GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

164

IDU project numbers in all systems will automatically deviate. The conflict will be solved in about 1

minute and the system will work properly.

The automatic deviation function only works when it is enabled on the controlling unit in the system,

of which the centralized control address is 00000.

Note: When there are only a few conflicting IDUs, manual setting is recommended. This method

only applies to conflicting IDUs and does only affect other IDUs' project numbers.

In case of many conflicting IDUs, auto deviation is recommended. This method is faster, but may

change project numbers of normal IDUs. This method applies for the first commissioning after

installation.

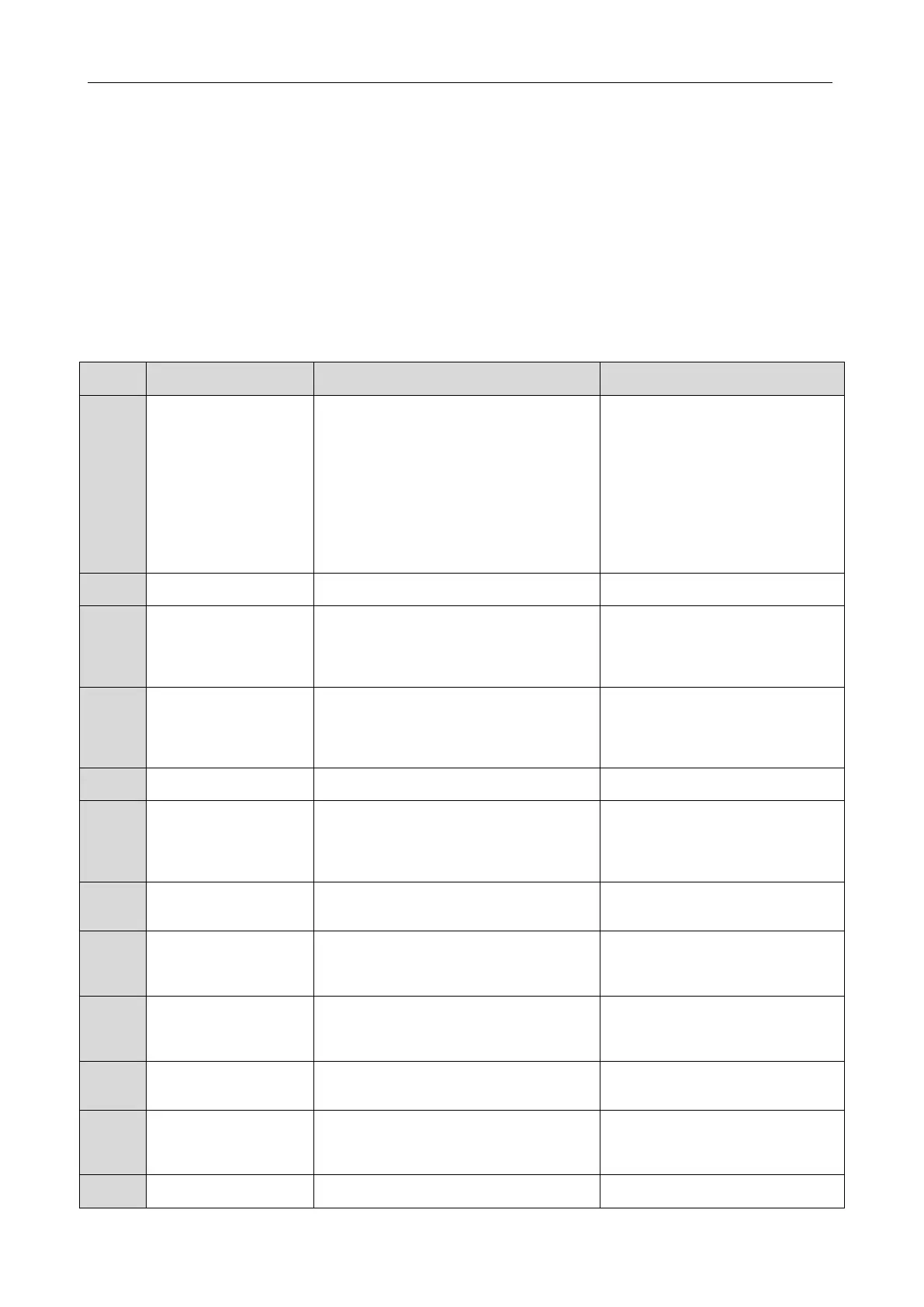

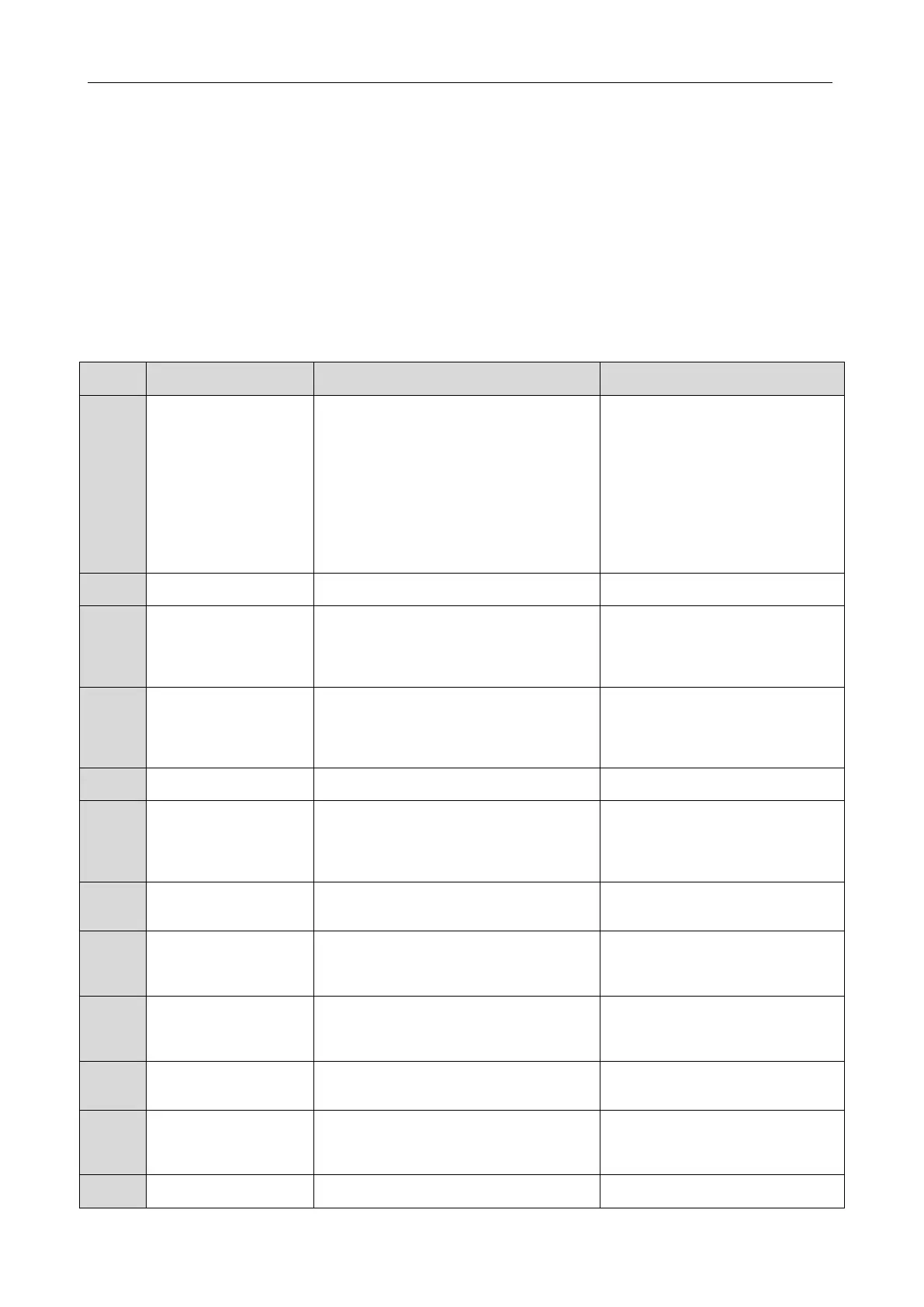

Communication failure

between main control

board and inverter

compressor drive

1. The control board is powered off;

2. The compressor drive board is powered

off;

3. The communication cable between the

control board and compressor drive board

is not connected;

4. The compressor drive board's dial switch

SA201 is wrong.

1. Check the power supply of the

control board. Replace the control

board if it works properly;

2. Check the power supply of the

drive board. Replace the drive board

if it works properly;

3. Connect the main board and drive

board using the communication

cable;

4. Adjust the dial switch of the

compressor drive board.

Compressor drive

module reset protection

1. The compressor drive board is faulty.

1. Replace the compressor drive

board.

Inverter compressor

over-current protection

1. The drive board's IPM module is

damaged;

2. The compressor's UVW cable is not

connected properly;

3. The compressor is damaged.

1. Replace the compressor drive

board;

2. Reconnect the compressor's UVW

cable;

3. Replace the compressor.

Compressor drive IPM

module protection

1. The drive board's IPM module is

damaged;

