Maximum Max Overall Size

Damper

Single-Section for Multi-Section

Model Size Dampers

DFD-230 36

x 36 or 32 x 48 64 x 48

DFD-210 36 x 36 or 32 x 50 64 x 50

DFDTF-210 32 x 36 96 x 72

DFDTF-210 32 x 50 64 x 50

FSD-211, 212, 213 36 x 48 or 32 x 50

FSD-311,311M, IMO-311 32 x 50

FSD-312, 312M 32 x 50

IMO-311 32 x 36

FSD-231 36 x 36 or 32 x 48 72 x 48

SEFSD-211/SEDFD-210 24 x 30 48 x 30

SSFSD-211/SSDFD-210 24 x 30 48 x 30

IMO-310,DFDAF-310 32 x50 NA

NOTE: FSD model dampers fitted with a fusible link

closure device are limited to single section sizes.

Dampers with a fusible link and spring assembly closure

device may not be used for multiple section applications.

The damper sections must be attached together with #10

(

3

/4 in. max.) sheet metal screws,

1

/4 in. diameter nuts and

bolts, tack or spot welds, or

3

/16 in. diameter steel pop

rivets. Attachments must be spaced a minimum of 6 in.

on centers and a maximum of 2 in. from corners. (see

Fig. 3) Attachments must be made on front face and

back face (air entering and air exiting side) of damper

sections.

