19

weights when not required.

nn

nn

n

Use extra care with grass catchers or other

attachments. These can change the stabil-

ity of the machine. Do not use grass

catcher on steep slopes.

nn

nn

n Do not operate without ROPS deployed.

nn

nn

n If machine is equipped with a fixed ROPS, al-

ways wear seatbelt.

nn

nn

n If machine is equipped with a foldable ROPS,

always wear seatbelt when ROPS is de-

ployed.

nn

nn

n Be certain that the seatbelt can be released

quickly if the machine is driven or rolls into

ponds or water.

nn

nn

n Check carefully for overhead clearances

such as, branches, doorways, or electrical

wires, before driving under any objects

and do not contact them.

STOPPING THE ENGINE

nn

nn

n Set the throttle at

1

/3 open. Allow engine to

idle at this setting for several minutes, then

move the throttle to slow idle.

nn

nn

n Move ignition switch to “OFF” position (up-

right) and remove key.

Always remove key from ignition

switch when leaving unit unattended or

when not in use.

Emergency shutdown of engine:

If the engine does not stop running with the

throttle at slow idle and the starter switch in the

“OFF” position, the following procedure will stop

the engine.

nn

nn

n Unplug the wires from the fuel shut-off sole-

noid (item 30, page 33).

nn

nn

n Push the engine stop lever forward toward

the radiator (refer to the Engine Manual’s il-

lustration showing the location of the engine

stop lever).

nn

nn

n It is important that the operator be familiar with

where the parts are located on the engine.

