22

15.2 ENGINEMAINTENANCE

IMPORTANT:checktheengineperiodically,keeptheairlter

cleanandtheengineoillevel.

Manual access to the engine coMpartMent

To access the engine if the machine breaks down, engage the parking

brake, switch off the engine, hold down the grass catcher tipping lever and

simultaneously push the grass catcher towards the rear of the machine.

The grass catcher will pivot allowing access to the engine compartment.

air filter

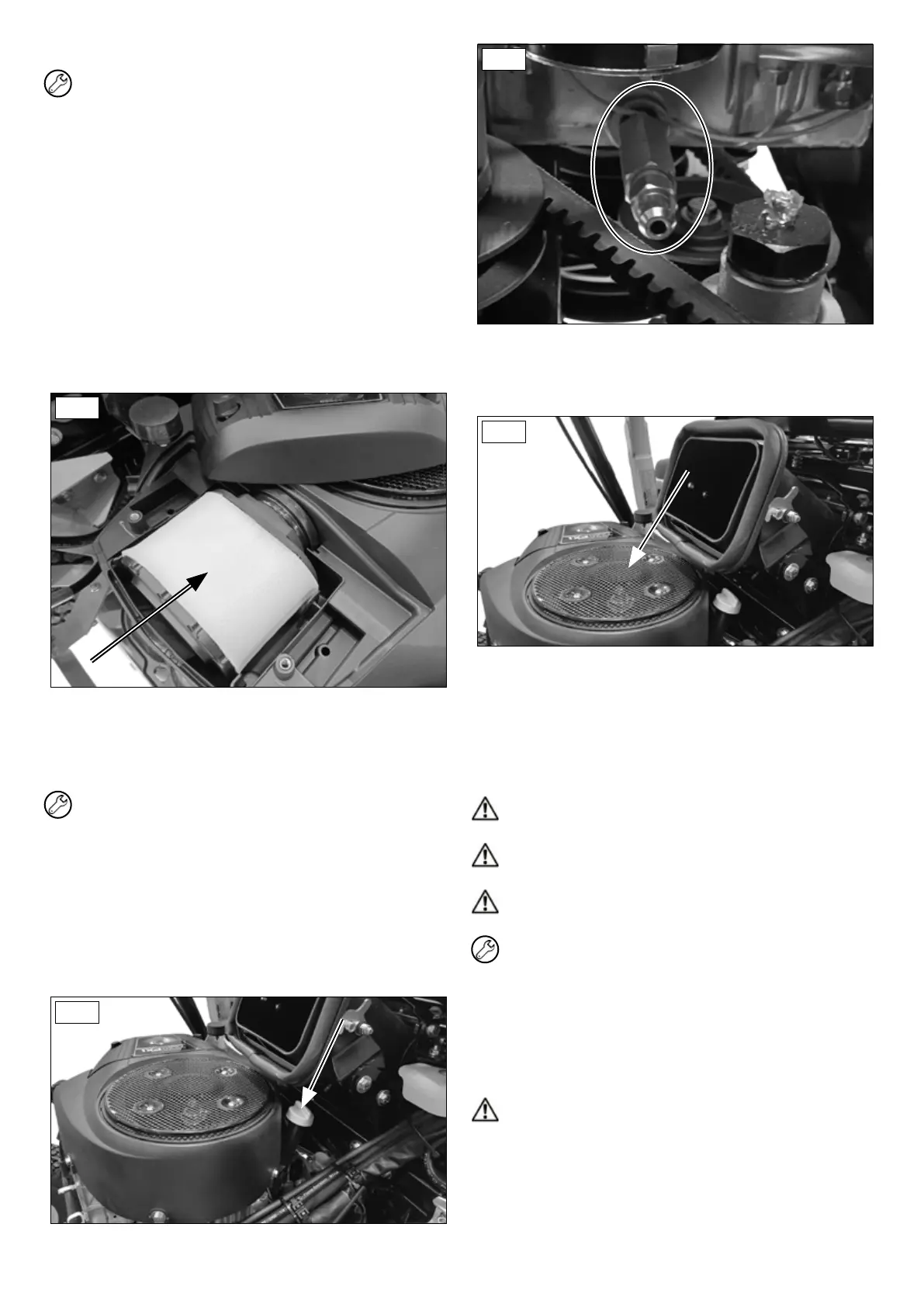

Checkandcleantheairlter(g.38)every4hours.Formaintenance

intervals and procedures follow the rules contained in this manual (ref.

18. Maintenance schedule); for further details consult the engine manual.

Ifworkinginverydustyenvironments,itisadvisabletocleantheairlter

every2hoursorasneeded.Iftheltrationelementisdamaged,replace

it.

Fig. 38

engine oil

For lubrication intervals and procedures follow the rules contained in this

manual (ref. 18. Maintenance schedule); for further details consult the

engine manual.

IMPORTANT:itisessentialtochangetheoilandoillterafter

therst20hoursofoperation.

Then change the oil every 100 hours or every year. For the engine, use

SAE 30 oil in a quantity of 1.9 litres.

Tocheckthe oil level,use the oildipstick (g. 39)when the engineis

cold. To drain all the oil from the engine, connect a rubber hose to the end

oftheoildrainplug(g.40),thenloosentheendpartwhileholdingthe

xedpartofthepluginplacewithacounterspanner;draintheoilintoa

container.