5

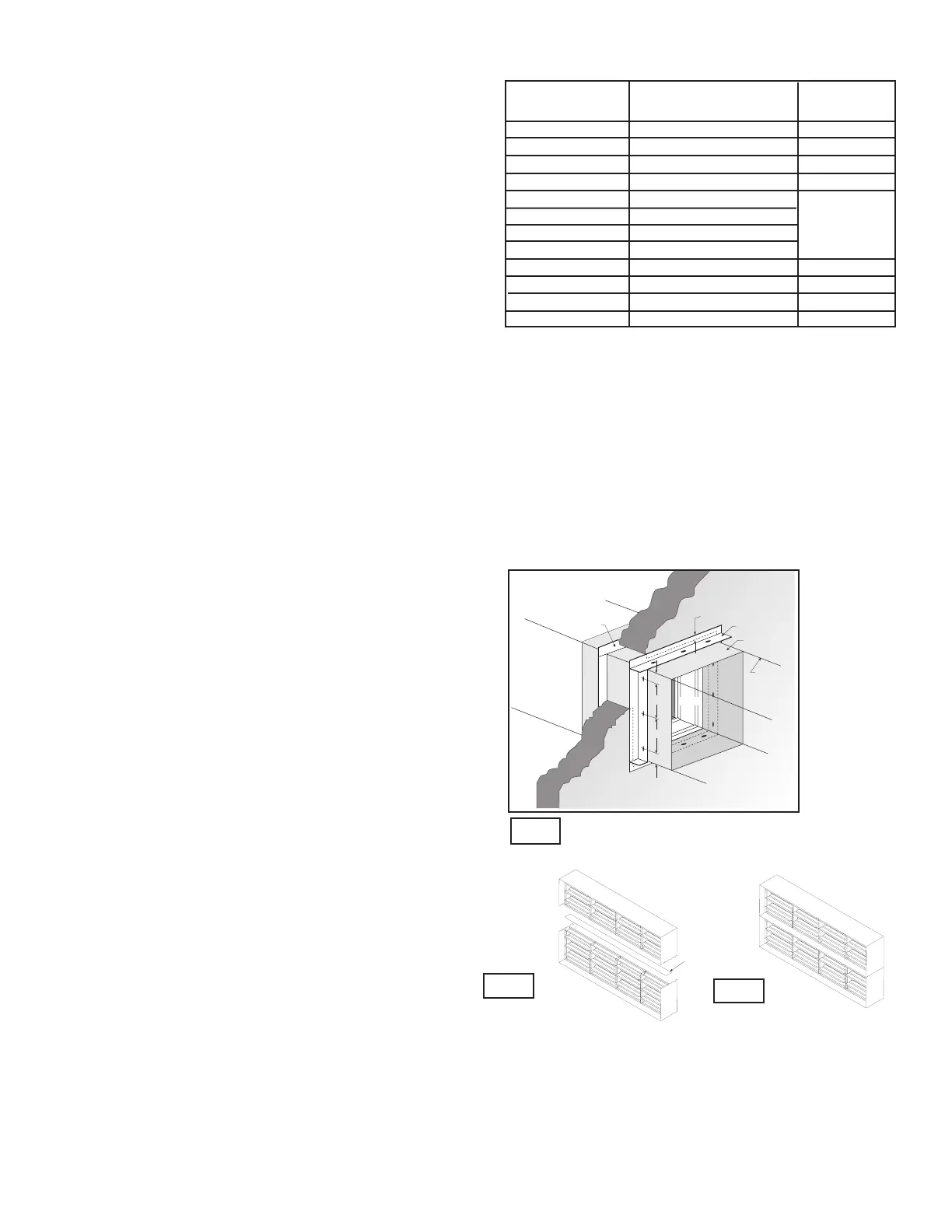

4. SECURING THE DAMPER/SLEEVE ASSEMBLY

TO WALL AND FLOOR OPENINGS (continued)

A minimum of two connections per side, top, and

bottom, 12 in. O.C. maximum for openings of 48 in. W

x 36 in. H and less, and 6 in. O.C. for openings 80 in. W

x 50 in. H, 50 in. W x 72 in. H, and 40 in. W x 72 in. H or

less. The angles must be attached to all 4 sides of the

sleeve. Ensure that attachment device does not interfere

with the operation of the damper and the free movement

of the damper blades. The angles need not be attached

to each other at the corners. Do not secure the retaining

angle to the fire separation.

• Retaining angles must completely cover the

clearance space between the damper and the

wall/floor opening, plus overlap the wall/floor

a minimum of 1 in. This coverage includes all

corners.

• Retaining angles should not be fastened to

the wall/floor material. The angles should only

sandwich the wall/floor and allow for damper

expansion during periods of intense heat.

5. ACTUATOR CONNECTIONS

Electrical and/or pneumatic connections to damper

actuators should be made in accordance with wiring and

piping diagrams developed in compliance with applicable

codes, ordinances and regulations (see Electrical

Guidelines).