MOVING UNIT WITHOUT POWER

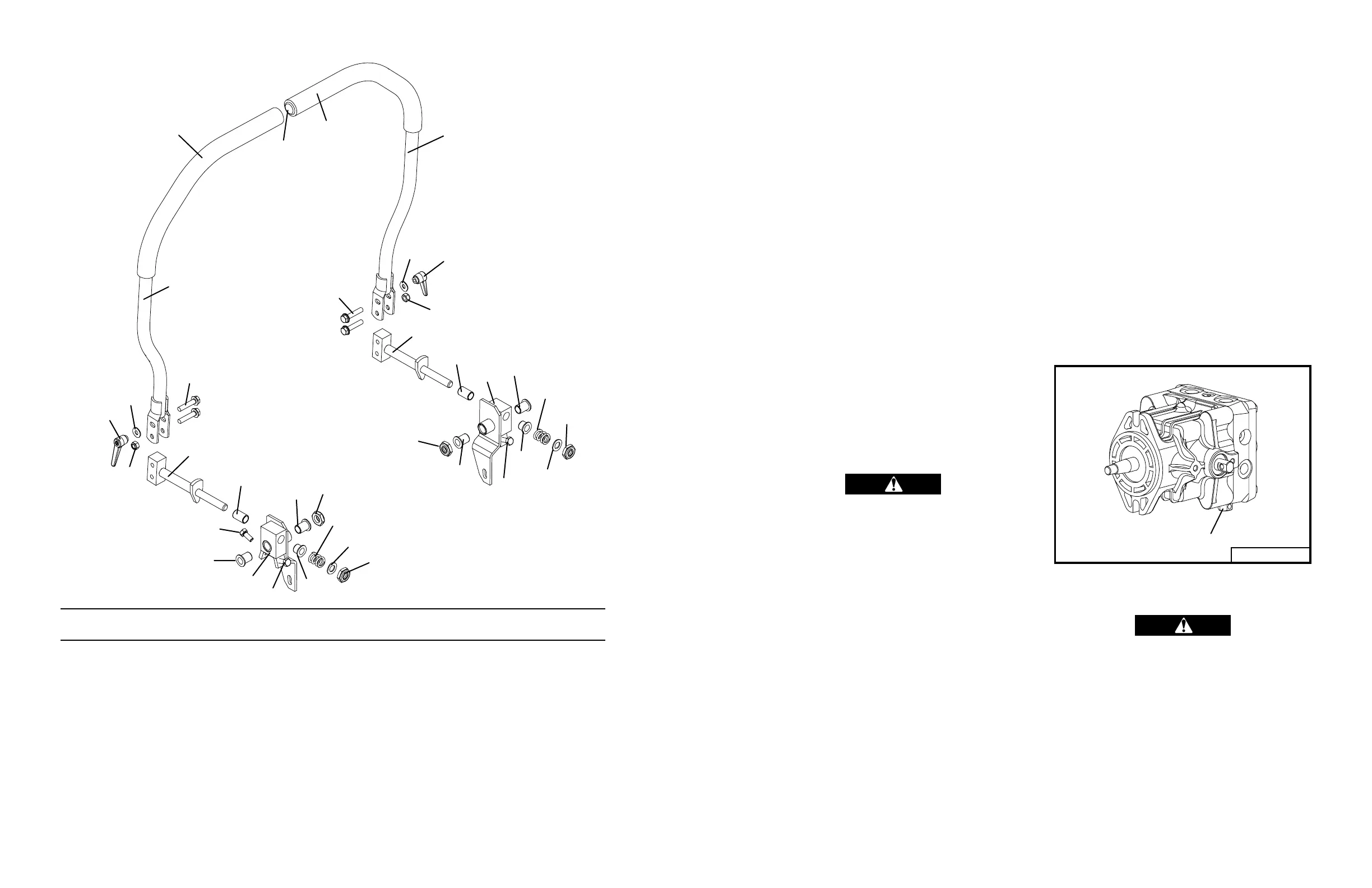

The hydro pumps are equipped with a dump valve

(Refer to Fig. 3) that allows the unit to be moved

without power by deactivating the pump. With the

dump valve lever in normal operating position

the fluid in the pump will make it difficult to

move the unit (even with the steering levers in

neutral position). The dump valve is located on

the bottom toward the right front of each hydro

pump. Activate the dump valve by rotating

counter-clockwise with a .625 inch wrench. Ro-

tate one revolution. When BOTH hydro pumps

are deactivated the unit becomes “freewheeling”

allowing it to be moved. Before the hydro pumps

become operational the dump valves must be

returned to their normal operating position.

Do not tighten above 120 in lbs (10 ft lbs)

(14Nm) maximum.

STEERING LEVER OPERATION

(refer to Fig. 4, page 21)

Do not move steering levers from

forward to reverse or reverse to

forward position rapidly. The sudden

change could cause loss of control or

damage to equipment.

The Grasshopper tractor is very

unstable without an attachment.

Move very slowly when attachment is

removed. Never carry passengers.

