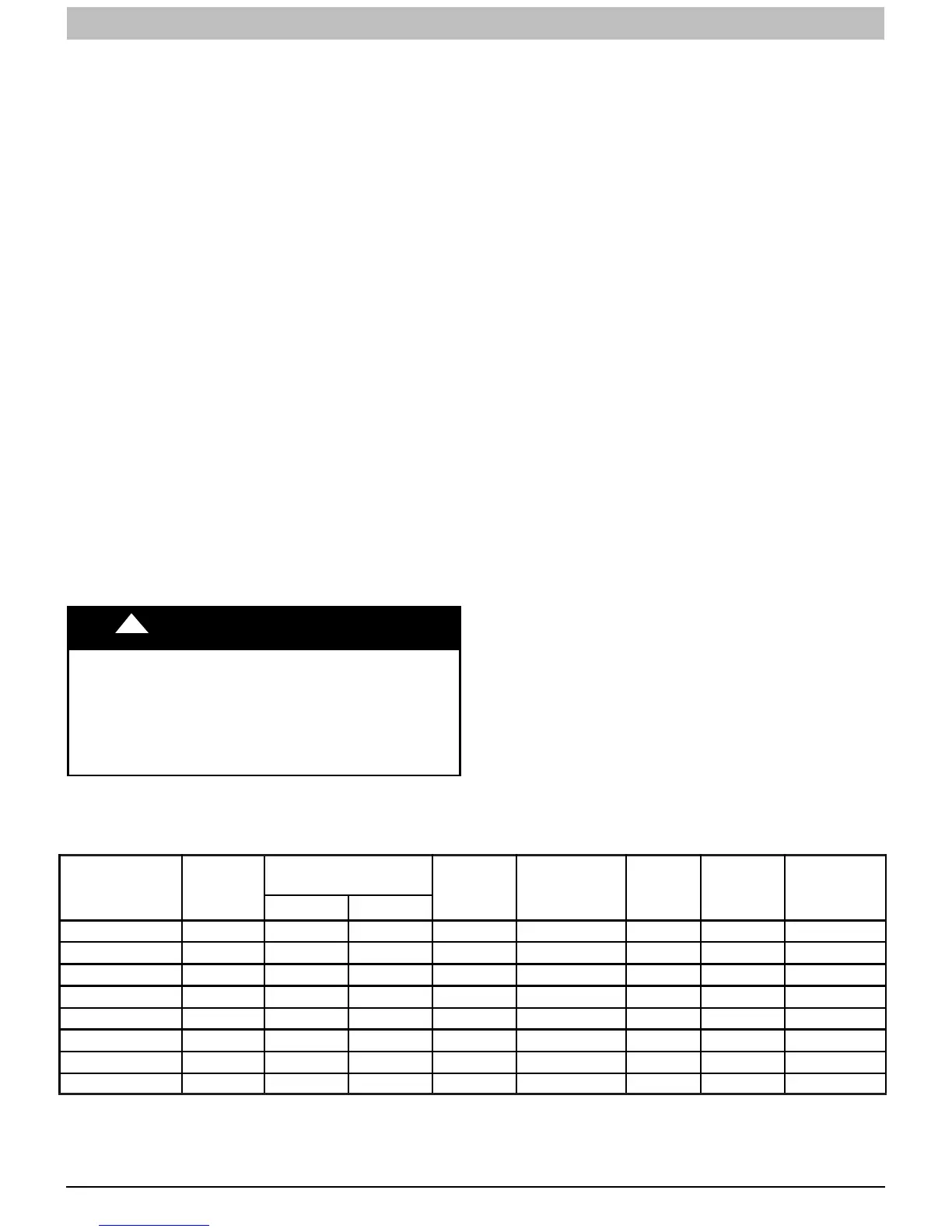

Alternate Power Supplies

This furnace is designed to operate on utility generated power

which has a smooth sinusoidal waveform. If the furnace is to

be operated on a generator or other alternate power supply, the

alternate power supply must produce a smooth sinusoidal

waveform for compatibility with the furnace electronics. The

alternate power supply must generate the same voltage,

phase, and frequency (Hz) as shown in Table 10 or the furnace

rating plate.

Power from an alternate power supply that is non-sinusoidal

may damage the furnace electronics or cause erratic operation.

Contact the alternate power supply manufacturer for

specifications and details.

Table 10 – Electrical Data

UNIT SIZE

VOLTS--

HERTZ--

PHASE

OPERATING VOLTAGE

RANGE*

MAXIMUM

UNIT

AMPS

UNIT

AMPACITY#

MINIMUM

WIRE

SIZE

AWG

MAXIMUM

WIRE

LENGTH

FT (M)}

MAXIMUM

FUSE OR

CKT BKR

AMPS{

Maximum* Minimum*

040A030C 115--60--1 127 104 5.2 7.5 14 49 (14.9) 15

060B048C 115--60--1 127 104 8.6 11.7 14 31 (9.4) 15

080B048B 115--60--1 127 104 8.1 11.1 14 33 (10.1) 15

080B048C 115--60--1 127 104 8.1 11.1 14 33 (10.1) 15

080C060C 115--60--1 127 104 8.6 11.7 14 31 (9.4) 15

100C048C 115--60--1 127 104 7.3 10.1 14 36(11.0) 15

100C060C 115--60--1 127 104 11.9 15.8 12 36(11.0) 20

120D060C 115--60--1 127 104 11.9 15.8 12 36(11.0) 20

* Permissible limits of the voltage range at which the unit operates satisfactorily.

# Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full load

amps.

{Time--delay type is recommended.

}Length shown is as measured one way along wire path between furnace and service panel for maximum 2 percent voltage drop.

Loading...

Loading...