57

Specications are subject to change without prior notication December 2019

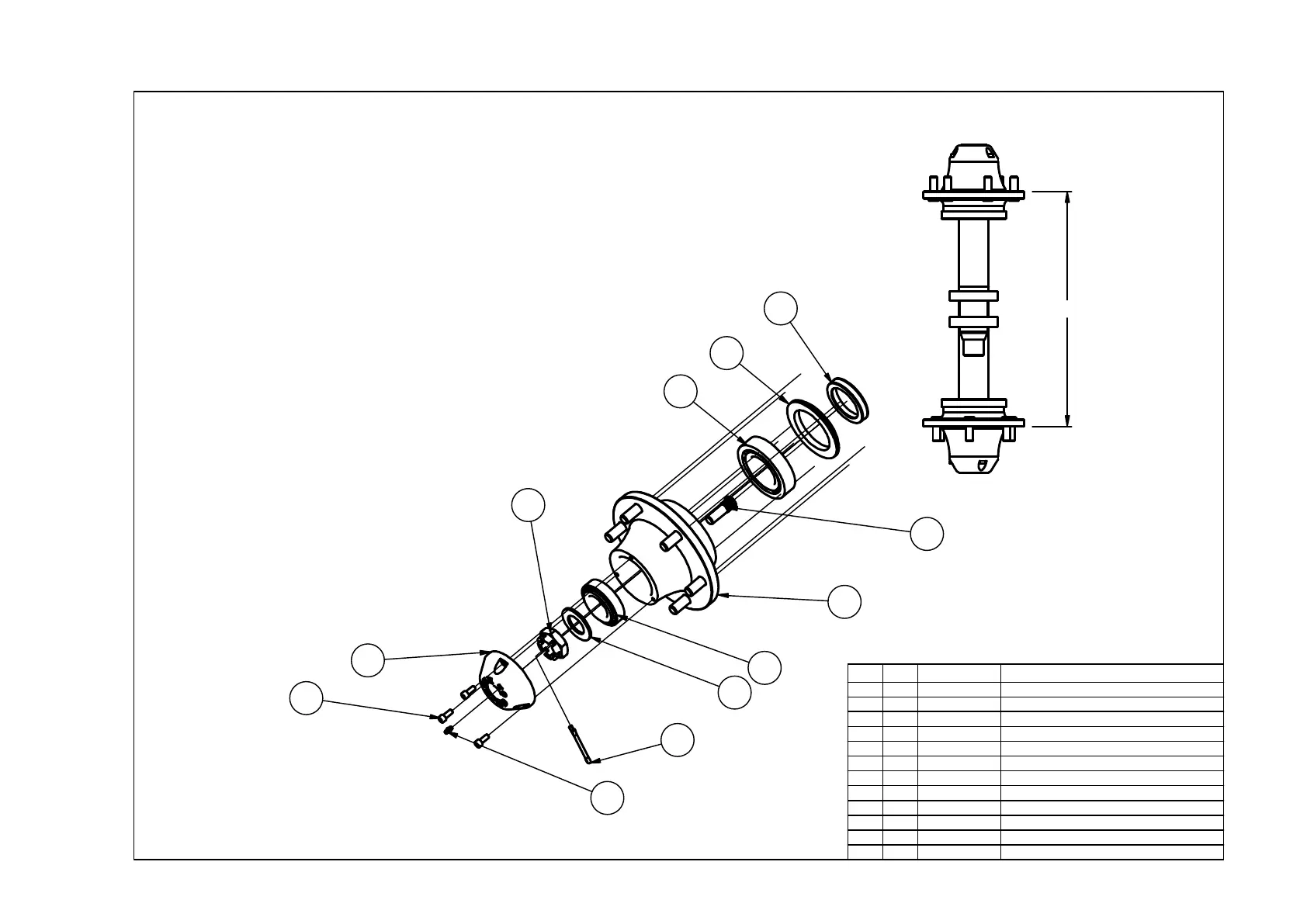

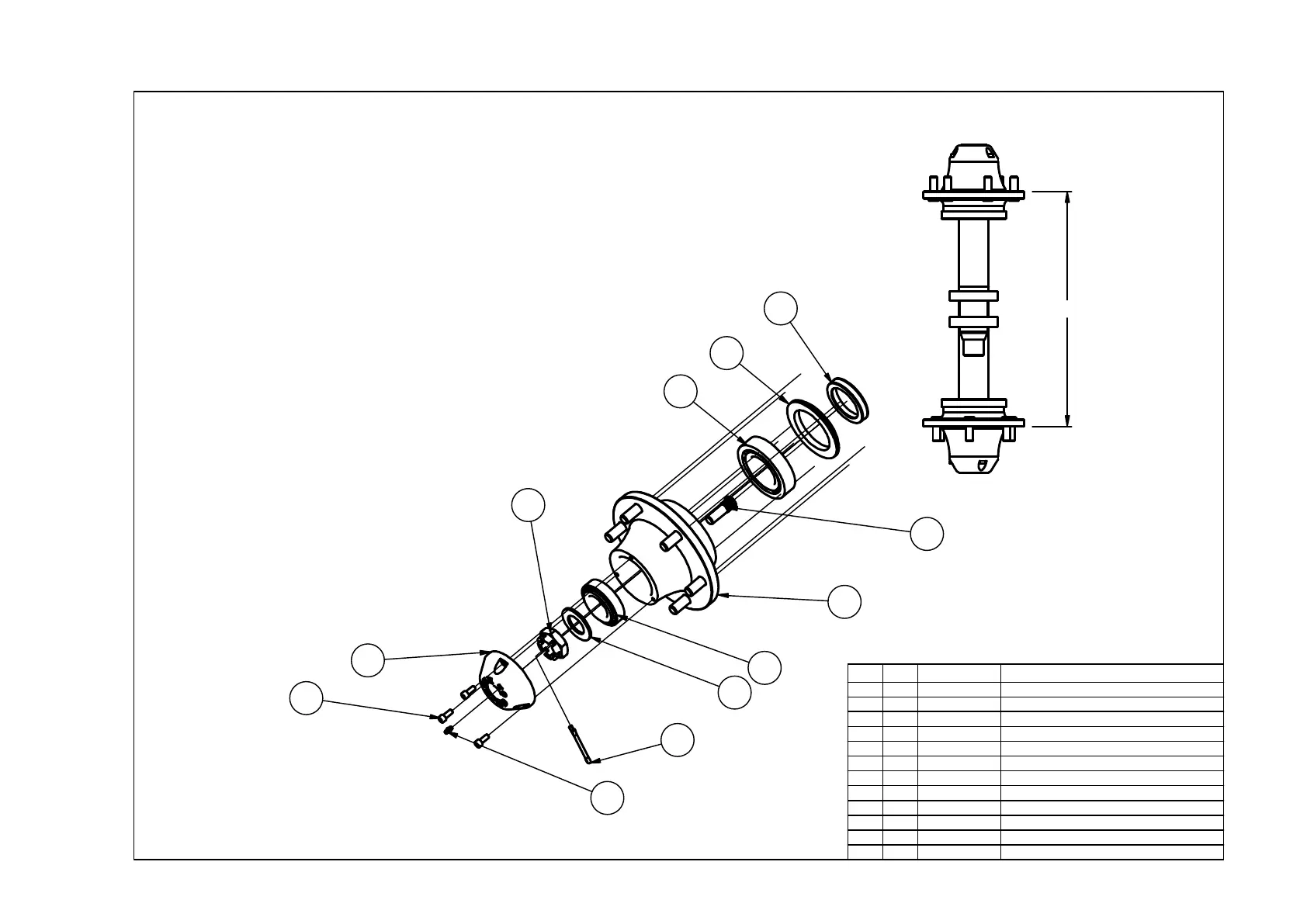

DESCRIPTIONPART NOQTYPOS

BEARING - H70 INNER (32213)BBMAA00021

BEARING FOR H70 OUTER (32210)BCMAA00022

H70 TRIPPLE LIP SEALBNRBA01023

WHEEL STUD 18 X 55 (PC10.9-12.9)FDBJA001124

1 1/2"UNF CASTELLATED NUT FFCUA0002

5

8 X 20 SOCKET HEAD CAP SCREWFJBEA02066

Split Pin 6 X 80FKCFA080

27

WASHER 41 X 70 X 4FMAUKP0028

H70 ROCKER W/ASSY PIVOT RIPPERGNBXN00119

SEAL SPACER

MFRNA015210

H70 HUBWJMAA000211

H70 CAPWKMBA000212

H70 HUB ASSEMBLY

L:\Inventor\Parts\WM-\WMMDA450.IDW

9

3

1

4

10

2

8

5

7

11

6

11

WMMDA450

To assemble and adjust the setting of this

hub:

NOTE: CLEAN THREAD BEFORE ASSEMBLING, IF

YOU ARE ASSEMBLING A NEW AXLE USING 1-

2

"

UNF DIE NUT, CLEAN ALL OTHER COMPONENTS.

Step 1: Clean and prime the seal #3 and seal ring

#9 Fit seal to seal ring using Loctite 480, allow to

dry before proceeding.

Step 2: Fit bearing cups #1 and #2 into the

hub, place bearing cone #1 into the hub.

Step 3: Fit the se

al and seal ring to axle, ensure

this does not rotate on axle, use loctite 680 if

required.

Step 4: Fit the hub to the axle, then fit the

bearing cone #1, washer #8, and nut #5.

Step 5: Tighten the nut while turning the hub.

When there is a tight bind on the bearing, the

parts are seated correctly, approx 150ft/lbs.

Step 6: Back the nut off 1/6 to 1/4 of a turn or

sufficiently to allow .005mm to .02mm end

play.

Note: Failure to back off adjusting nut could cause

bearing to run hot and fail.

Step 7: Insert the split pin #7 as shown, trim the

straight leg, bend the other over the axle end.

Step 8: Fit the cap #11 using loctite 515 flange

sealant on the faces, and tighten the 3 M8 #6 cap

screws 16nm(12ft/lbs).

Step 9: Grease with a grease gun using CASTROL

BTX

or similar until grease is visible through rear sea

l.

592

Loading...

Loading...