Fig. 3

Dump Valve

01096

38

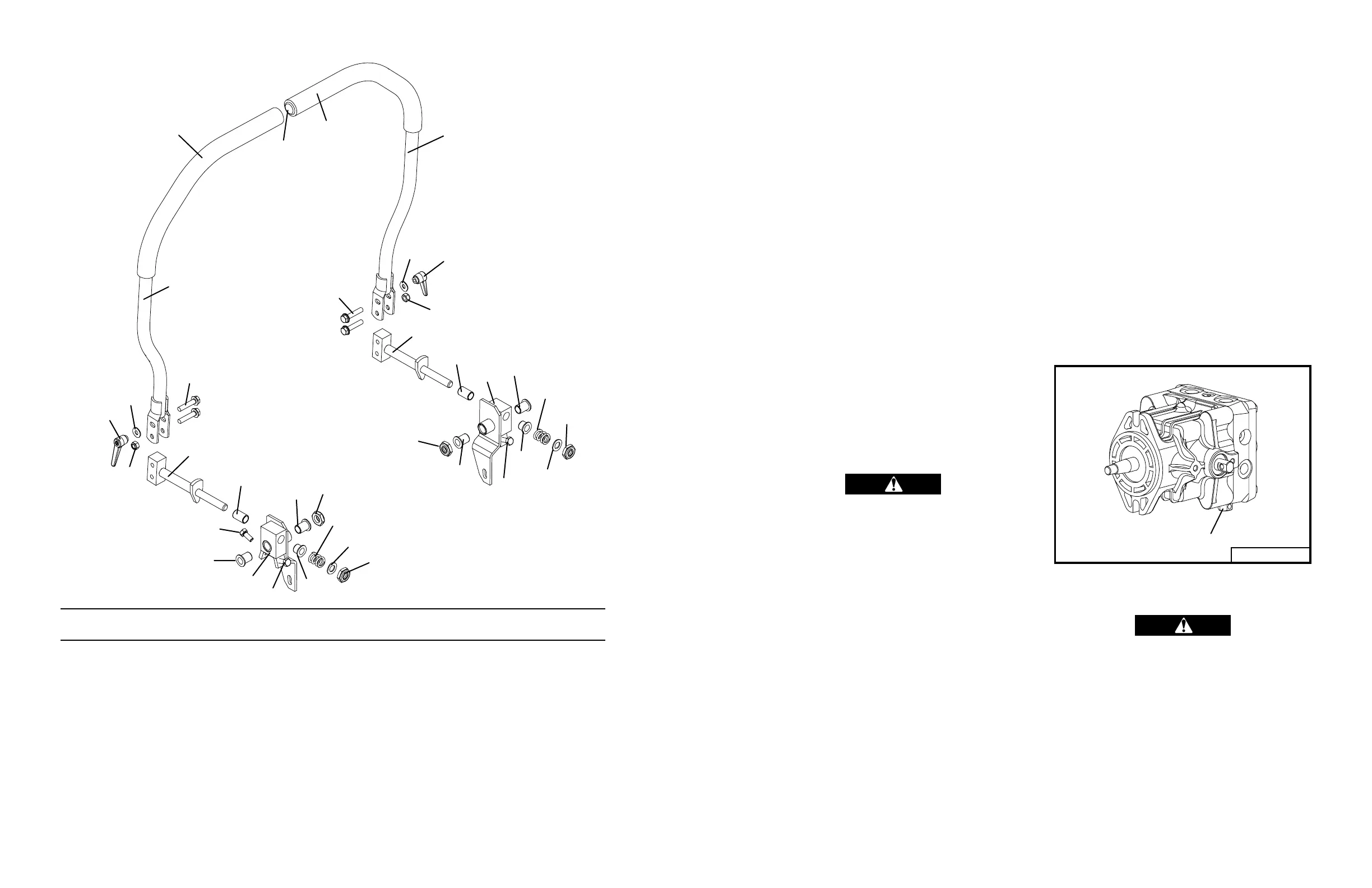

STEERING ASSEMBLY

1 604778 Steering Lever Assembly

(includes item 5 and 6)

2 643926 Steering Lever Mount

3 253195 Hex Whiz Bolt

4 253450 Nut -Nylon Insert

5 422179 Handle Grip - Foam

6 422095 Vinyl Cap

7 604771 Steering Pivot Rt. w/Stop & Bearings

8 604772 Steering Pivot Lt. w/Stop & Bearings

9 422559 Bearing w/Flange

10 422557 Bearing

11 257019 Washer

12 257063 Nylon Washer

13 422556 Bearing w/Flange

14 283324 Compression Spring

15 253470 Nut- Nylon Insert

16 243197 Stop Bolt

17 254438 Nut Adj. Lever

ItemItem

ItemItem

Item

OrderOrder

OrderOrder

Order

DescriptionDescription

DescriptionDescription

Description

No.No.

No.No.

No.

No.No.

No.No.

No.

ItemItem

ItemItem

Item

OrderOrder

OrderOrder

Order

DescriptionDescription

DescriptionDescription

Description

No.No.

No.No.

No.

No.No.

No.No.

No.

97023D

1

1

2

2

3

3

4

4

5

5

6

7

8

9

9

9

10

10

9

16

12

12

13

13

14

14

15

15

15

15

16

16

97023D

17

17

11

11

Loading...

Loading...