6

RATINGS

Integral Switch Type: Single Pole, double throw

Electrical Capacity: 10 Amps,

1

/3 hp, 120 or 240 Vac

1

/2 Amp, 125 Vdc;

1

/4 Amp 250 Vdc

5 Amps, 120 Vac “L”

(lamp load)

1.0 Amps, 24 Vac

1.5 Amps, 24 Vdc

Temperature Limit: 165°

F (standard primary sensor)

212°

F (optional primary sensor)

250°

F (secondary sensor)

350°

F (secondary sensor)

RATINGS (Fig. 8)

Integral Switch Type: Single Pole, double throw

Electrical: 10 Amps,

1

/3 hp, 120 or 240 Vac

1

/2 Amp, 125 Vdc;

1

/4 Amp 250

Vdc 5 Amps, 120 Vac “L” (lamp

load)

1.0 Amps, 24 Vac

1.5 Amps, 24 Vdc

Temperature Limit: 165° F (standard primary sensor)

212°

F (optional primary sensor)

250°

F (secondary sensor)

350º F ( secondary sensor)

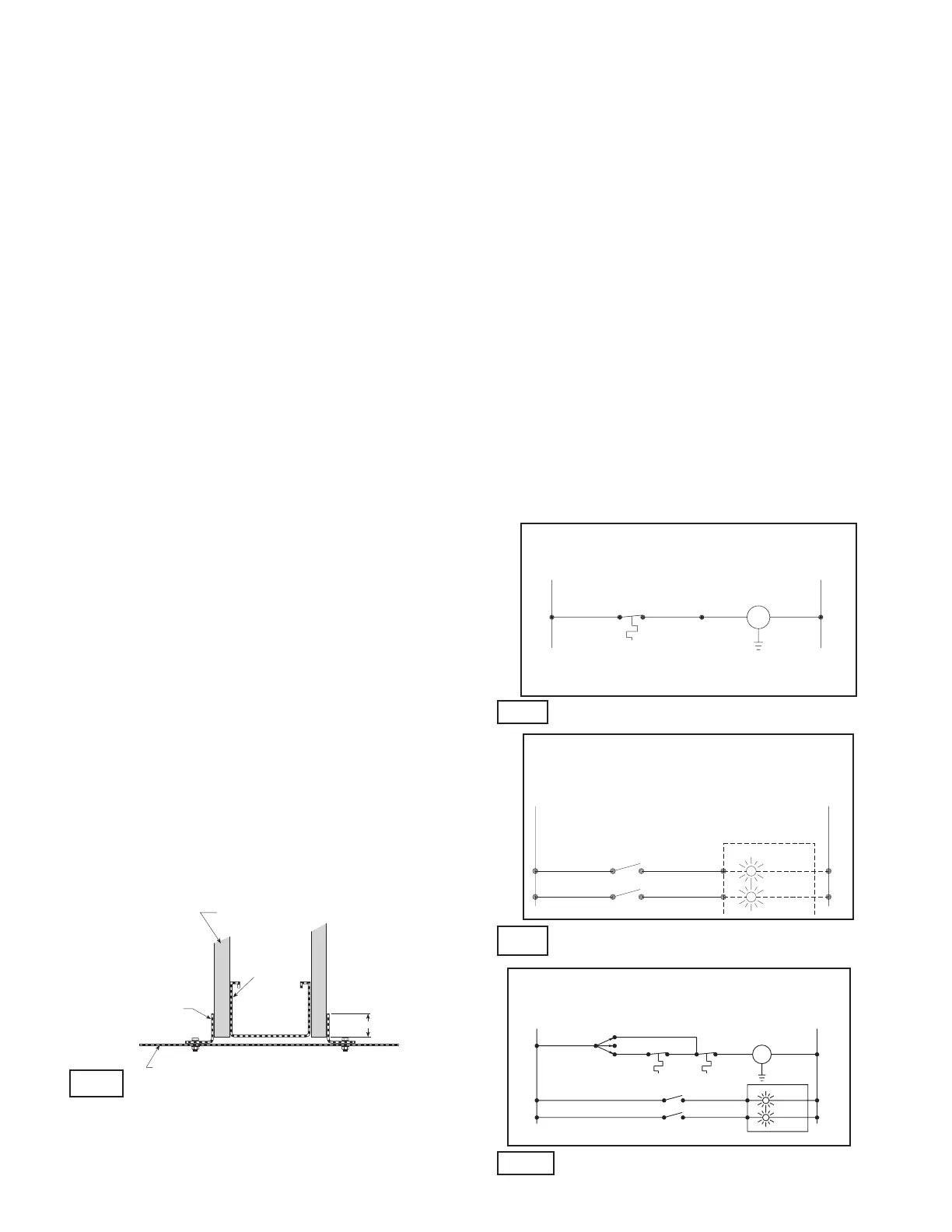

L1

DAMPER

INDICATOR

LIGHTS

ELECTRIC DAMPER

ACTUATOR OR PNEU. SOLENOID

VALVE

M

L2

BROWN

YELLOW

YELLOW

ORANGE

HL=HIGH LIMIT SENSOR

P=PRIMARY TEMP SENSOR

OR = OVERRIDE

OR

ON

OFF

BY OTHERS

WHITE

NC

YELLOW

YELLOW

S1

S2

NO

NO

P

NC

BROWN

HL

BLACK

CLOSED POSITION OF THE DAMPER.

A BLUE MARKER INDICATE THE

THE SWITCH WIRES WRAPPED WITH

ELECTRICAL CAPACITY = 10AMP @ 120 / 240 VAC

NOTE:

OPEN-CLOSED INDICATOR

TEMPERATURE LIMITED OVERRIDE/

TOR Wiring

Fig. 8

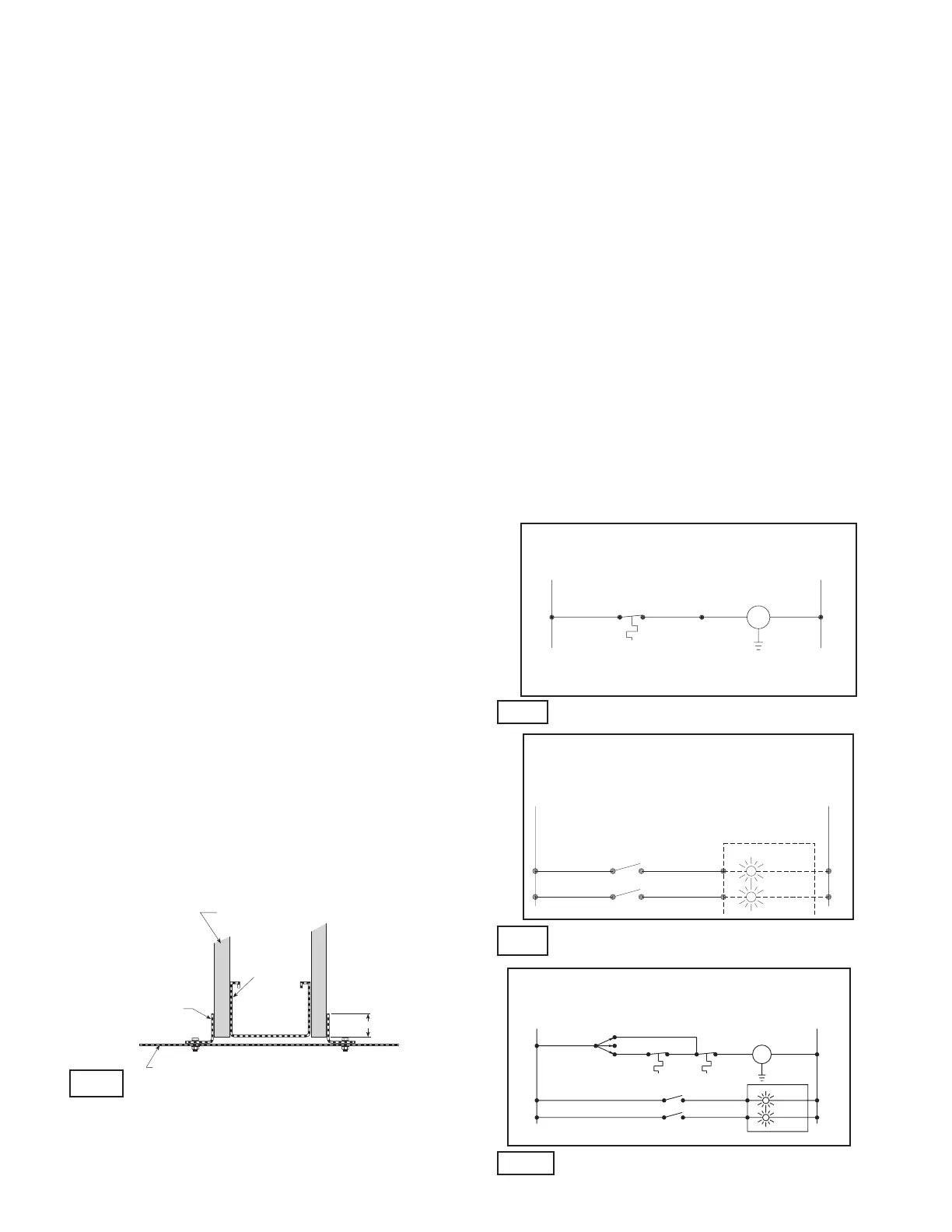

-ETAL3TUD#ONSTRUCTION

7OODEN3TUD#ONSTRUCTION

)NWOODSTUDCONSTRUCTION

GYPSUMWALLBOARDMUSTCOVER

ALLWOODSTUDSURFACES

'YPSUM 7A LLBOARD

3TUDOR2UNNER

2ETAINING

!NGLE

IN-IN

$AMPER

3LEEVE

)NMETALSTUDCONSTRUCTION

EXPOSEDSTEELSURFACESNEED

NOTBECOVERFEXJUIHZQTVN

WALLBOARD

'YPSUM 7ALLBOARD

3TUDOR2UNNER

2ETAINING

!NGLE

IN-IN

$AMPER

3LEEVE

L1

DAMPER

INDICATOR

LIGHTS

L2

CLOSED POSITION OF THE DAMPER.

A BLUE MARKER INDICATE THE

THE SWITCH WIRES WRAPPED WITH

NOTE:

YELLOW

ELECTRICAL CAPACITY = 10AMP @ 120 / 240 VAC

YELLOW

YELLOW

YELLOW

NO

NO

S2

S1

BY OTHERS

OCI Wiring

Fig. 6

Fig. 7

L1

M

L2

ELECTRIC DAMPER

ACTUATOR OR PNEUMATIC

SOLENOID VALV E

PRIMARY TEMP

SENSOR

ELECTRICAL CAPACITY = 10 AMP @ 120 / 240

VA

C

BLACK

ORANGE

P

NC

BLACK

WHITE/RED

RRL Wiring

Fig. 9

7. CONNECTION AND OPERATION OF TEMPERATURE

RESPONSE DEVICES (continued)

TOR - The TOR (temperature override device) option

incorporates two thermostats with fixed settings (usually 165°F

and 350°F). The primary sensor (the sensor with the lower

temperature setting) can be bypassed by an external electrical

signal allowing the damper to reopen until the temperature

reaches the setting of the secondary sensor (the sensor with

the higher temperature setting). See Figure 8.

When the temperature of the secondary sensor is exceeded the

