13

MAINTENANCE SAFETY

nn

nn

n

Always perform maintenance with the machine

parked on a hard level surface; with the engine

stopped and the PTO disengaged; with the park

brake set; and with the key removed from the

ignition.

nn

nn

n Always remove the grounded (-) clamp from

the battery when performing maintenance on the

engine, clutch, or any other electrical system.

nn

nn

n Never work under the machine without jack

stands or other equivalent safety blocks. Do

NOT rely solely on mechanical or hydraulic

jacks or lifts for support. Always use ad-

equate wheel chocks on tires remaining on

the ground.

nn

nn

n Hydraulic hoses can fail due to physical dam-

age, kinks, age, and exposure. Check hoses

regularly. Replace damaged hoses.

nn

nn

n Escaping fluid under pressure can penetrate

the skin causing serious injury. Avoid the

hazard by relieving pressure before discon-

necting hydraulic or other lines. Tighten all

connections before applying pressure. If an

accident occurs, see a doctor immediately.

Any fluid injected into the skin must be surgi-

cally removed within a few hours or gangrene

may result.

nn

nn

n Search for leaks with a piece of cardboard.

Protect hands and body from high pressure

fluids.

nn

nn

n If it is necessary to run an engine in an en-

closed area, remove the exhaust fumes from

the area with an exhaust pipe extension. If an

exhaust pipe extension is not available, work

near open doors and get outside air into the

area.

nn

nn

n Waste products such as used oil, fuel, cool-

ant, and batteries can harm the environment

and people. Dispose of waste products

properly.

nn

nn

n Never attempt to disconnect or alter any part

of the safety interlock systems.

nn

nn

n Keep engine free of grass, leaves, or excess

grease to reduce fire hazard and minimize en-

gine overheating.

nn

nn

n Do not change engine governor settings.

nn

nn

n Keep tractor and attachments in good oper-

ating condition and all safety devices in place.

nn

nn

n Periodically tighten all bolts, nuts and screws.

Check that all cotter pins are properly in-

stalled to ensure equipment is in a safe

condition.

nn

nn

n

Check brake operation frequently. Adjust

and service as required.

STORING SAFELY

nn

nn

n Never store equipment with gasoline in the

tank inside a building where fumes may reach

an open flame, spark or pilot light as on a fur-

nace, water heater, clothes dryer, or other

gas appliance. Allow engine to cool before

storing in an enclosure.

nn

nn

n If engine is to be unused for 30 days or more,

add a fuel stabilizer to the fuel system. Fuel

stabilizer (such as STA

.

BIL

®

) is an accept-

able additive in minimizing the formation of

fuel gum deposits during storage. Add stabi-

lizer to gasoline in fuel tank or storage

container. Always follow mix ratio found on

stabilizer container. Run engine at least 10

minutes after adding stabilizer to allow it to

reach the carburetor.

nn

nn

n If draining fuel tank, drain fuel into an ap-

proved container outdoors and away from

open flame.

nn

nn

n Always provide adequate ventilation when

running engine indoors. Exhaust gases contain

carbon monoxide, an odorless and deadly

poison.

nn

nn

n Remove attachments from tractor. Remove

all accumulated debris from attachments and

tractor.

nn

nn

n Sand areas where paint is chipped and re-

paint to prevent rust. Lubricate all locations

to prevent moisture damage during storage.

44

ItemItem

ItemItem

Item

OrderOrder

OrderOrder

Order

DescriptionDescription

DescriptionDescription

Description

No.No.

No.No.

No.

No.No.

No.No.

No.

ItemItem

ItemItem

Item

OrderOrder

OrderOrder

Order

DescriptionDescription

DescriptionDescription

Description

No.No.

No.No.

No.

No.No.

No.No.

No.

