Symptom Possible Cause Corrective Action

Frame is ‘racked’ causing blades to Adjust frame such that it is square

bind on jamb seals and plumb

Actuator linkage loose Close damper, disconnect power, adjust

and tighten linkage

Defective motor Replace

Screws in damper linkage Locate screws and remove

Actuator linkage hitting wall or floor Damper installed too far into wall. Move

out to line designated on damper label.

Contaminants on damper Clean with a non-oil-based solvent

(see Damper Maintenance)

Copyright © 2005 Greenheck Fan Corporation

IOM 461336 FSD Rev. 8 May 2005

Damper does not

fully open and/or

fully close

Damper does not

operate

RRL or TOR sensor

tripped

Heat

No power supplied to the actuator

Push reset button located on backside

of RRL or TOR.

Damper Trouble Shooting

The following is a possible cause and correction list for common concerns with the dampers.

Damper Maintenance

Dampers do not typically require maintenance as long as they are kept dry and clean. If cleaning is necessary,

use mild detergents or solvents. If lubrication is desired for components such as axle bearings, jackshaft

bearings and jamb seals, do not use oil-based lubricants or any other lubricants that attract contaminants such

as dust.

Dampers and their actuator(s) must be maintained, cycled, and tested a minimum of every six months and in

accordance with:

• The latest editions of NFPA 90A, 92A, UL864, and local codes.

• Actuator manufacturer recommendations.

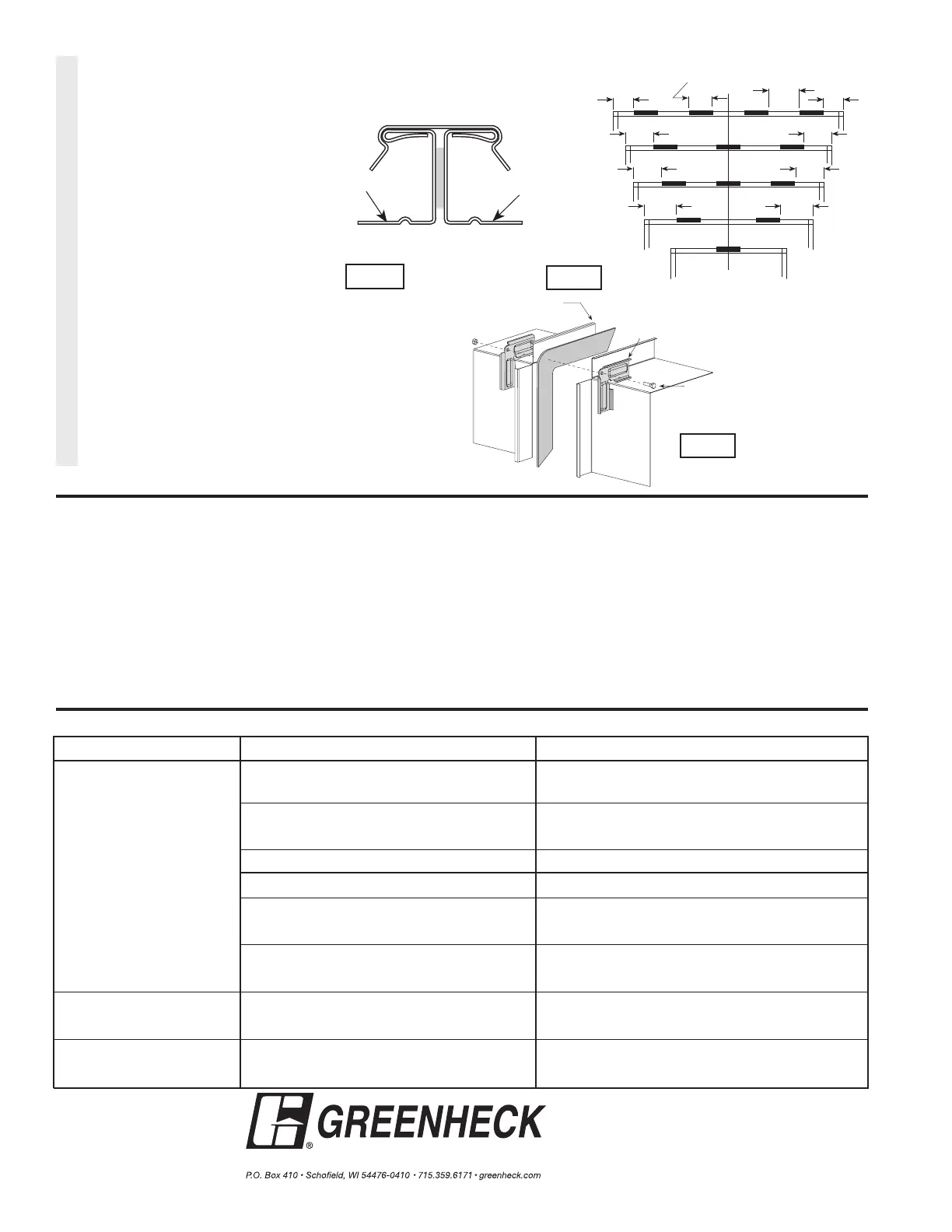

$UCT

3LEEVE

IN

3TD#LIP

,ENGTH

#

,

$UCT

IN$UCT

2EQD

IN$UCT

2EQD

IN$UCT

2EQD

IN$UCT

2EQD

IN$UCT

3MALLER

2EQD

#LIP3PACING

4YPICAL4$#4$&JOINT

IN IN

IN

ININ

IN IN

ININ

Proprietary Flange System

Breakaway Connections

(TDC by Lockformer, TDF by Engle)

