INSTALLATION INSTRUCTIONS Gas Furnace: WFAR

40 440 01 7104 02

Specifications subject to change without notice.

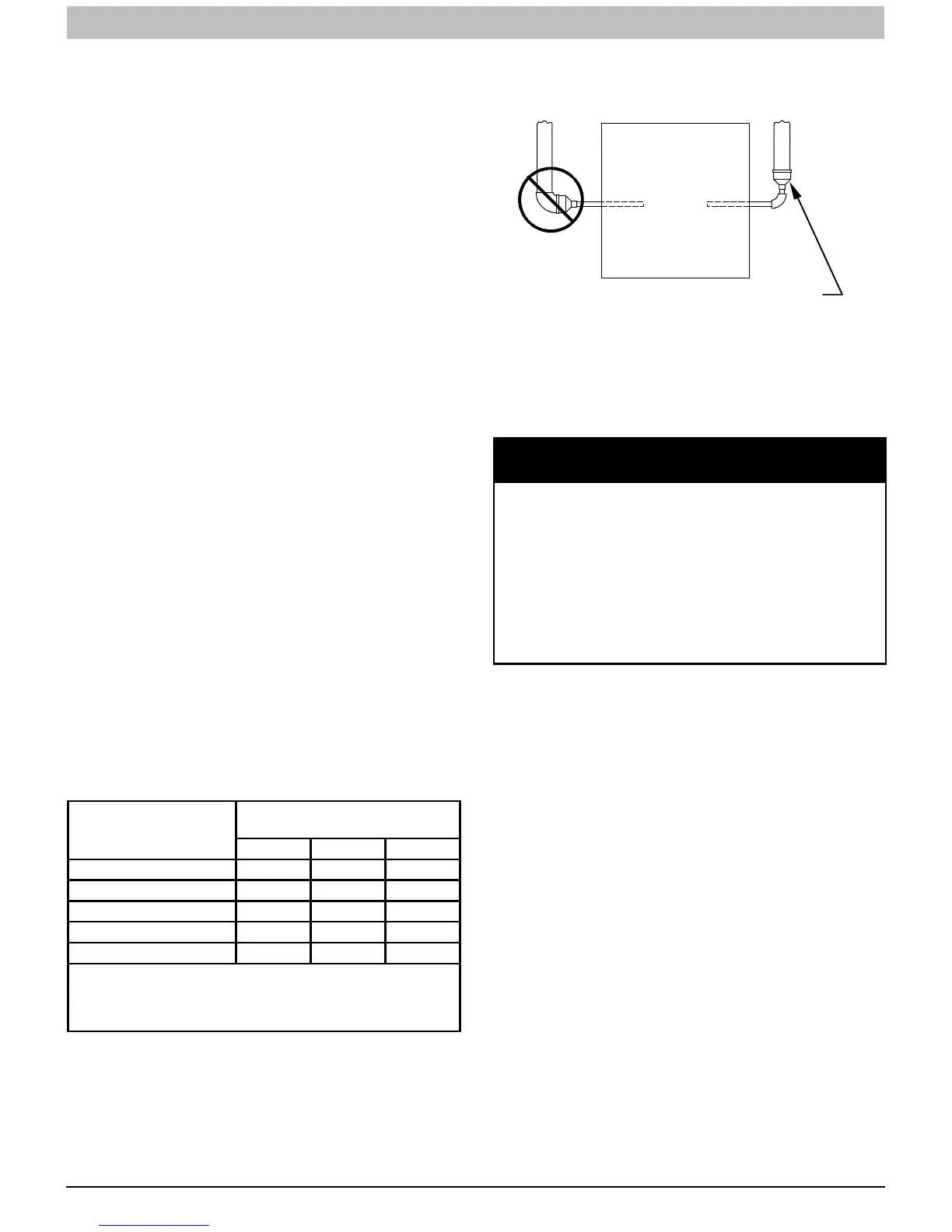

clearances required by National code authorities. Allowable

vent terminations are shown in Figure 54.

A combustion inlet air pipe to the outdoors is not required for a

Non--Direct Vent System. A 12--in. long section of pipe with a

tight radius 2--in. (51 mm) 90 degree elbow is required to be

attached to the furnace. See Figure 55. This short inlet air pipe

helps to ensure inlet air pipe away from occupants. An extra

elbow and/or five fee (1.5 M) of pipe may be used to

accomplish the sound attenuation function.

