5.2.2 Assembly

Assembly of MG 71 and MG 80, see the section on as-

sembly.

Assembly of MG 90 and MG 100, see the section on as-

sembly.

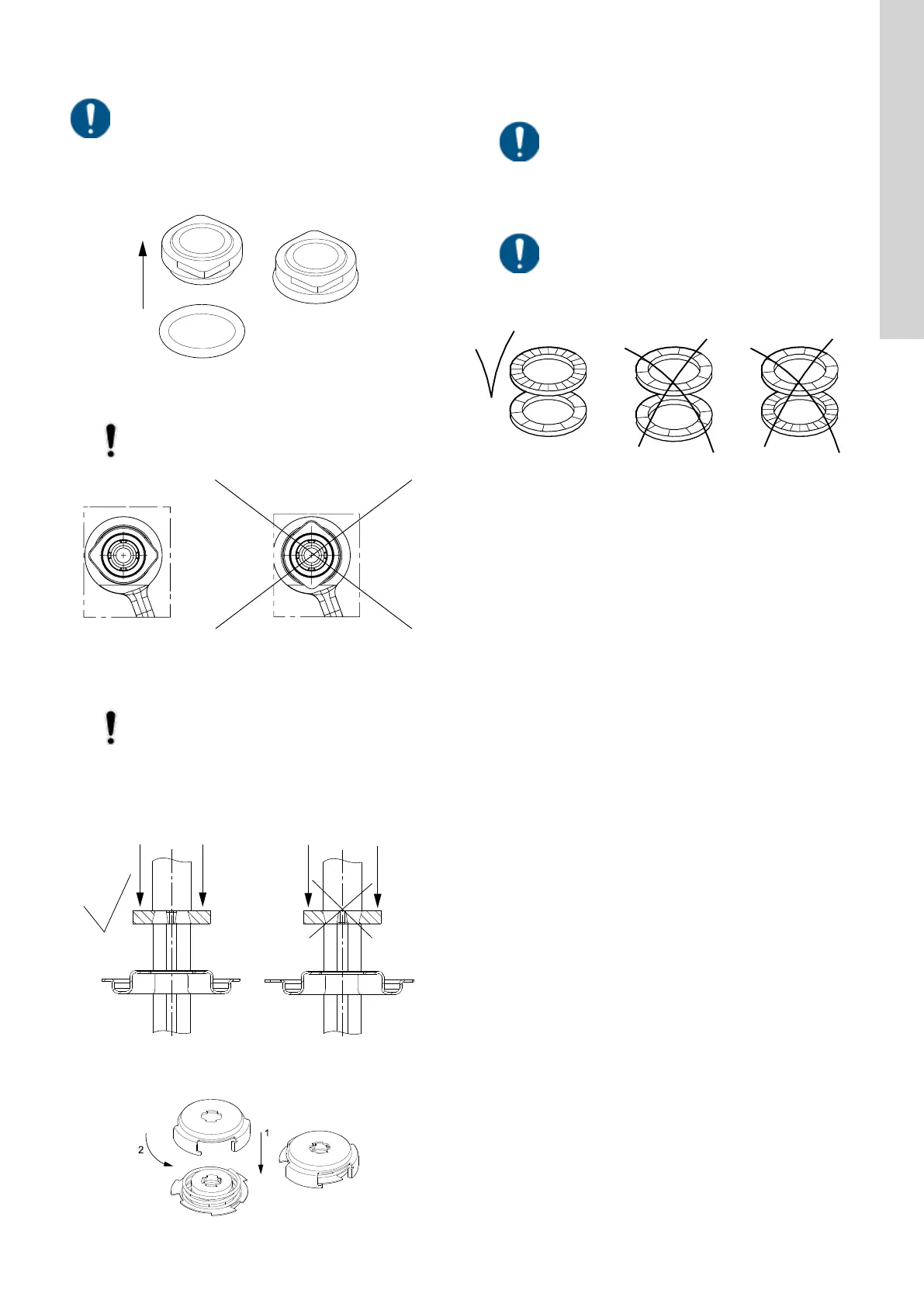

1. Fit O-ring (pos. 102) on the stationary shaft seal part. See the

figure below. For correct lubricant, see the section on tightening

torques and lubricants.

TM044322

Fitting the O-ring on the stationary shaft seal part

2. Press the stationary shaft seal part home.

Do not touch the seal face.

TM044436

Fitting the stationary shaft seal part (only SiC/SiC)

3. Fit the rotating shaft seal part (pos. 104) so that the seal face

touches the stationary part.

Do not touch the seal face.

4. Fit O-ring (pos. 107) into the rotating shaft seal part (pos. 104).

For correct lubricant, see the section on tightening torques and

lubricants.

