20

ADJUSTMENTS AND TROUBLESHOOTING

WARNING

When completing a maintenance

function, make sure all shields are in

good condition and are installed

before placing unit back into use.

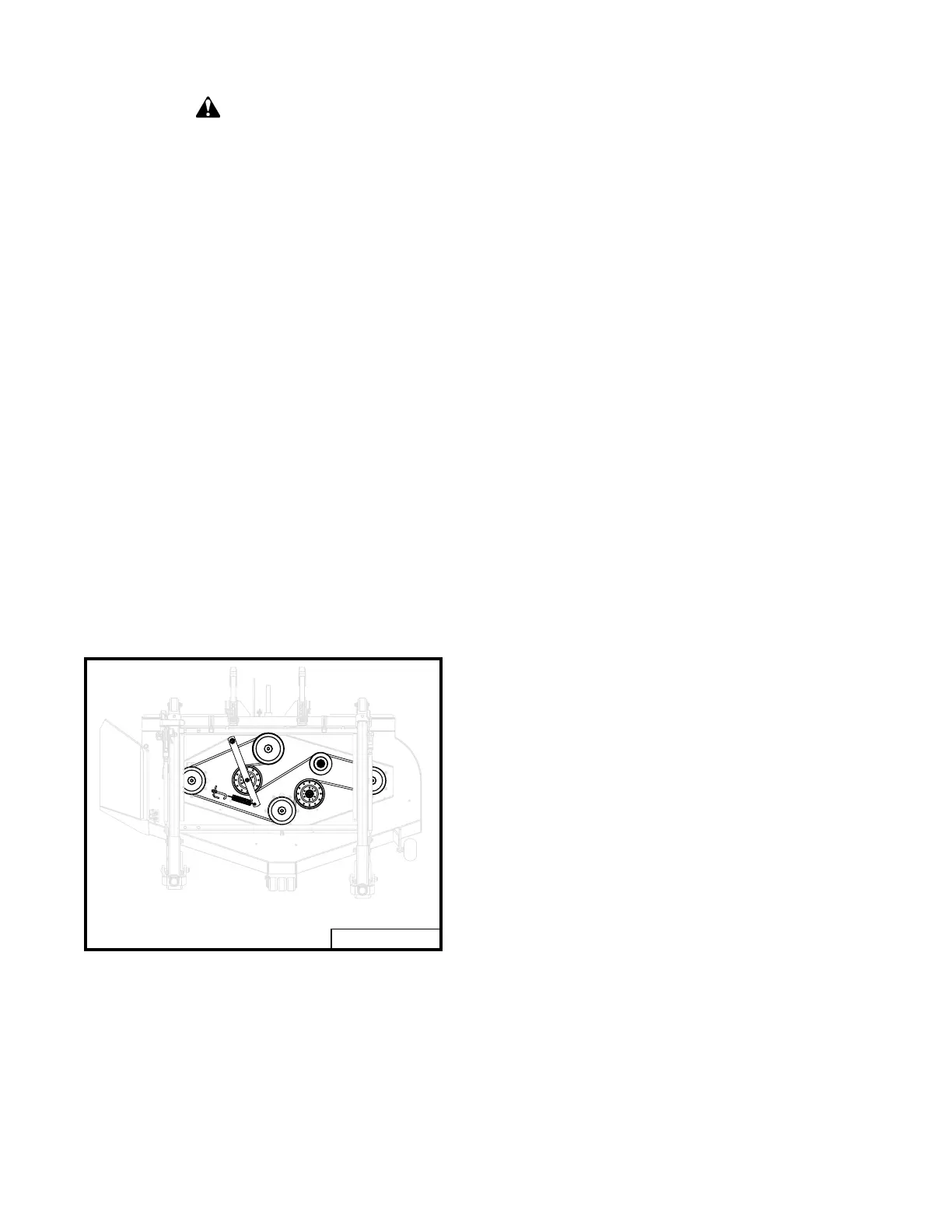

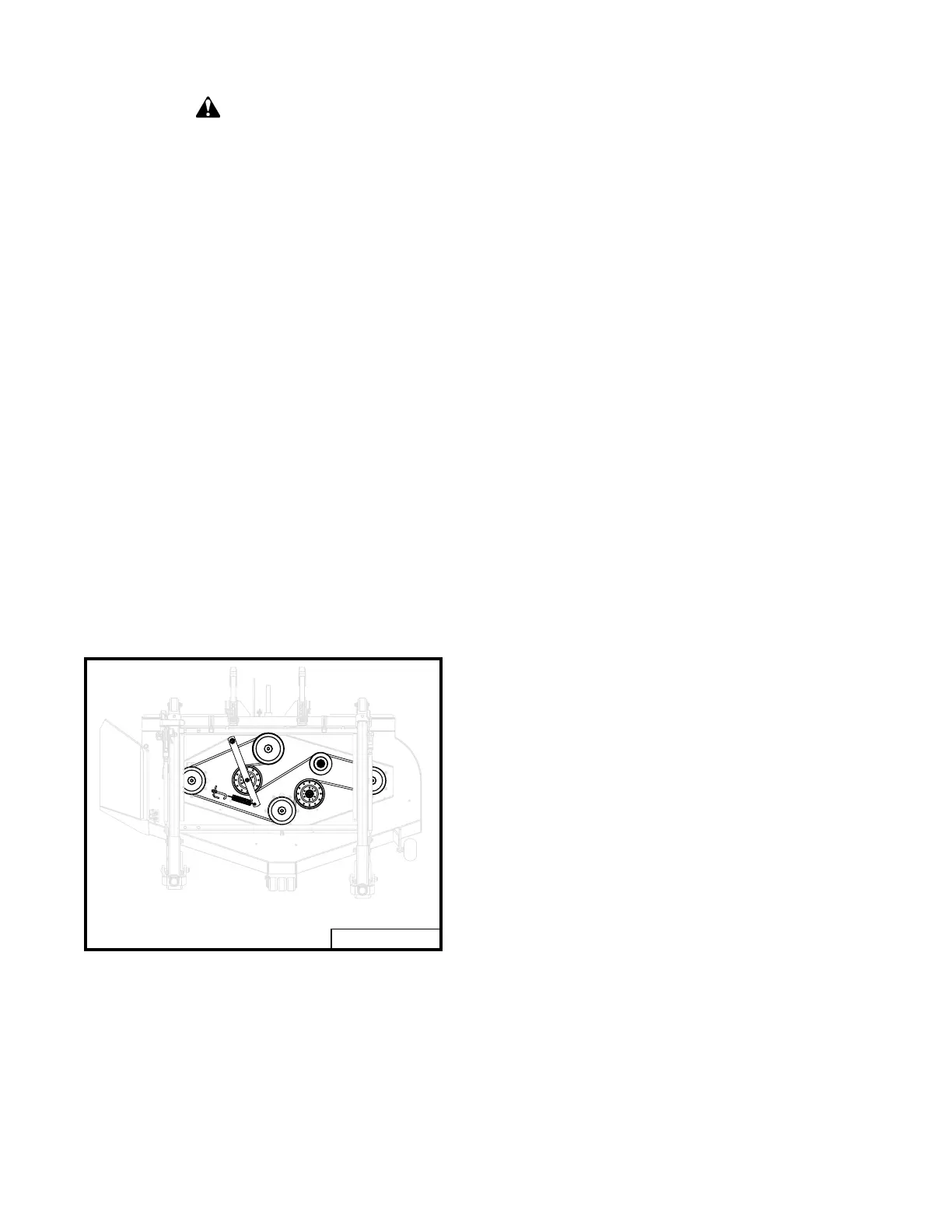

BELT REPLACEMENT

(refer to Fig. 15)

Major causes of belt failure are improper instal-

lation and tension. Before installing a new belt,

check spindle shafts and bearings for excessive

end play and wear by moving each spindle shaft

side to side and up and down. Be sure they turn

smoothly and freely. Make sure idlers are still

aligned with spindle sheaves. Check sheave

grooves for cleanliness and wear. If grooves re-

quire cleaning use a cloth moistened a with

nonflammable nontoxic degreasing agent or

commercial detergent and water.

Avoid excessive force during installation. Do

not use tools to pry belt on or roll belt over

sheaves. This can cause hidden damage and pre-

mature belt failure.

Fig. 15

S L 9 8 5 2 / S L 9 8 6 1 D e c k

0 0 0 4 4

1. Loosen the lock nut and back-off the draw

nut until tension is released from the old belt

and it can be lifted off the deck sheaves.

2. Install the new belt following the illustration

for proper belt routing.

3. Reset the belt tension using the procedure in

the “Belt Adjustment” section on the previ-

ous page.

Loading...

Loading...