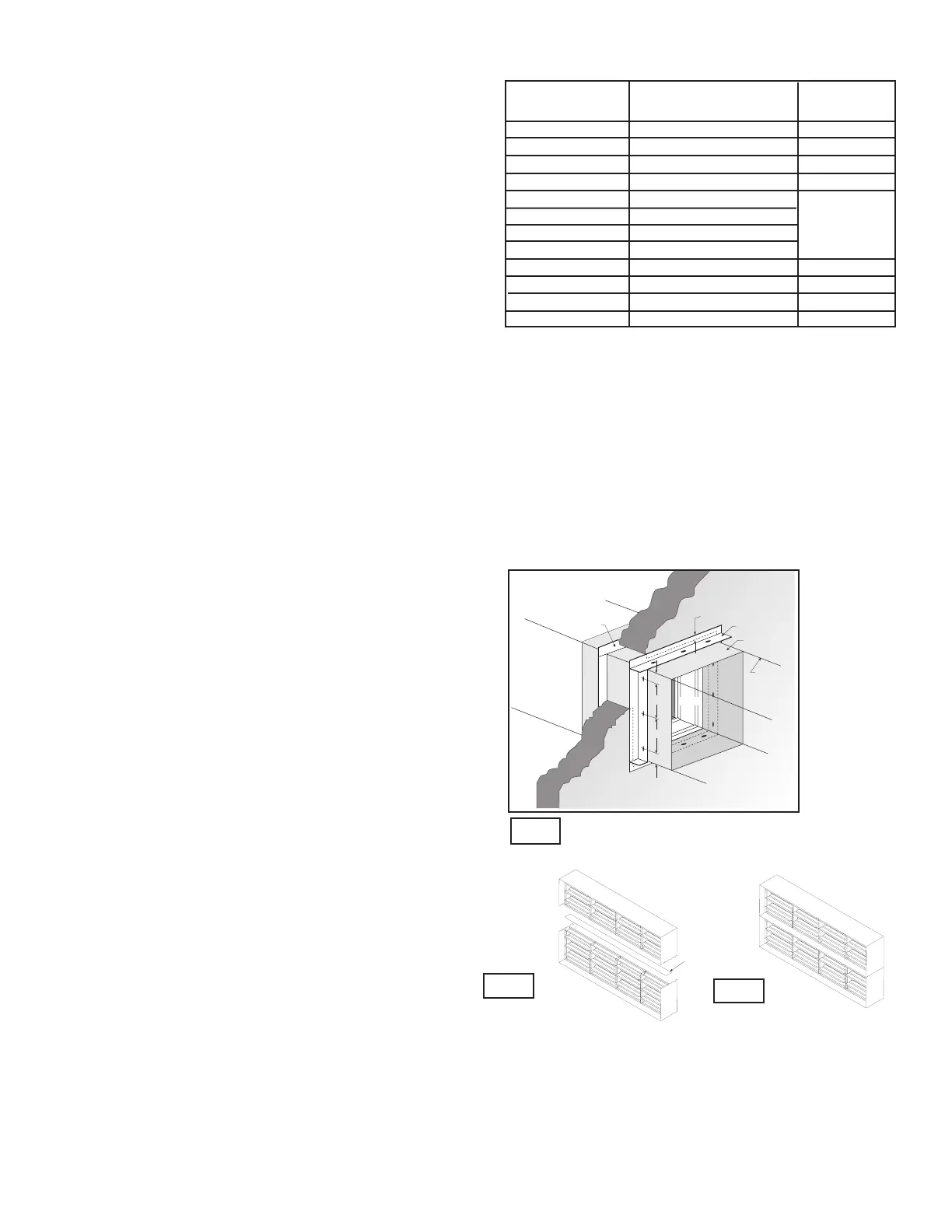

6. INSTALLING MULTIPLE DAMPER SECTION

ASSEMBLIES

A damper assembly is not restricted to a maximum

number of sections, but must not exceed the section

sizes and overall sizes shown (see chart).

Two section high dampers require reinforcement using a

14 gauge, 5 in. wide mullion as shown in Figure 4 below,

or two individually sleeved units stacked vertically, shown

below in Figure 5. When using two individually sleeved

units, the sleeve acts as the mullion, therefore no mullion

is required.

Note: Dampers ordered for individual installation may

not be installed together. The full assembly size must be

specified at the time the dampers are ordered.

7. CONNECTION AND OPERATION OF

TEMPERATURE RESPONSE DEVICES (RRL

STANDARD, OCI OPTION, AND TOR OPTION)

RRL - Dampers will be supplied with a thermostat-type

temperature response device, as a standard. The device is

a RRL (resettable link device), which only incorporates one

thermostat and therefore the damper remains closed as

soon as its sensor temperature is reached. The RRL does

not contain blade indication switches. Refer to Figure 6 for

wiring of the RRL thermostat.

OCI - The OCI (open or closed indicator) option contains

a single pole, double throw switch used to indicate the

damper blade position. The switch provides a positive open

or closed signal when used in conjunction with remote

indicator lights. Refer to Fig. 7 for wiring of the OCI option.

Vertical Mount

IN

-

AX

IN

-

AX

3LEEVE

2ETAINING

!NGLE

$AMPER

$UCT

-ININ

/VERLAP

7ALLOR

&LOOR

2ETAINING

!NGLE

ONLYAPPLICABLEFORDAMPERSIZESABOVEINXIN

IN

-

AX

IN

-

AX

Both vertical and horizontal damper installations are typified by these drawings.

Fig. 3

128 x 100

GA

INWIDE

3UPPORT

-ULLION

Fig. 4

Fig. 5

Single Sleeve Around

Outside with Support

Mullion

Two Individually Sleeved

Units with No Mullions

Loading...

Loading...