5.6 MG 71 and MG 80 motors

5.6.1 Dismantling

1. Remove screws (pos. 152).

2. Remove fan cover (pos. 151).

3. Remove fan (pos. 156) and seal ring (pos. 159a).

4. Remove screws (pos. 181).

5. Remove motor flange (pos. 156b) and gasket (pos. 157a).

6. Remove diverting disc (pos. 79), O-ring (pos. 158a) and bearing

cover plate (pos. 155).

7. Pull shaft (pos. 51) out of stator housing (pos. 150).

8. Pull bearing (pos. 153) off shaft (pos. 51).

9. Remove O-ring (pos. 159) and spring (pos. 158).

10. Pull bearing (pos. 154) off shaft (pos. 51).

5.6.2 Assembly

1. Push bearing (pos. 154) onto shaft (pos. 51).

2. Fit spring (pos. 158) and O-ring (pos. 159).

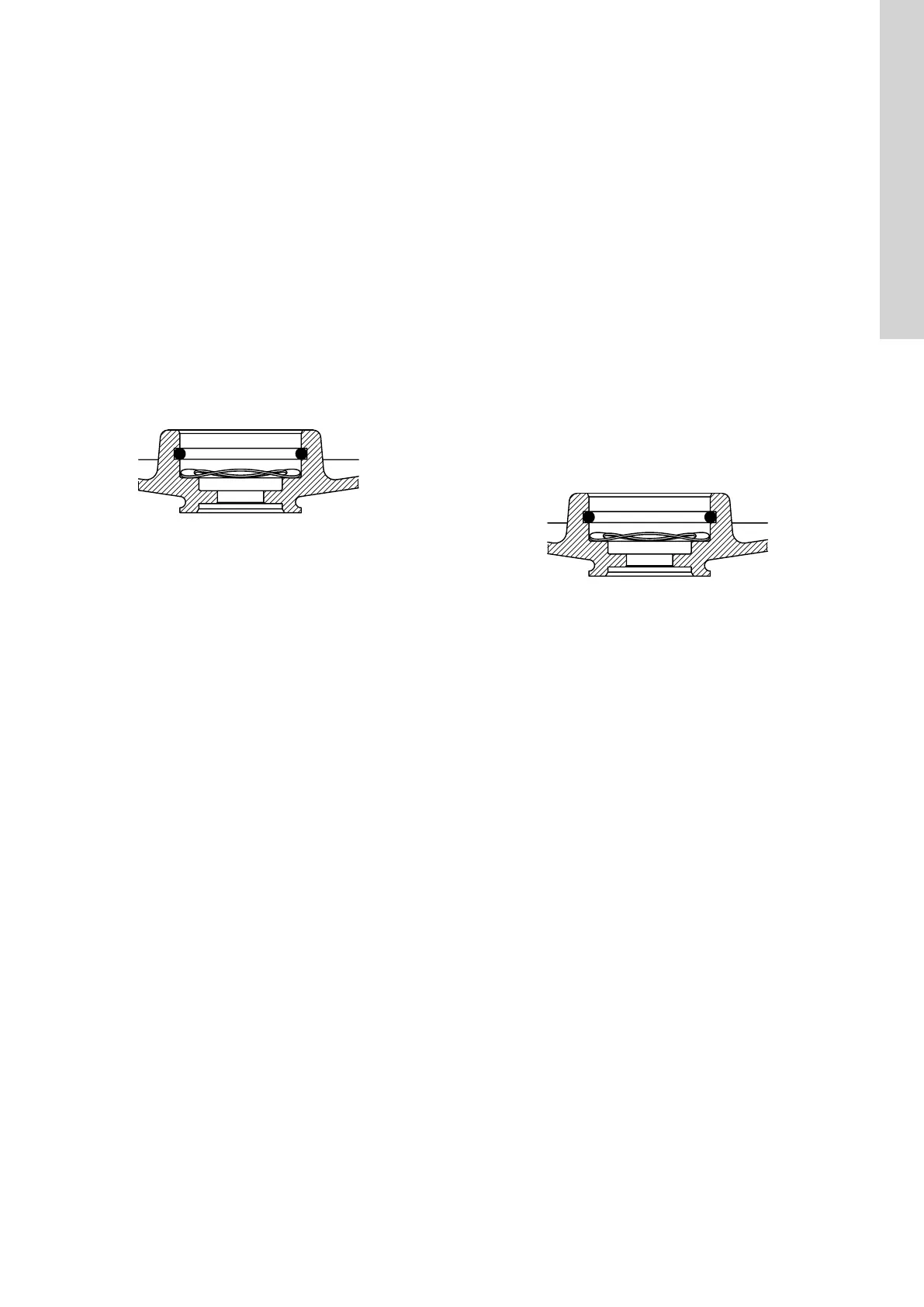

TM044441

Correct fitting of spring and O-ring

3. Push bearing (pos. 153) onto shaft (pos. 51).

4. Fit shaft (pos. 51) into stator housing (pos. 150).

5. Fit bearing cover plate (pos. 155), O-ring (pos. 158a) and

diverting disc (pos. 79). Lubricate the surface of the cover plate

(pos. 155) turning against the bearing. Lubricate the O-ring (pos.

158a). For correct lubricant, see the section on tightening

torques and lubricants.

6. Fit gasket (pos. 157a) and motor flange (pos. 156b).

7. Fit and cross-tighten screws (pos. 181). See the section on

tightening torques and lubricants.

8. Fit and lubricate the seal ring (pos. 159a). For correct

lubricant, see the section on tightening torques and lubricants.

9. Fit the fan (pos. 156).

10. Fit fan cover (pos. 151).

11. Fit and tighten screws (pos. 152).

Related information

3. Tightening torques and lubricants

5.7

MG 90, MG 100, MG 112 and MG 132 motors

5.7.1 Dismantling

1. Only cast iron pumps: Remove screws (pos. 2b).

2. Only cast iron pumps: Remove discharge part (pos. 2).

3. Remove screws (pos. 152).

4. Remove fan cover (pos. 151).

5. Remove fan (pos. 156) and seal ring (pos. 159a).

6. Remove staybolts (pos. 181).

7. Remove motor flange (pos. 156b), gasket (pos. 157a) and

bearing cover (pos. 156a).

8. Remove diverting disc (pos. 79), O-ring (pos. 158a) and bearing

cover plate (pos. 155).

