"''"

BdYZa<%+)%MB[\#H^cXZ&$%.

I]ZWaVYZ\j^YZhegdk^YZh^YZ"id"h^YZhjeedgiid

]Zae `ZZe i]Z WaVYZ higV^\]i l]^aZ Xjii^c\# I]Z

WaVYZ\j^YZhVgZYZh^\cZYidWZVY_jhiZY^cild

lVnh·[dglVgY$WVX`lVgYVcYh^YZ"id"h^YZ#

To adjust the upper and lower blade guides:

1. BV`ZhjgZi]ZWaVYZ^higVX`^c\egdeZganVcY

i]Vi^i^hXdggZXianiZch^dcZY#

2. 9>H8DCC:8I76C9H6L;GDBEDL:G

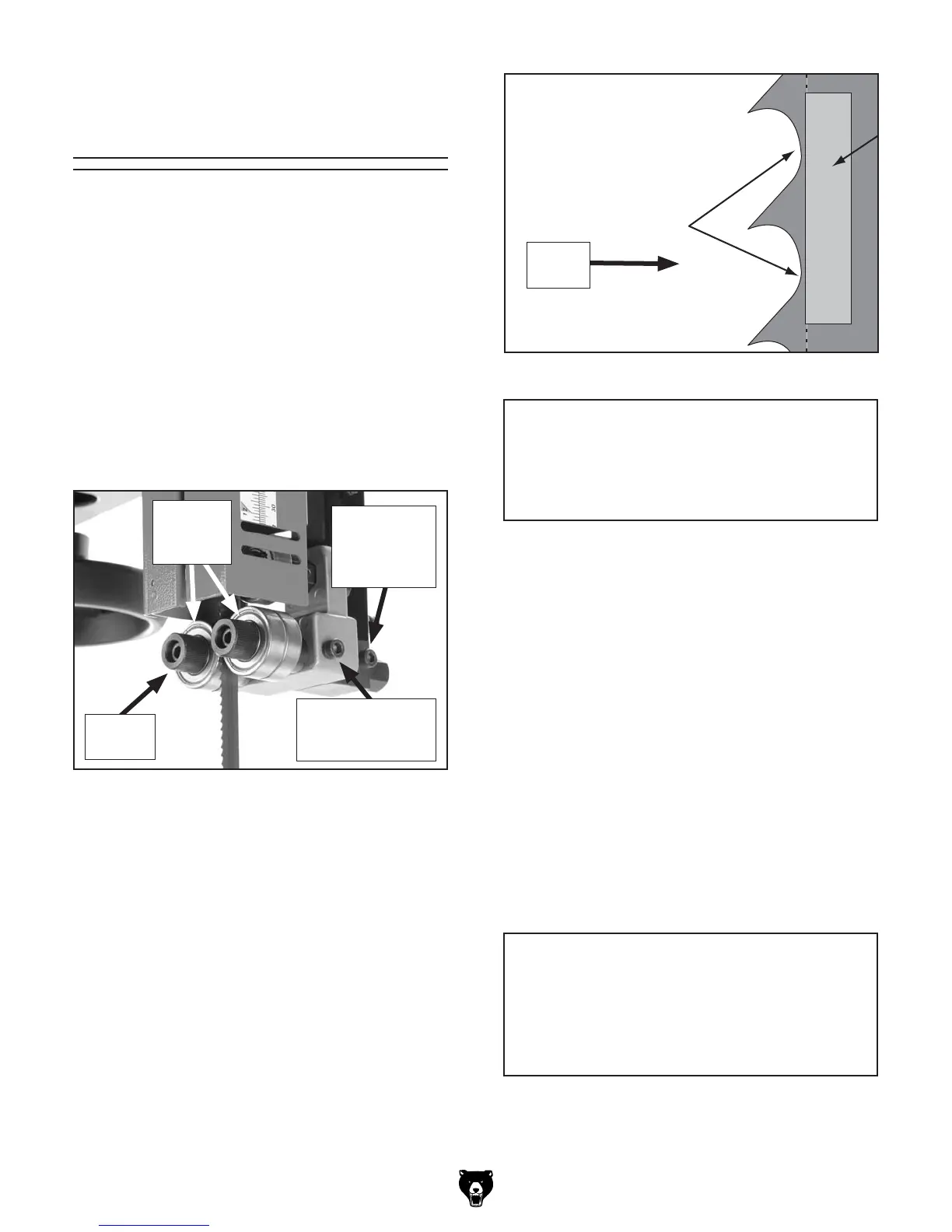

3. ;Vb^a^Vg^oZ ndjghZa[ l^i] i]Z jeeZg WaVYZ

\j^YZXdcigdahh]dlc^cFigure 21#

Adjusting Blade

Guides

Figure 21.7aVYZ\j^YZXdcigdah#

AViZgVa

6Y_jhibZci

GdY8Ve

HXgZl

@cjgaZY

@cdW

7aVYZ

<j^YZ

7ZVg^c\h

7ZVg^c\GdiVi^dc

6Y_jhibZci8Ve

HXgZl

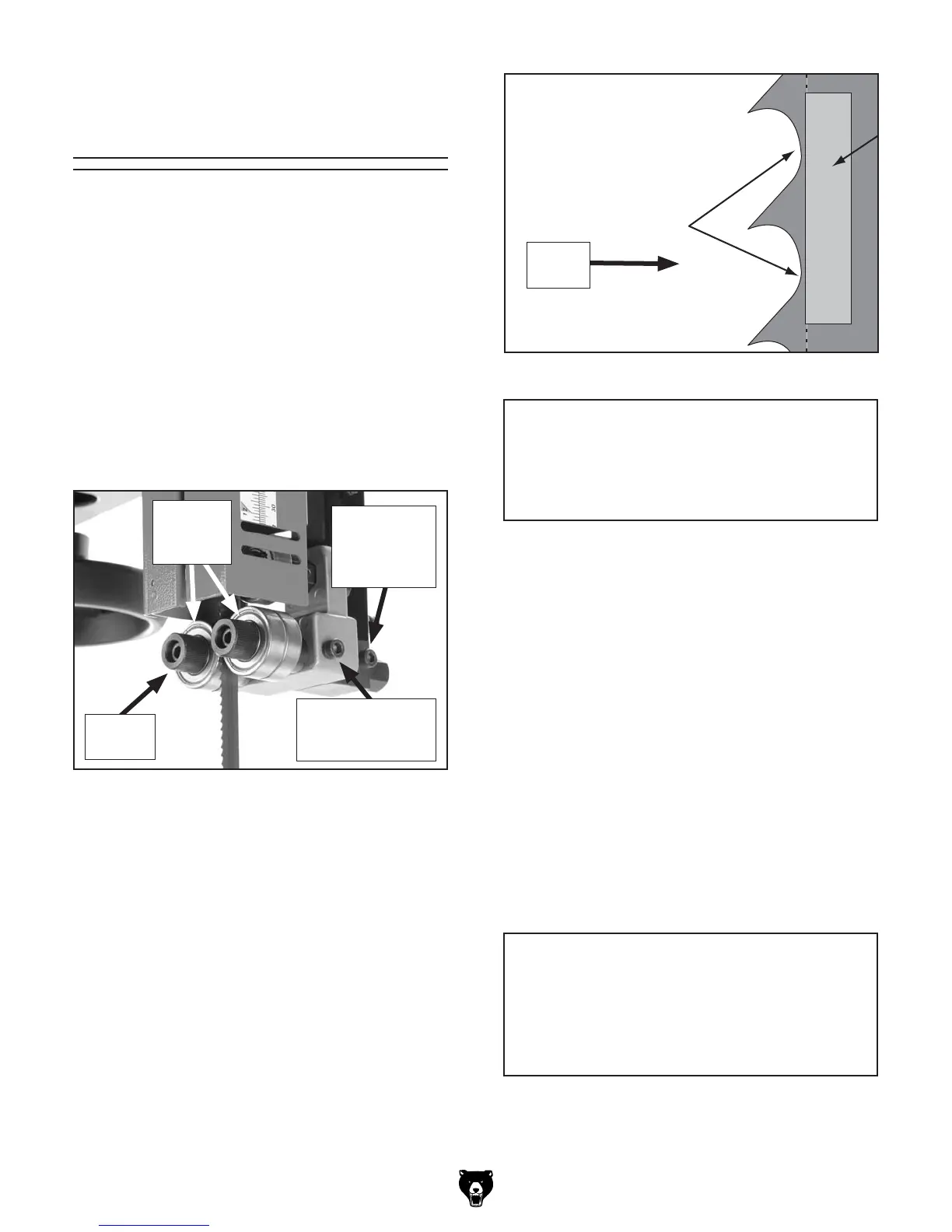

4. AddhZc i]Z XVe hXgZl dc i]ZaViZgVaVY_jhi"

bZci gdY VcY VY_jhi i]Z WaVYZ \j^YZh jci^a

i]ZZY\Zhd[i]ZWZVg^c\hVgZ

&

$&+WZ]^cYi]Z

WaVYZ\jaaZih!Vh^aajhigViZY^cFigure 22#

Note: The

1

/16" spacing is ideal, although with

larger blades it may not be possible. In such

cases, adjust the guide bearings as far for-