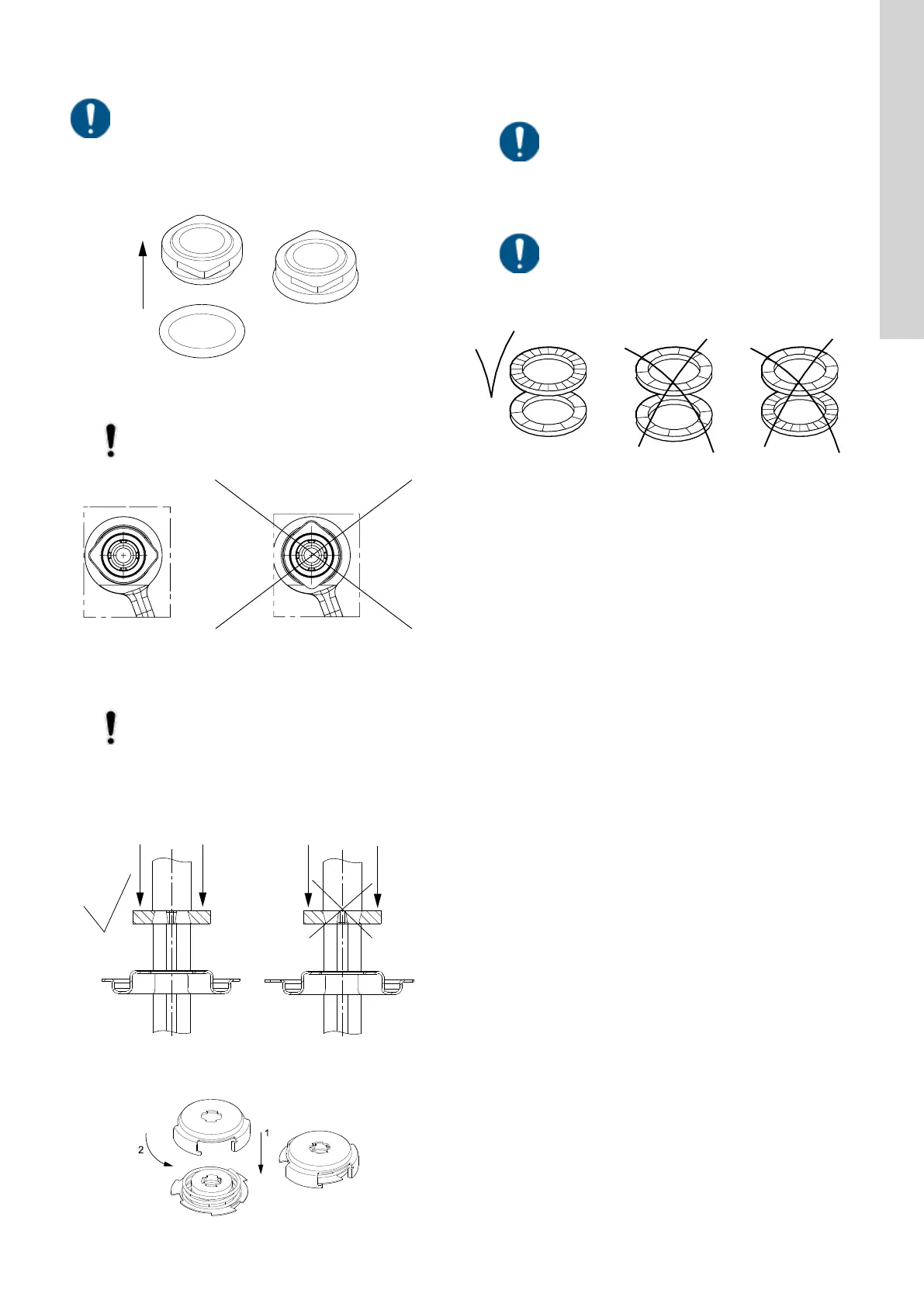

5. Fit retainer (pos. 111) and stop ring (pos. 111a).

TM044325

Fitting the stop ring

6. Fit spring (pos. 108) and driver (pos. 112).

TM044326

Fitting the spring and driver

7. Fit impeller (pos. 49), spacing pipe (pos. 64), gasket (pos. 139b)

and chamber plate (pos. 4f).

8. Continue the assembly until chamber for bearing (pos. 4a).

Step 8 applies only to pumps with eight stages.

9. Fit chamber for bearing (pos. 4a), short spacing pipe (pos. 64a),

gasket (pos. 139b) and bearing ring (pos. 47a). See the section

on order of assembly for chambers and impellers.

Step 9 applies only to pumps with eight stages.

10. Fit impeller (pos. 49), clamp (pos. 64c), washers (pos. 66) and

nut (pos. 67).

TM021057

Correct fitting of washers

11. Hold clamp (pos. 64c), and tighten nut (pos. 67). See the

section on tightening torques and lubricants.

12. Fit chamber (pos. 4e) and gasket (pos. 139b).

13. Fit inlet part (pos. 6).

14. Fit and cross-tighten staybolts (pos. 26). See the section on

tightening torques and lubricants.

Related information

3. Tightening torques and lubricants

5.6.2 Assembly

5.7.2 Assembly

8.1 Key for CM 1, 3, 5

11

English (GB)

Loading...

Loading...