"')"

BdYZa<%+)%MB[\#H^cXZ&$%.

Adjusting Positive

Stop

6c VY_jhiVWaZ edh^i^kZ hide Vaadlh i]Z iVWaZ id

ZVh^angZijgcid.%V[iZgi^ai^c\#6[iZgVY_jhi^c\i]Z

edh^i^kZ hide id .%! i]Z ed^ciZg dc i]Z iVWaZ i^ai

hXVaZh]djaYWZVY_jhiZYidi]Z%bVg`idZchjgZ

i]Vii]ZiVWaZi^aihXVaZ^hVXXjgViZ#

To set the positive stop 90° to the blade:

1. BV`ZhjgZi]ZWaVYZ^hXdggZXianiZch^dcZYVh

YZhXg^WZY ^c i]Z Blade Tensioning ^chigjX"

i^dchdcPage 21#

2. 9>H8DCC:8I76C9H6L;GDBEDL:G

4. 8]ZX` id bV`Z hjgZ i]Z hjeedgi WZVg^c\ ^h

edh^i^dcZYY^gZXianWZ]^cYi]ZWaVYZ#

·>[i]ZhjeedgiWZVg^c\^hedh^i^dcZYY^gZXian

WZ]^cY i]Z WaVYZ!Xdci^cjZ dc idi]ZcZmi

hiZe#

·>[ i]Z hjeedgi WZVg^c\ ^h cdi edh^i^dcZY

Y^gZXianWZ]^cYi]ZWaVYZ!addhZci]Zigjc"

c^dc bdjci^c\ XVe hXgZlh VcY h]^[i i]Z

igjcc^dc VhhZbWan dkZg jci^a i]Z hjeedgi

WZVg^c\^hWZ]^cYi]ZWaVYZ#

Note: The table must be re-aligned with the

blade if the trunnion assembly is moved.

Refer to Page 25.

5. AddhZci]ZXVehXgZldci]ZhjeedgiWZVg^c\

VY_jhibZcih]V[i#

6. EaVXZ V %#%&+ [ZZaZg \Vj\Z WZilZZc i]Z

hjeedgi WZVg^c\ VcY i]Z WaVYZ! VcY jhZ

i]Z VY_jhibZci `cdW id edh^i^dc i]Z WZVg^c\

%#%&+VlVn[gdbi]ZWVX`d[i]ZWaVYZh^b^"