ward as possible to the blade gullets, and still

maintain the proper support bearing spacing

adjustment.

7aVYZ

<jaaZih

Figure 22.AViZgVaVY_jhibZcid[WaVYZ\j^YZh#

7aVYZ

<jaaZi

NOTICE

Make sure that the blade teeth will not con-

tact the guide bearings when the blade is

against the rear support bearing during the

cut or the blade teeth will be ruined.

5. I^\]iZci]ZXVehXgZl dc i]ZaViZgVaVY_jhi"

bZcigdY#

6. AddhZc i]Z WZVg^c\ gdiVi^dc VY_jhibZci XVe

hXgZlh#

7. JhZi]Z`cjgaZY`cdWid gdiViZi]ZWZVg^c\h

%#%%)VlVn[gdbi]ZWaVYZ#

Note: 0.004" is approximately the thickness

of a dollar bill.

8. I^\]iZci]ZXVehXgZlidadX`i]ZWaVYZ\j^YZ

WZVg^c\h^cedh^i^dc#

9. GZeZVi i]^h egdXZYjgZ [dg i]Z adlZg \j^YZh#

6aai]dj\]i]ZadlZg\j^YZhVgZhZijeVa^iiaZ

Y^[[ZgZcian!i]ZXdcXZei^hi]ZhVbZ#

NOTICE

Whenever changing a blade or adjusting ten-

sion and tracking, the upper and lower blade

support bearings and guide bearings must

be properly adjusted before cutting opera-

tions.

Loading...

Loading...