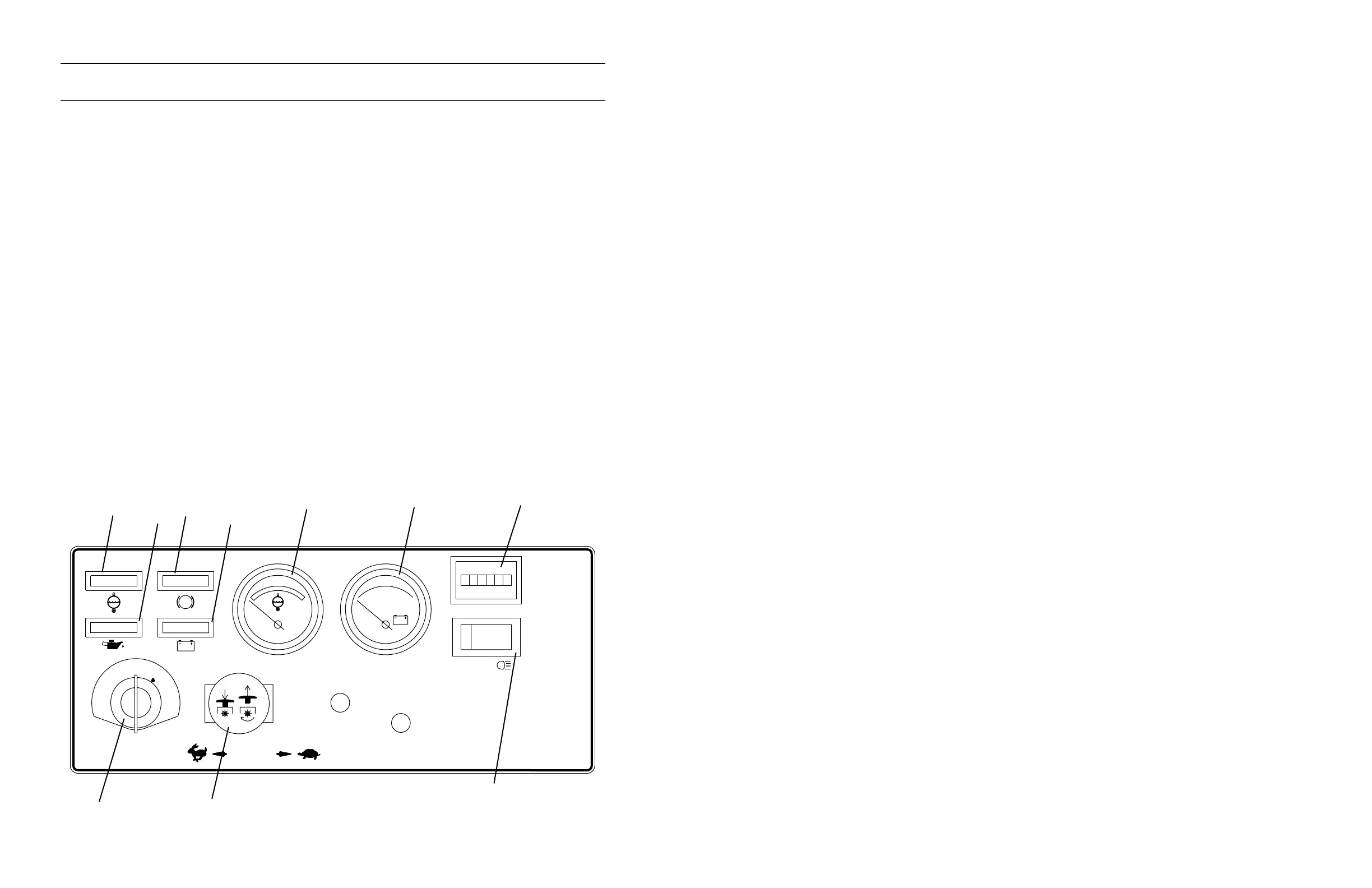

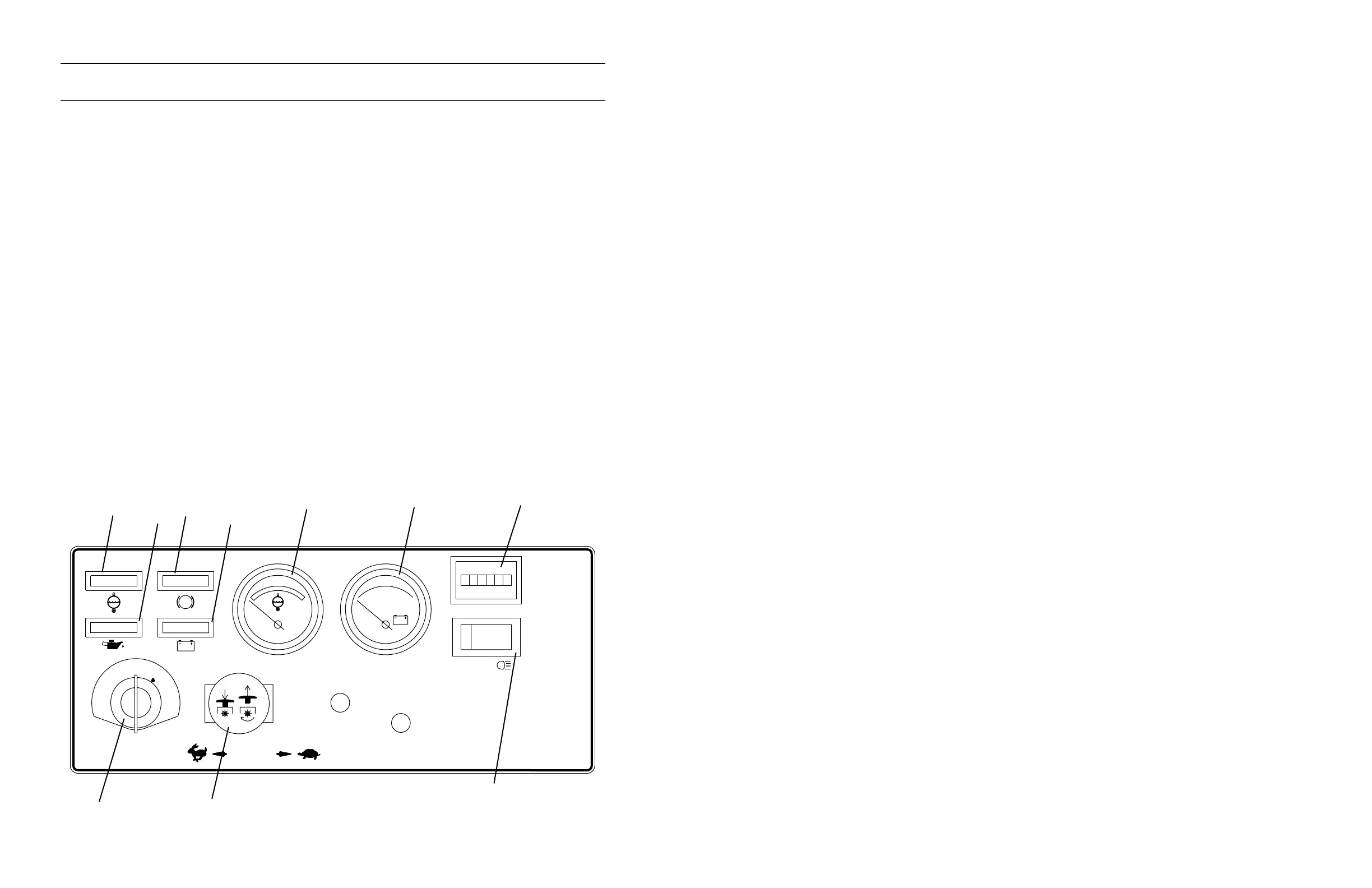

WIRING DIAGRAM

604974 Wiring Assembly - 721D

161131 Decal - Console

1 141160 Coolant Temperature Gauge

2 141200 Voltmeter Gauge

3 182327 Oil Indicator Light

4 182328 Temperature Indicator Light

5 182325 Battery Indicator Light

6 182326 Brake Indicator Light

7 184179 Light Switch

8 183925 Clutch Switch

9 183827 Ignition Switch

10 183860 Safety Switch - Rt. Steering

720160 Rt. Steering Switch Mount

11 183860 Safety Switch - Lt. Steering

720161 Lt. Steering Switch Mount

12 182253 Worklight Assembly

(includes item 13)

13 182005 Light Bulb

14 182251 Bezel

15 603350 Fuel Solenoid

16 184220 Module - Switch Interlock

17 181735 Fuse Holder

181470 Fuse 30 Amp Auto

18 141222 Temperature Sender

19 183871 Seat Safety Switch

20 184272 Relay

21 181722 Fuse Block

184458 1 Wire Clip

184460 2 Wire Clip

184472 Double Clip

22 181470 Fuse 30 Amp Auto

181465 Fuse 15 Amp Auto

181462 Fuse 10 Amp Auto

181460 Fuse 7.5 Amp Auto

23 141551 Hour Meter

24 183894 Brake Switch

25 185530 Voltage Regulator

26 180130 Battery - 12V

243309 Bolt

644163 Battery Box

644478 Battery Box Lid

754135 Battery Hold Down Bracket

27 180313 Battery Cable

425219 Battery Terminal Boot

28 180276 Ground Cable

29 423690 Spacer - PC Board Support

93047 / 01-06055

Rev. 3-07

VOLTS

P

9

8

23

7

1

2

93047

THROTTLE

FAST SLOW

OIL

BRAKE

BATTERY

TEMP

ENGAGE

OUT TO

PTO CLUTCH

PULL

HOURS

LIGHTS

OFFON

6

5

S

t

a

r

t

e

r

S

w

i

t

c

h

S

t

a

r

t

C

o

n

t

a

c

t

P

r

e

h

e

a

t

4

3

Loading...

Loading...