GMV DC Inverter VRF

33

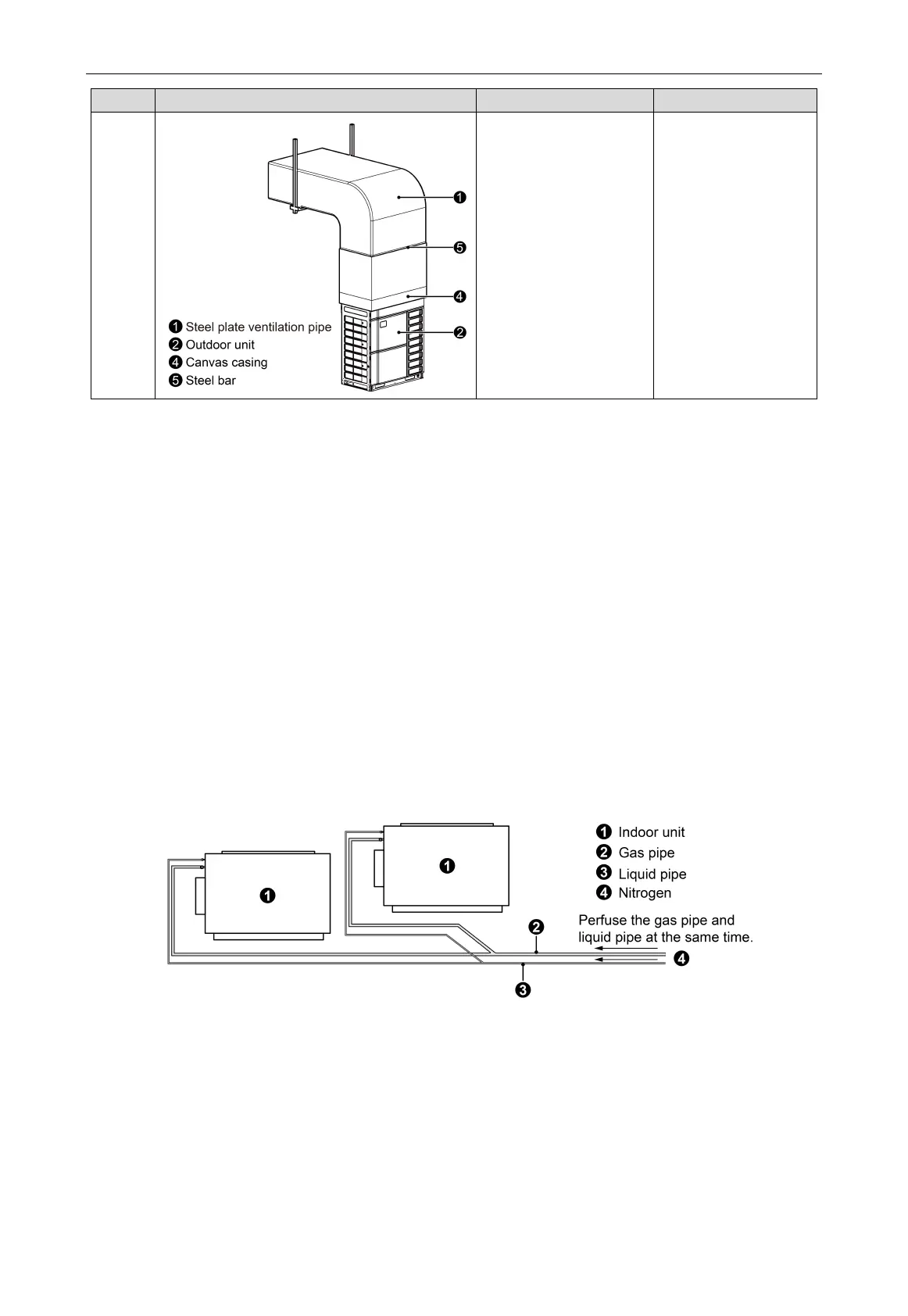

Step 4

1) Pull the canvas casing

upside down and press

it on the butt flange of

the steel pipe

ventilation pipe with

steel bars;

2) Drill holes with the

manual drill and fix

them with self-

tapping screws;

3) Seal the two butt joints

with tinfoil panel and

check the reliability of

the connection.

—

3.6 Vacuum and Drying of Refrigeration System

3.6.1 Air Tightness Test

(1) Notices

1) The range of test pressure gauge for R410A system should be above 4.5MPa.

2) Record the pressure gauge readings, ambient temperature and test time.

3) Pressure correction: The temperature changes by 1

℃

, and the pressure changes by 0.01

MPa.

4) The pressure should remain unchanged to be qualified.

5) If it is necessary to maintain pressure for a long time, the pressure should be reduced to

0.5 MPa or less. Long periods of high pressure can cause leakage at the weld site and

there is safety hazard.

