24

C

B

A

Fig. 48

9. Bleed the hydrostatic transmission as follows:

- Place the machine safely on stands with the front wheels raised

offtheground,makesurethebypassvalveisengaged(g.46);

- Start the engine, wait a few minutes and make a few gear

changes (forwards and backwards) using the travel pedal;

- Disengage the bypass valve by pulling it towards the outside of

themachine(g.47)andcarryoutafewgearchanges(forwards

and backwards) using the travel pedal;

10. Place the machine back on the ground and check its

travel and halting; in the event of reduced performance,

loss of power or noise, repeat bleeding (point 9);

Visuallychecktheoillevelintheexpansiontank(g.43).Whenthe

engine is cold, the oil level should be approximately 1 cm from the

bottom of the expansion tank.

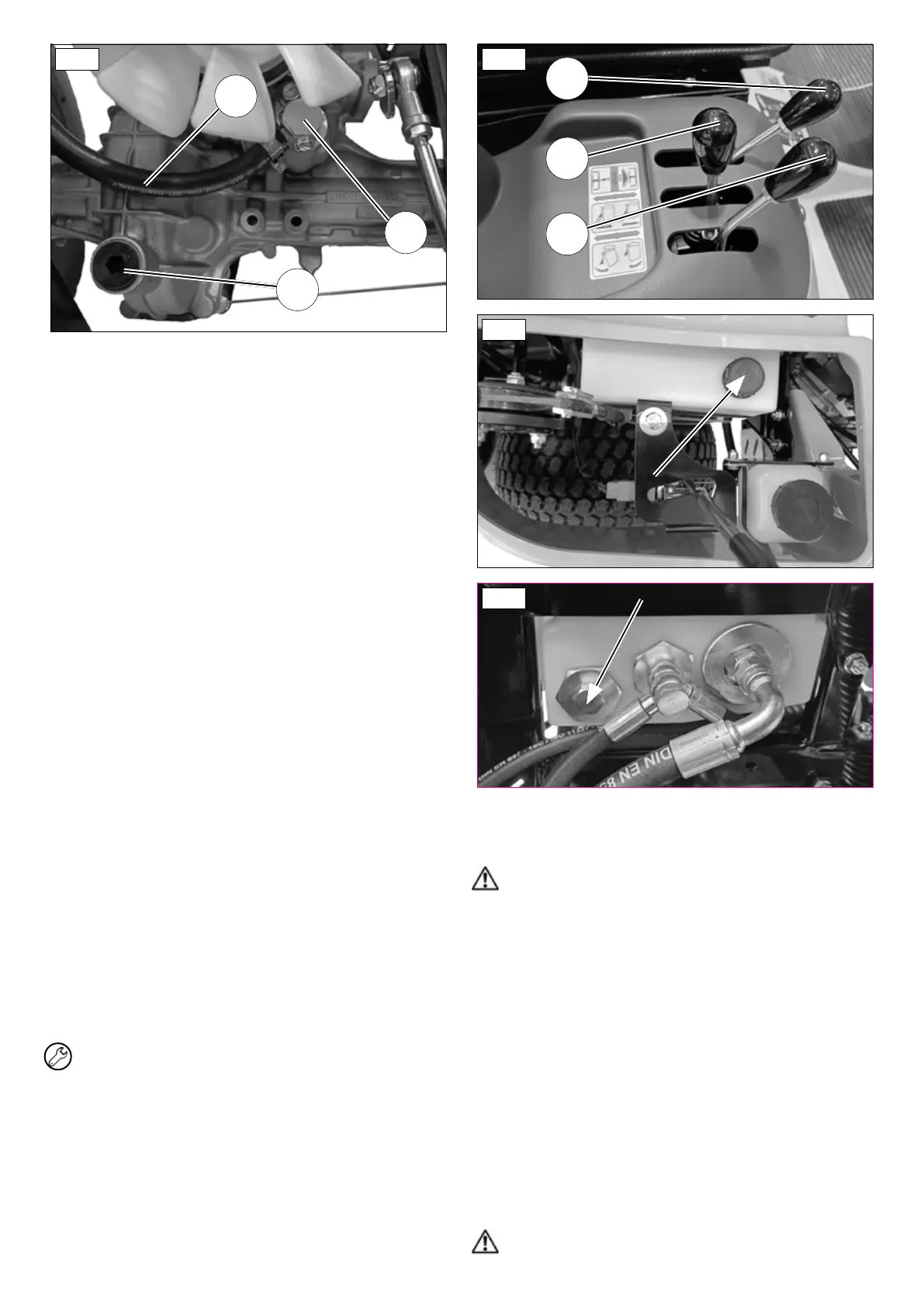

16.3 HYDRAULICSYSTEMMAINTENANCE

hydraulic services distributor

Thehydraulicleverdistributor(g.49)operatesatamaximumoperating

pressure of approximately 140 bar.

Lever2makesthecuttingdeckoatingorcanliftit.

Lever 3 lifts / lowers the grass catcher.

Lever 4 tips the grass catcher for unloading.

Check the level in the hydraulic oil tank periodically, when the oil is cold.

Tocheckthelevelortotopuptheoil,pullouttheoillevelcap(g.50).

Check the level by using the dipstick of the oil tank cap: the level must

be between the two notches at the end of the dipstick. Check the level

inserting the cap on and off completely each time. To remove the oil,

loosenthedrainplugonthesideofthetank(g.51).

Changethehydraulicoilthersttimeafter100hours,thenevery400

hours. It is not necessary to bleed the hydraulic system.