Protect the belts from coming into contact with the oil.

Fig. 39

Fig. 40

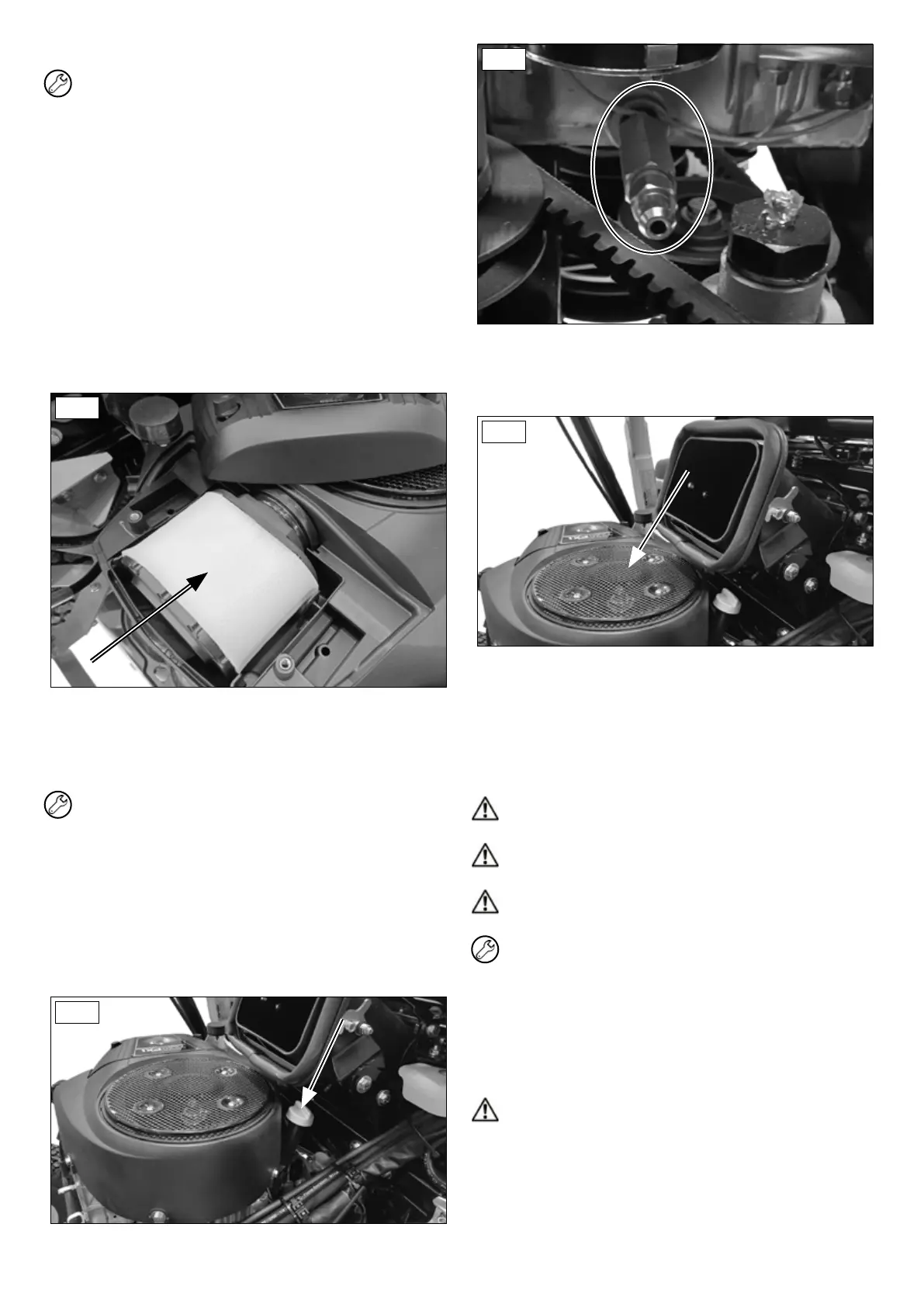

engine cooling systeM

Inordernottoimpairtheairow,checkthattheprotectivegrilleonthetop

oftheengine(g.41)isalwayswellclean.

Fig. 41

15.3 BATTERYMAINTENANCE

The battery does not require any special maintenance.

Itissufcienttocheckthatthevoltageisnotlowerthan12.5Voltsand

recharge it if necessary.

To recharge the battery it is necessary to disconnect the cables and

remove the battery from the machine (ref. 16.7 Battery Replacement).

CAUTION:charginghastobecarriedoutinadryandventilated

area,freeofsparksandheatsources.

CAUTION: do not reverse the polarity of the battery, and be

carefulnottocauseashortcircuit.

CAUTION: the gases released by the battery are explosive,

keepitawayfromamesorsparks.

IMPORTANT:donotattempttostartthemachineifthebattery

is not correctly secured and connected: the alternator and the

control unit could be damaged.

It is recommended to periodically check the good condition of the positive

(red) electrical cables connecting the battery with the fuses, starter motor

and alternator, and always in the event of a workshop service. Check that

they are secure, not marked by wear, and not in contact with sharp edges

or sharp parts of the machine.

CAUTION:damagetoelectricalcablescancauseshortcircuits

andrehazards.

Loading...

Loading...