Termination Requirements for the

Provinces of Alberta and Saskatchewan

The Provinces of Alberta and Saskatchewan require a

minimum unobstructed distance of 4 ft. (1.2 M) from the

foundation to the property line of the adjacent lot for vent

termination of any appliance with an input over 35,000 btuh. If

there is less than 4 ft. (1.2 M) of unobstructed distance to the

property line of the adjacent lot, no type of vent termination is

permitted for appliances with inputs greater than 35,000 btuh.

There are no additional restrictions on unobstructed distances

greater than 8 ft. (2.4 M). All single, two-pipe and concentric

vents may be used, providing all other Code and

manufacturer’s requirements in these instructions are adhered

to. Refer to the appropriate Vent Termination section above for

locating the vent termination

If the unobstructed distance from the foundation to the property

line of the adjacent lot is no less than 4 ft. (1.2 M) and no

greater than 8 ft. (2.4 M), it will be necessary to re-direct the

flue gas plume. In this situation, a concentric vent kit cannot be

used. A 2-pipe termination (or single pipe termination when

permitted) that re-directs the flue gas away by use of an elbow

or tee, certified to ULC S636 from the adjacent property line

must be used. See Figure 55.

The concentric vent kit currently cannot be modified to attach

an elbow to the vent portion of the rain cap. A tee attached to

the rain cap could potentially direct the flue gas plume toward

the intake air stream and contaminate the incoming combustion

air for the furnace.

Refer to Figure 55 for terminations approved for use in Alberta

and Saskatchewan.