damper closes and remains closed thereafter.

The TOR assembly also contains a single pole, double throw

switch used to indicate damper blade position. The switch

provides a positive open or closed signal when used in

conjunction with remote indicator lights. See Fig. 8 for wiring of

the TOR thermostats and indicator switches.

If either the TOR or the RRL is ordered with a pneumatic

actuator, an EP switch is required with an appropriate electric

power circuit to allow the electric thermostat to control the

pneumatic actuator.

PRV - The PRV (pneumatic relief valve) option is heat

responsive device used with pneumatic actuators. This can

be used in place of EP switch where a RRL is used. The PRV

activates when temperature in excess of the temperature of the

fusible link are detected. When the fusible link melts, air from

the actuator is exhausted to close the dampers. Pneumatic

actuators are to be piped per local code.

8. Recommended Preparation of Openings in Wood

and Metal Stud Walls

• Frame wall openings as shown below. (see Fig. 9 & 10)

• Double vertical studs are not required for openings 36 in. x

36 in. or smaller.

• Gypsum wall board must be fastened 12 in. on center to

all stud and runner flanges surrounding opening.

(see Fig. 11)

• All construction and fasteners must meet the requirements

of the appropriate wall design (See UL Fire Resistance

Directory) and/or local codes.

Loading...

Loading...