TDC and TDF systems are approved

as breakaway connections when

installed as described in the TDC or

TDF addendum to the SMACNA Duct

Construction. Standard 6 in. metal clips

may be used with spacing as shown in

diagram. 3/8 in. metal bolts and nuts

may be used to fasten together corner

pieces (see Figure17).

Fig. 16

Fig. 15

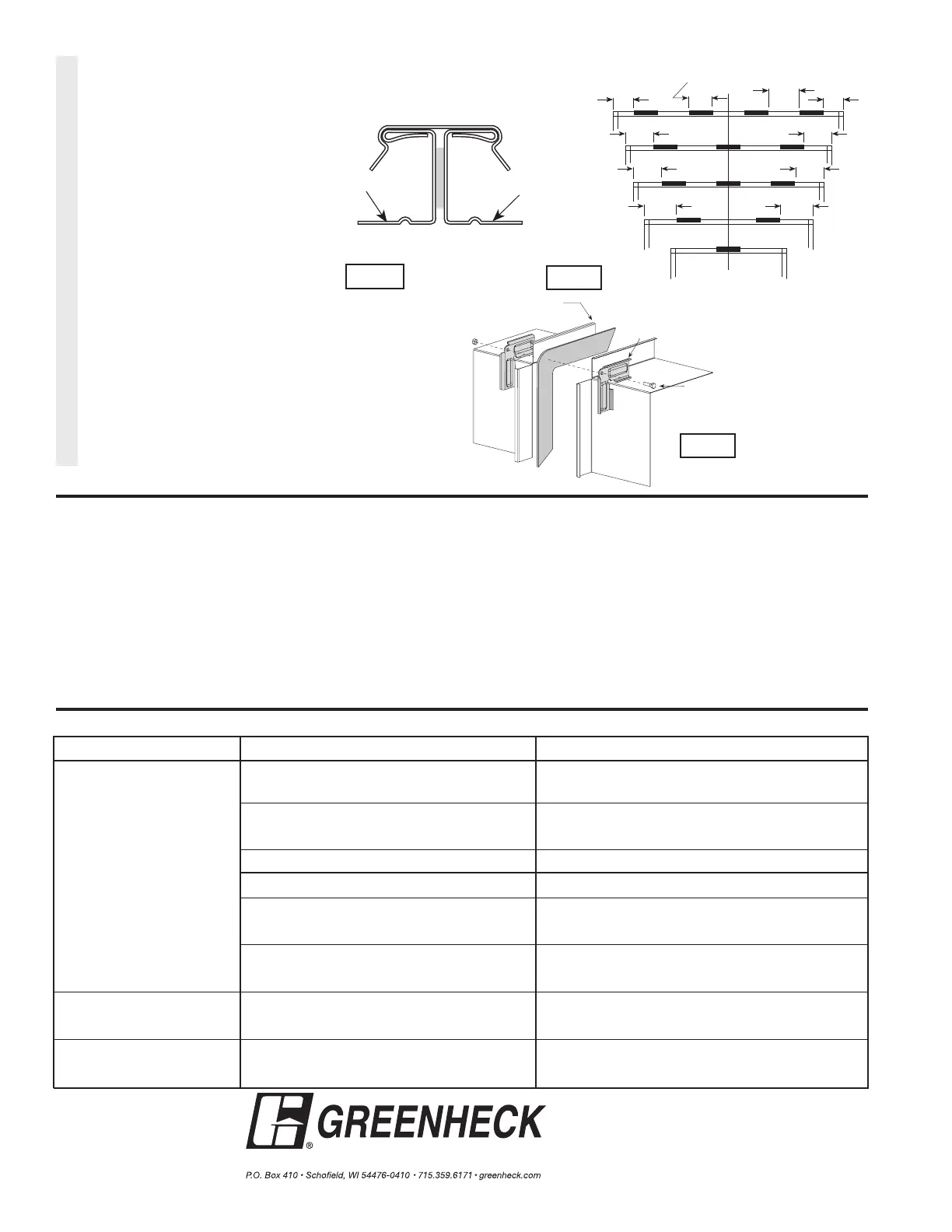

Proprietary

$UCT%ND

&LANGE

#ORNER0IECE

INBOLT

OPTIONAL

Fig. 17

Loading...

Loading...