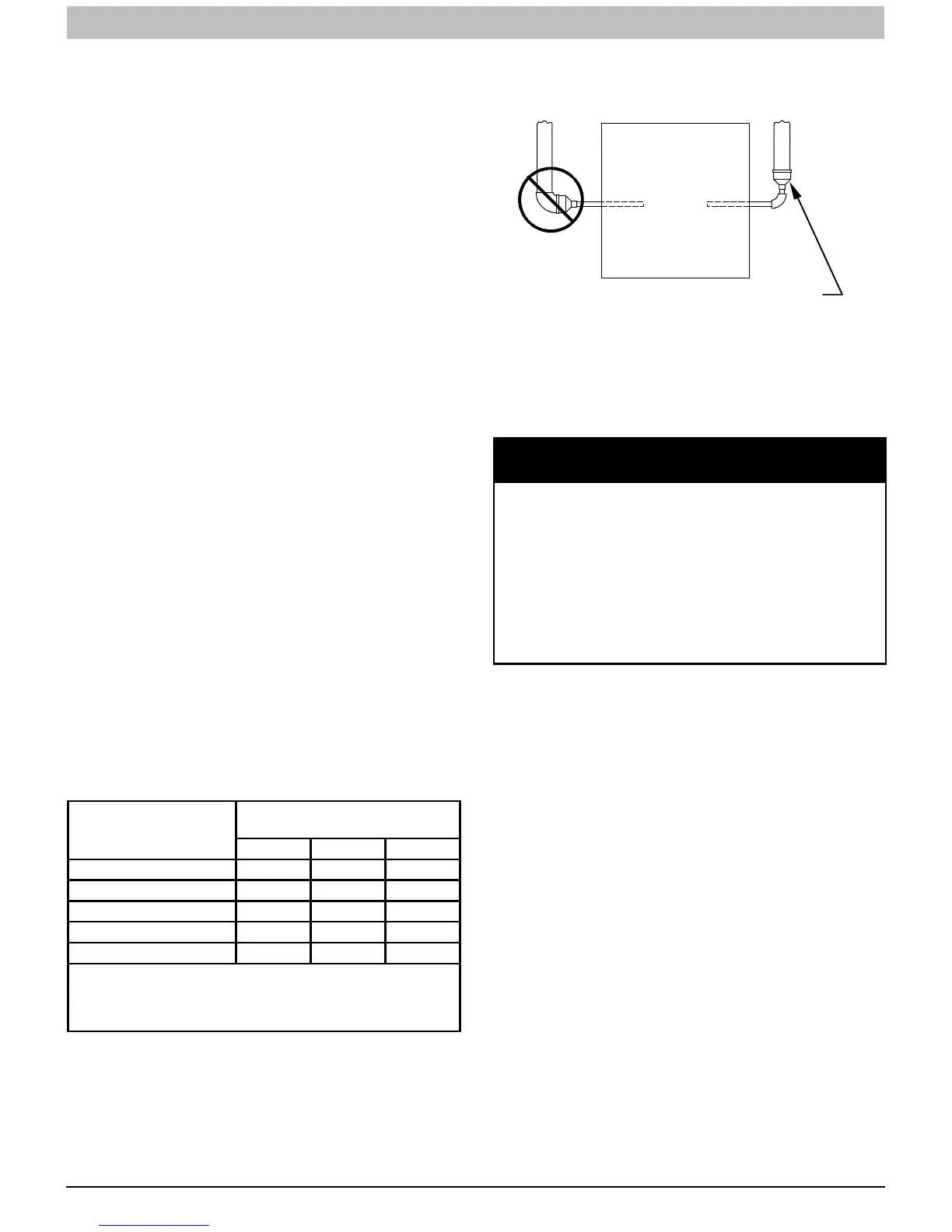

Size the Vent and Combustion Air

Pipes

General

Vent or Combustion Air

Pipe Diameters

Approved 2--pipe

termination fittings

2--in. 3--in. 4--in.

1 1/2--in. X N/A N/A

2--in. X N/A N/A

2 1/2--in. N/A X N/A

3--in. N/A X N/A

4--in. N/A X X

Note: Optional accessory 2--pipe termination brackets are

sized for 2--in. and 3--in. Pipe. If a termination bracket is re-

quired for a 4--in. termination, field fabricate the necessary

brackets and clamps.

Furnace combustion air and vent pipe connections are sized

for 2-in. (50 mm ND) PVC/ABS DWV pipe. The combustion air

and vent pipe connections also accommodate 60mm

polypropylene venting systems with outside diameters of

approximately 60 mm (2--3/8 inches). Any pipe diameter

change should be made outside furnace casing in vertical pipe.

Any change in diameter to the pipe must be made as close to

the furnace as reasonably possible. See Figure 40.

The Maximum Vent Length for the vent and combustion air pipe

(when used) is determined from the Maximum Equivalent Vent

Length in Table 14, minus the number of fittings multiplied by

the deduction for each type of fitting used from Table 15.

A93034

FURNACE

NOT IN

HORIZONTAL

SECTION

PIPE DIAMENTER

TRANSITION IN

SECTION

Figure 40 -- Combustion--Air and Vent Pipe

Diameter Transition Location and Elbow

Configuration

NOTICE

OPTIONAL CONFIGURATION FOR COMBUSTION

AIR INLET PIPE

In applications where there is a risk of excessive mois-

ture entering the combustion air inlet pipe, a moisture

trap may be added to the inlet pipe to help prevent

moisture from entering the furnace from the combus-

tion air inlet pipe. See Figure 57.

When sizing venting systems, the equivalent length of

the optional moisture trap (15 feet/5 M) must be taken

into account.

Combustion Air Inlet Moisture Trap

To prevent moisture from trickling into the furnace vestibule, a

trap can be installed in the intake air pipe near the furnace.

Connecting a drain line to the trap is recommended as trace

amounts of moisture will evaporate into the intake air stream. If

the combustion air inlet is located near a moisture exhaust

duct, or there are other concerns of excessive moisture being

drawn into the combustion air inlet, it is encouraged to connect

adrainlinetothetrap.

The trap can be constructed from a running tee of the same

diameter of the intake air pipe with EITHER a removable cap

attached to a 6-inch long pipe connected to the tee or the

External vent Trap Kit to help prevent contaminants from

entering the furnace. See

Figure 57.

The External Vent Trap Kit accessory may be used as a trap for

the combustion air inlet pipe if a large amount of moisture must

be removed. The drain line may be connected to the same

drain as the furnace condensate and the evaporator coil

condensate line ONLY if the inlet air trap drain and the

evaporator coil drain empty into an open segment of pipe

above the drain, See

Figure 13. When using the External Vent

Trap Kit, refer to those instructions for proper drain

connections.

The tee may also be connected to the intake air pipe on the

side of the casing. See

Figure 57.

In any configuration, it will be necessary to add the equivalent

length of the tee (15 feet/5 M) to the Total Equivalent Vent

Length of the venting system.

Loading...

Loading...