GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

224

wiring are correct. You are advised to replace them one after another.

NOTE:

Keep wiring identical to factory installation. Control varies with compressors. Wrong wiring

or inverse connection of the compressors may cause damage to units.

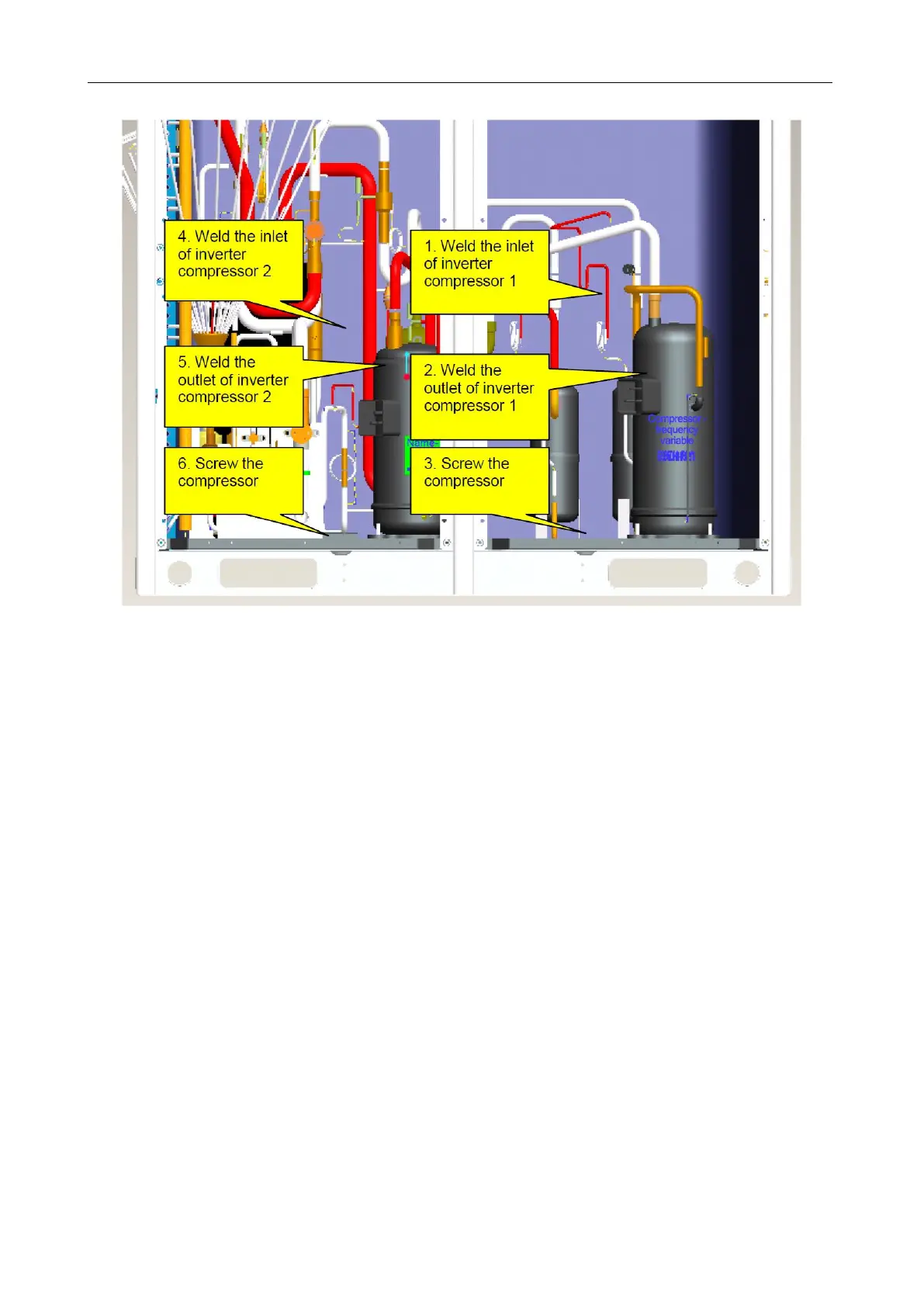

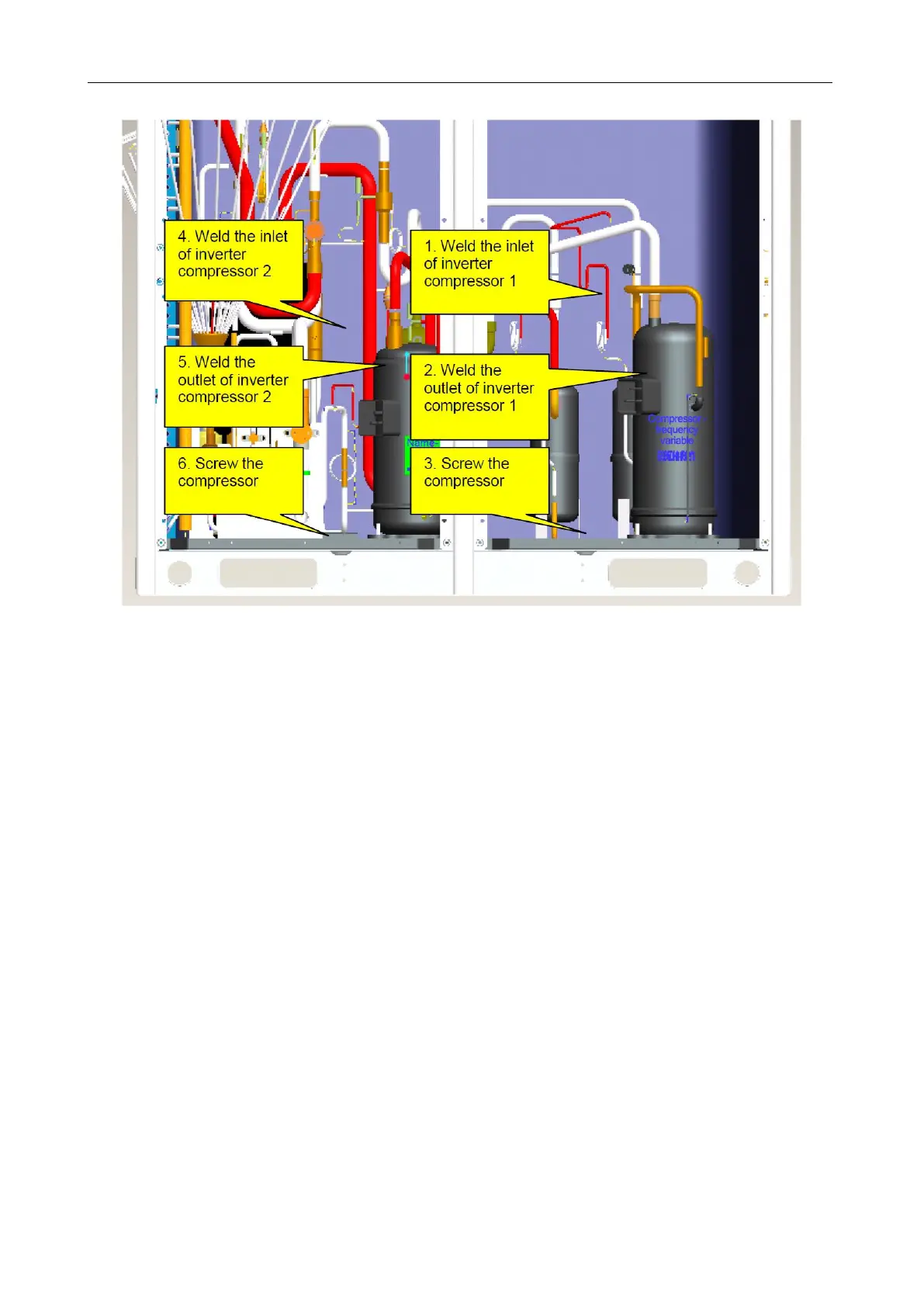

Cautions on replacement of compressors:

1) Before installing new compressors, remove the sealing rubbers and weld the compressors with

corresponding pipes. During welding, charge nitrogen into the pipes. Since compressors‘ suction and

discharge pipes are made of copper plated steels, you need to prepare special welding rods (containing

5% or more silver). Welding clearance should be controlled within 0.1~0.3mm, avoiding blockage or

loose welding. During welding, control pipe openings from being over-heated.

2) After the pipeline system is welded, use special supports and bolts to fix the compressors,

ensuring stability of the compressors during running.

3) Power lines of the compressors should be wired following the factory installation. You can refer

to the wiring diagram. Phase sequence error and inverse connection of compressors are not allowed.

Step 12: System check.

1) Check welding joints for abnormalities.

2) Charge nitrogen into the system for leakage detection. If you are maintaining ODUs and the IDU

system is normal, you can charge nitrogen into the ODU system only. Note that nitrogen should be

charged from both the high pressure side and low pressure side. You are advised to charge through all

valves. Nitrogen pressure should be larger than 2.0Mpa(290psi

)

. Then, charge soapsuds into the

system and check specially the weld joints for leakage.

3) Finally, charge nitrogen into the system again for pressure check. Close all valves and keep

Loading...

Loading...