The oil must be changed before 100 hours if:

• The oil is dark in colour;

• The oil is off-white in colour (oil is contaminated with water);

• There are black residues (partial deterioration of the oil).

UsehydraulicoilOSO48inaquantityof3.8litresincludingllingthe

circuit.

IMPORTANT:payparticularattentiontoanycontaminationthat

couldenterthecircuitandcauseseriousdamagetothemachine.

2

3

4

Fig. 49

Fig. 50

Fig. 51

16.4 CUTTINGDECKMAINTENANCEAND

COMPLETEDISASSEMBLY

CAUTION:carryouttheoperationwiththeengineswitchedoff

andthebrakeapplied.

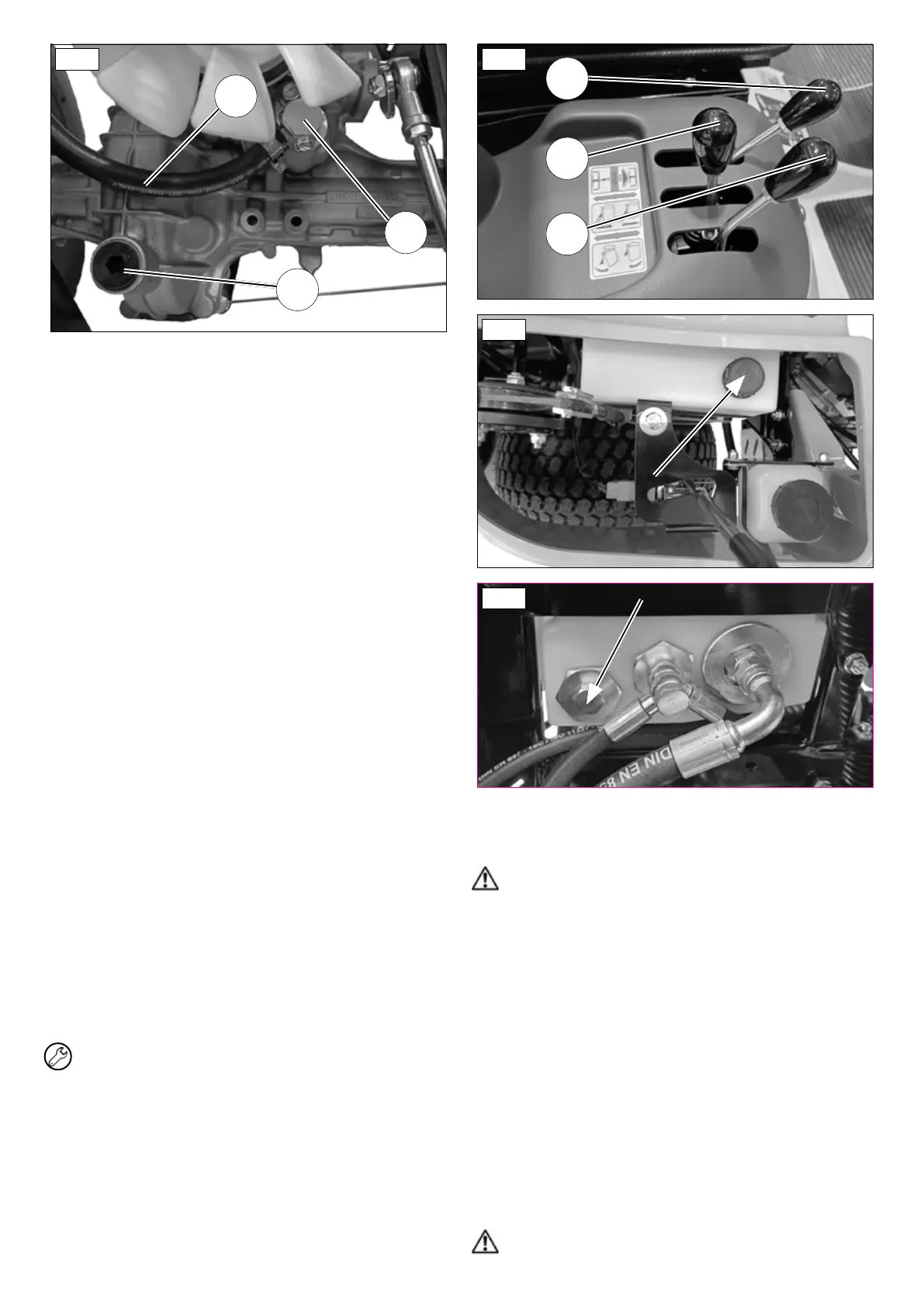

Proceed as follows to remove the cutting deck:

1. Remove the loading chute;

2. Lower the cutting deck bringing the distributor lever to the FLOAT

position(g.49/2)andlowerthecuttingheightcompletely;

3. Remove the guard above the cutting deck by unscrewing the two

knobs(g.52/A);

4. Removethecotterpin(g.53/B);

5. Loosen the belt by turning the lever on the tensioner anti-clockwise

(g.53/C);

6. Remove the PTO belt;

7. Unfasten the connector of the electric actuator for the height

adjustment(g.54/D);

8. Movetheframe/platequickcouplingleverbackwards(g.54/E);

9. Remove the cutting deck from the machine and place it vertically

onitssupports(g.55).

To reassemble the plate follow the procedure in reverse order.

To reassemble the cutting deck follow the procedure in reverse order.

CAUTION:whenrettingtheplate,checkthattheloadingchute

Loading...

Loading...