2. The compressor's UVW cable is not

connected properly;

3. The compressor is damaged.

1. Replace the compressor drive

board;

2. Reconnect the compressor's UVW

cable;

3. Replace the compressor.

Compressor drive

temperature sensor fault

1. The compressor drive board is faulty.

1. Replace the compressor drive

board.

Compressor drive IPM

over-temperature

protection

1. The compressor drive board is faulty;

2. Thermal gel is not applied evenly on the

IPM module;

3. The IPM module is not screwed properly.

1. Replace the compressor drive

board;

2. Apply thermal gel evenly on the

IPM module;

3. Screw the IPM module properly.

Inverter compressor

out-of-step protection

1. The compressor drive board is faulty.

2. The compressor is damaged.

1. Replace the compressor drive

board.

2. Replace the compressor.

Compressor drive DC

bus high voltage

protection

1. Does the voltage of the input power

cable of the whole system exceed 465 V;

2. The compressor drive board is faulty.

1. Lower the voltage of the input

power cable to the required range;

2. Replace the compressor drive

board.

Compressor drive DC

bus low voltage

protection

1. Is the voltage of the input power cable of

the whole system lower than 200 V;

2. The compressor drive board is faulty.

1. Elevate the voltage of the input

power cable to the required range;

2. Replace the compressor drive

board.

Compressor drive

current check circuit

fault

1. The compressor drive board is faulty.

1. Replace the compressor drive

board.

Compressor drive

recharging circuit fault

1. Is the voltage of the input power cable of

the whole system lower than 200 V;

2. The compressor drive board is faulty.

1. Elevate the voltage of the input

power cable to the required range;

2. Replace the compressor drive

board.

Inverter compressor

starting failure

1. The drive board is damaged;

2. The compressor's UVW cable is not

1. Replace the compressor drive

board;

Loading...

Loading...