9. Pull shaft (pos. 51) out of stator housing (pos. 150).

10. Pull bearing (pos. 153) off shaft (pos. 51).

11. Remove O-ring (pos. 159) and spring (pos. 158).

12. Pull bearing (pos. 154) off shaft (pos. 51).

5.7.2 Assembly

1. Push bearing (pos. 154) onto shaft (pos. 51).

2. Fit spring (pos. 158) and O-ring (pos. 159).

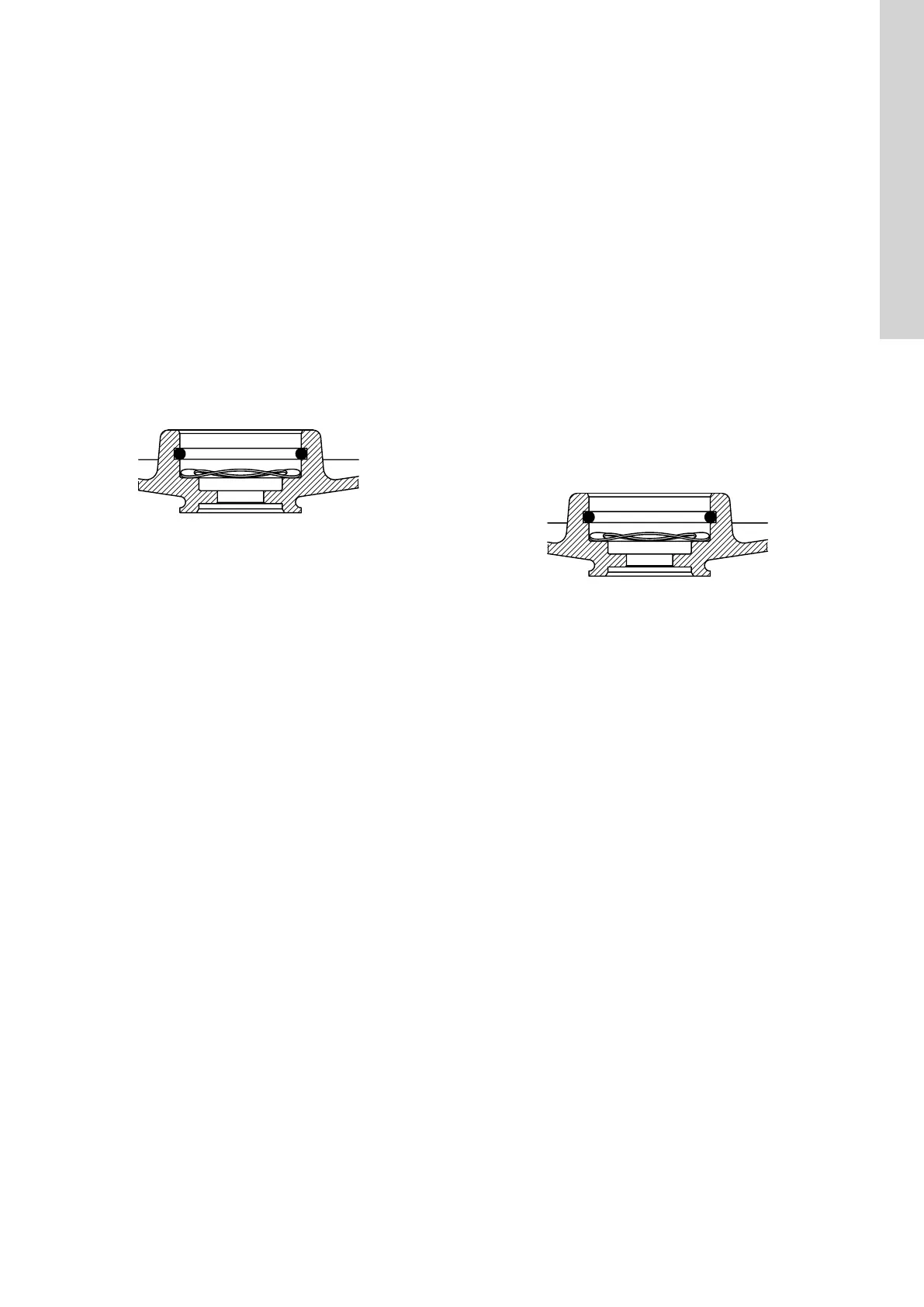

TM044441

Correct fitting of spring and O-ring

3. Push bearing (pos. 153) onto shaft (pos. 51).

4. Fit shaft (pos. 51) into stator housing (pos. 150).

5. Fit bearing cover plate (pos. 155), O-ring (pos. 158a) and

diverting disc (pos. 79). Lubricate the surface of the cover plate

(pos. 155) turning against the bearing. Lubricate the O-ring (pos.

158a). For correct lubricant, see the section on tightening

torques and lubricants.

6. Fit bearing cover (pos. 156a), gasket (pos. 157a) and motor

flange (pos. 156b).

7. Fit and cross-tighten staybolts (pos. 181). See the section on

tightening torques and lubricants.

8. Fit and lubricate the seal ring (pos. 159a). For correct see the

section on tightening torques and lubricants.

9. Fit the fan (pos. 156).

10. Fit fan cover (pos. 151).

11. Fit and tighten screws (pos. 152). See the section on tightening

torques and lubricants.

12. Only cast iron pumps: Fit discharge part (pos. 2).

13. Only cast iron pumps: Fit and tighten screws (pos. 2b).

Related information

3. Tightening torques and lubricants

17

English (GB)

Loading...

Loading...