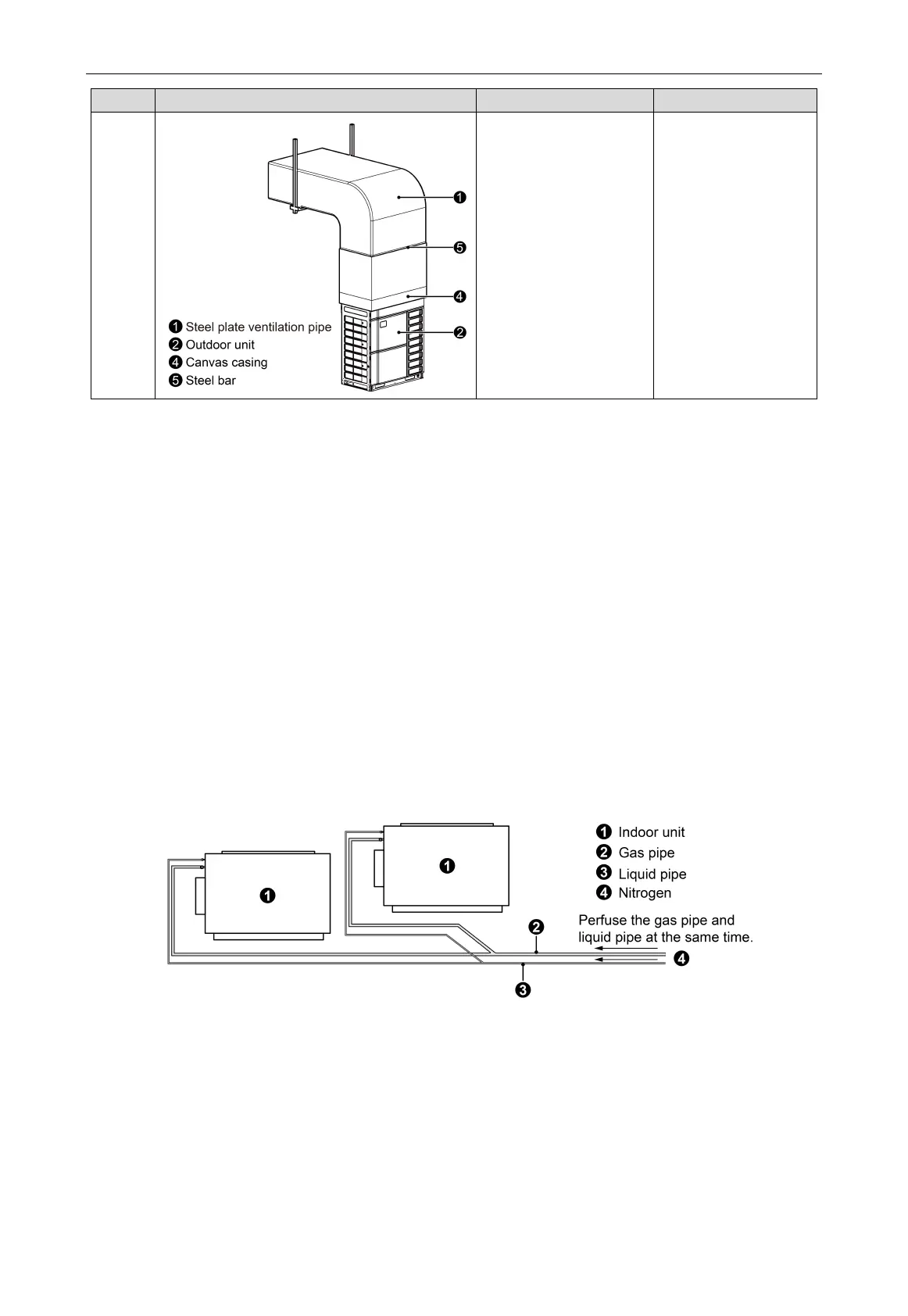

6) Before the air tightness test for the refrigerant pipe is completed, it is not allowed to

conduct the insulation and wrapping work for any joints between the welding point and the

bell mouth of indoor unit. Please increase pressure from the outdoor side pipes at the

same time. It is forbidden to increase pressure from one side pipe:

Fig.3.6.1

Note:

All welding points can’t be heat-insulated and wrapped until the air tightness test is

completed.

(2) Operation procedures for the air tightness test

When leaving the factory, gas pipe, liquid pipe and cut-off valve of outdoor unit have been closed.

Please confirm it during installation.

Before the test, a small amount of lubricant oil required by the corresponding system should be

smeared at the nut and the end of the pipe. Two wrenches should be used when fixing the nut.

Loading...

Loading...