51

DC Inverter Multi VRF System II

Service Manual

DEBUGGING & MAINTENANCE

1 Debugging of Unit

Caution:

① .

After the initial installation is nished and the main board of outdoor unit is replaced, it must perform debugging. Otherwise, the unit

can’t operate.

② .

The debugging must be performed by professional person or under the the guide of professional person.

1.1 Preparation for debugging

(1) Do not disconnect the power before the installation is nished,

(2) All wires for controller and electric wires must be connected correctly and reliably.

(3) Check the the xing ring of the foot of compressor for transportaion is removed.

(4) Remove all sundries from the unit, such as metal chips, joint, forceps holder, and so on.

(5) Check whether the appearance and pipeline system are damaged during carry or transportation process.

(6) Calculate the required added refrigerant-charging volume according to the length of pipe of system and pre-charge the refrigerant.

If refrigerant can’t be added any more when the required refrigerant-charging volume hasn’t been reached, record to refrigerant

volume which still needs to be added and continue to add refrigerant during run test operation process. Please refer to below run

test for the refrigerant-adding stage during run test process.

(7) After adding refrigerant, please make sure the valve for outdoor is opened completely.

(8) For the convenient of troubleshooting, the unit can’t be connected to the PC which installed with related debugging software and

make sure that the the datas in real time of this unit can be inspected by this computer. Please refer to Service Manual for the

installation and connection of the bebugging software.

(9) Before turn test, please do make sure that the preheat time for compressor is 8h above and touch the compressor to see whether

preheat is normal. You can perform run test only after normal preheat. Otherwise, it may damage the compressor.

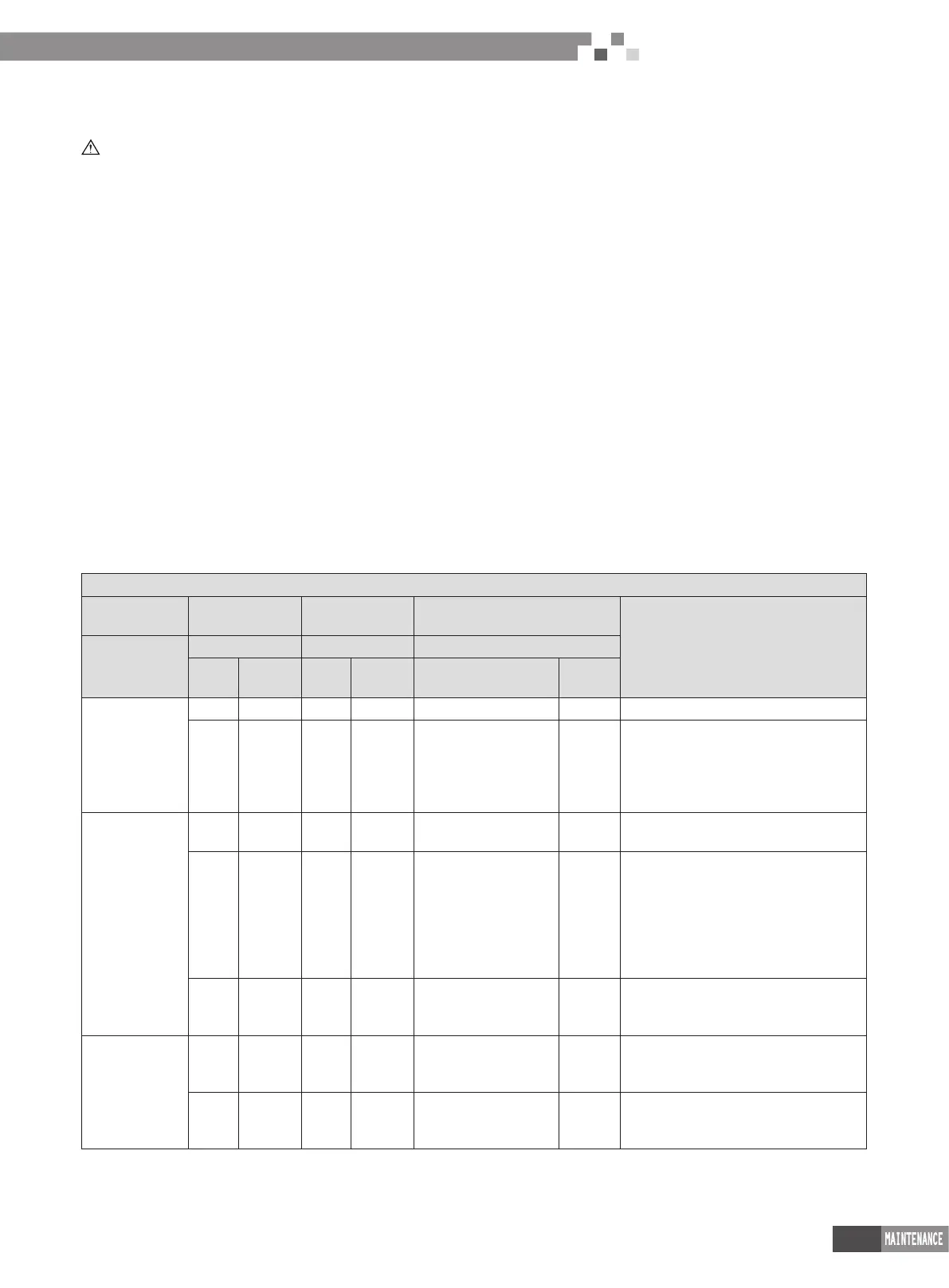

1.2 Debugging of unit

Debugging procedure for test run, display instruction for indicator on main board of outdoor unit and operation method are as below:

Stage process instruction for debugging

—— Debugging code

Process code

Status code

Code instruction and operation method

Process

LED1 LED2 LED3

Code

Display

status

Code

Display

status

Code

Display

status

01_ Main

control unit

setting

db ON 01 ON AO ON No debugging status for system

db ON 01 ON OC ON

Press SW7 button on main board for 5s

to start system debugging. The indicator

on main board is displayed as shown

in the left. 2s later, it will enter into next

step determination.

02_ Address

distribution

db ON 02 ON Ad Flash

Address distribution for the system. 10s

later, the display is as below:

db ON 02 ON L7 Flash

No main indoor unit. Display will be

kept for 1min. Within 1min, set the

main indoor unit through debugging

software. If notset the main indoor

unit by hand within 1min, the system

will automatically set the minimum IP

address as the main indoor unit.

db ON 02 ON OC ON

The distribution for the system address

is nished. 2s later, it will enter into the

next step determination automatically.

03_Quantity

conrmation of

outdoor unit

db ON 03 ON 01 Flash

Cormation process of system. 1s

later, it will enter into the next step

automatically.

db ON 03 ON OC ON

Cormation process of system. 2s

later, it will enter into the next step

automatically.

Loading...

Loading...