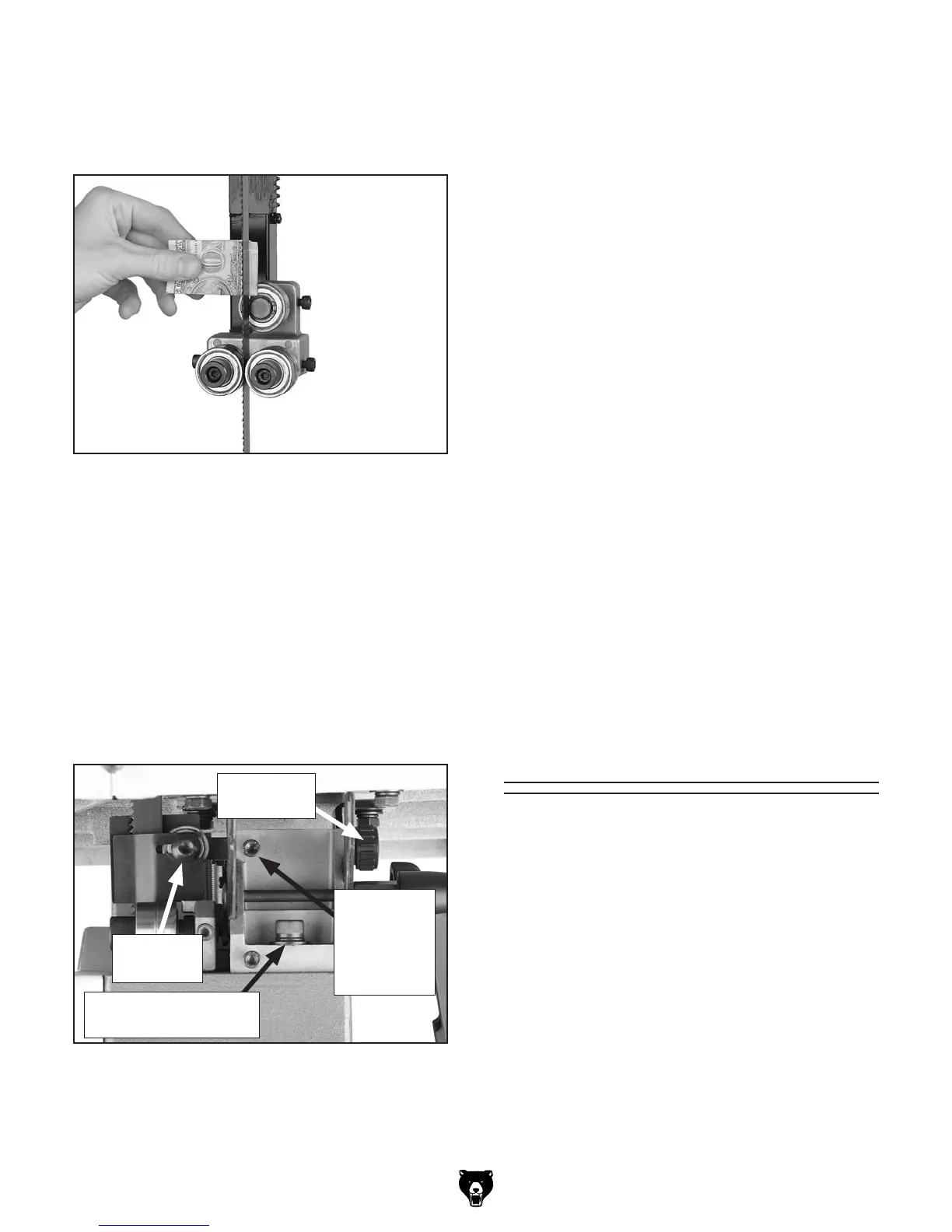

aVgidFigure 25dgjhZVYdaaVgW^aaFigure

26)^chiZVYd[V[ZZaZg\Vj\Z#

7. I^\]iZc i]Z XVe hXgZl id `ZZe i]Z hjeedgi

WZVg^c\adX`ZY^ceaVXZ#

Figure 26.9daaVgW^aa[daYZYil^XZidbV`ZVc

Veegdm^bViZ%#%&+\Vj\Z#

Note: For a quick gauge, fold a dollar bill in half

twice (four thicknesses of a dollar bill is approxi-

mately 0.016") and place it between the support

bearing and the blade as shown in Figure 26#

7. I^\]iZci]ZhjeedgiWZVg^c\XVehXgZl#

To adjust the lower support bearings:

1. BV`ZhjgZi]ZWaVYZ^higVX`^c\egdeZganVcY

i]Vi^i^hXdggZXianiZch^dcZY#

2. 9>H8DCC:8I76C9H6L;GDBEDL:G

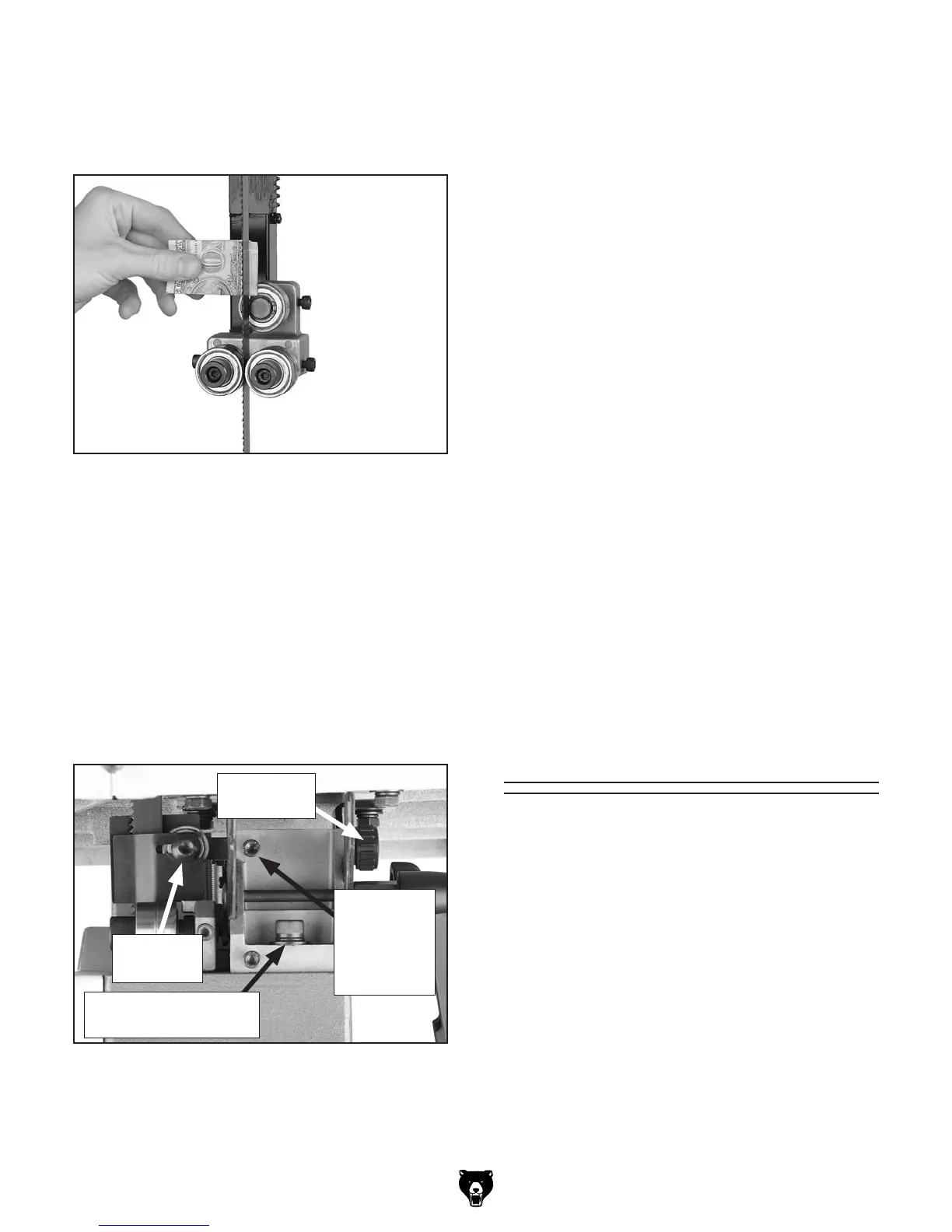

3. ;Vb^a^Vg^oZ ndjghZa[ l^i] i]Z adlZg hjeedgi

WZVg^c\Xdcigdahh]dlc^cFigure 27#

Figure 27.AdlZghjeedgiWZVg^c\Xdcigdah#

Hjeedgi

7ZVg^c\

Hjeedgi

7ZVg^c\

6Y_jhibZci

H]V[i8Ve

HXgZl

Igjcc^dcBdjci^c\

8VeHXgZl&d['

6Y_jhibZci

@cdW

Loading...

Loading...