22

LUBRICATION AND MAINTENANCE

CAPACITIES

Fuel Tank .................................................. 16.3 l

Drive System ............................................. 2.37 l

Drive System Fluid Change

approx. ................................. 1.89 l

TIRE AIR PRESSURE

Drive Tires

Standard 22 x 11 x 10 ............... 55 kPa (8 psi)

Optional 22 x 10 x 10 ................ 55 kPa (8 psi)

(refer to decal on wheel for correct tire air pres-

sure)

Rear Tires ............... 83 to 103 kPa (12 to 15 psi)

DRIVE SYSTEM

Fluid Change .................................... 1000 hours

Filter Change .................................... 1000 hours

CRANKCASE OIL AND AIR FILTER

Refer to the “Engine Manual” for the time table

for changing or service.

COOLING SYSTEM

Remove and clean radiator screen regularly. A

dirty screen will cause the engine to overheat.

Do not use high pressure water or steam to

clean the engine or drive compartment.

Water and cleaning detergent may

damage electrical components and

terminals, possibly leading to component

and safety circuit failure.

Use a vacuum cleaner or air blower to remove

foreign material from the engine and drive com-

partment.

Check engine coolant when the engine is cool. If

coolant is required, fill expansion tank to proper

level through radiator. A solution of 50% anti-

freeze and 50% water must be used (freezing

point about –34° F [–36° C]). Do not use 100%

antifreeze or severe damage will occur.

Always wear safety glasses and ear

protection when performing any

maintenance function that could

cause injury to eyes or ears.

Read all safety information on pages 6 through 13.

Lower attachment to ground, shut off

tractor engine, remove key and wires

to fuel solenoid before performing any

maintenance.

LUBRICATION

Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

The chart gives the frequency of lubrication in

operating hours based on normal operating con-

ditions. Severe or unusual conditions may require

more frequent lubrication.

Use an SAE multipurpose type grease for all lo-

cations shown. Be sure to clean fitting thoroughly

before using grease gun.

For Drive System, use Grasshopper Fluid, part no.

345050 for 1 quart (.94 l) container or part no.

345055 for 1 gallon (3.76 l) container.

Lubricate Every Lubricate Every

8 Hours of Usage 80 Hours of Usage

Rear Wheel Bearings Clutch Power Shaft

(two fitting) (two fittings)

Drive Shaft

(one fitting)

35

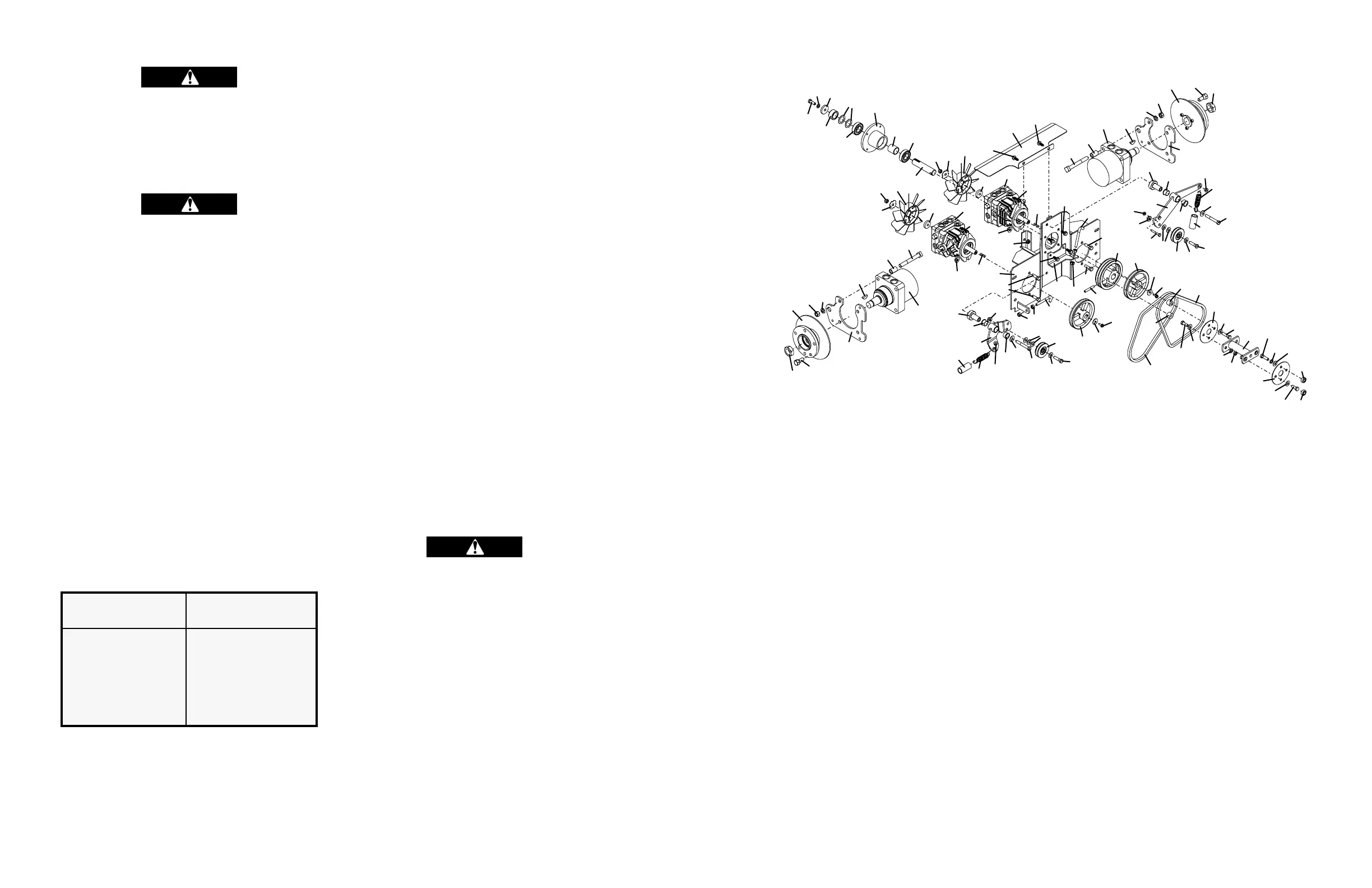

DRIVE ASSEMBLY

05086A

18

17

51

50

49

15

13

14

15

16

9

11

10

11

10

9

30

30

52

8

7

44

12

53

57

1 5

58

54

55

40

39

45

46

2

3

4

30

8

6

44

44

31

12

44

53

57

1

5

58

54

55

2

3

4

47

32

19

32

20

23

56

30

21

32

24

26

25

27

26

33

35

25

33

36

28

17

34

35

17

33

29

29

35

33

27

34

48

24

56

22

47

34

33

43

33

36

42

41

39

44

40

39

37

45

46

59

33

60

44

61

38

43

33

36

39

59

41

42

RIGHT

SIDE

LEFT

SIDE

Rev. 03-07

Loading...

Loading...