8. Fit spring (pos. 108) and driver (pos. 112).

TM044326

Fitting the spring and driver

9. Fit short spacing pipe (pos. 64a), impeller (pos. 49), gasket

(pos. 139c) and chamber (pos. 4g).

10. Fit gasket (pos. 139b), spacing pipe (pos. 64), impeller (pos. 49)

and chamber (pos. 4).

11. Continue the assembly until clamp (pos. 64c). For correct fitting

of chambers and impellers, see the section on order of

assembly for chambers and impellers.

12. Fit impeller (pos. 49), clamp (pos. 64c), washers (pos. 66) and

nut (pos. 67).

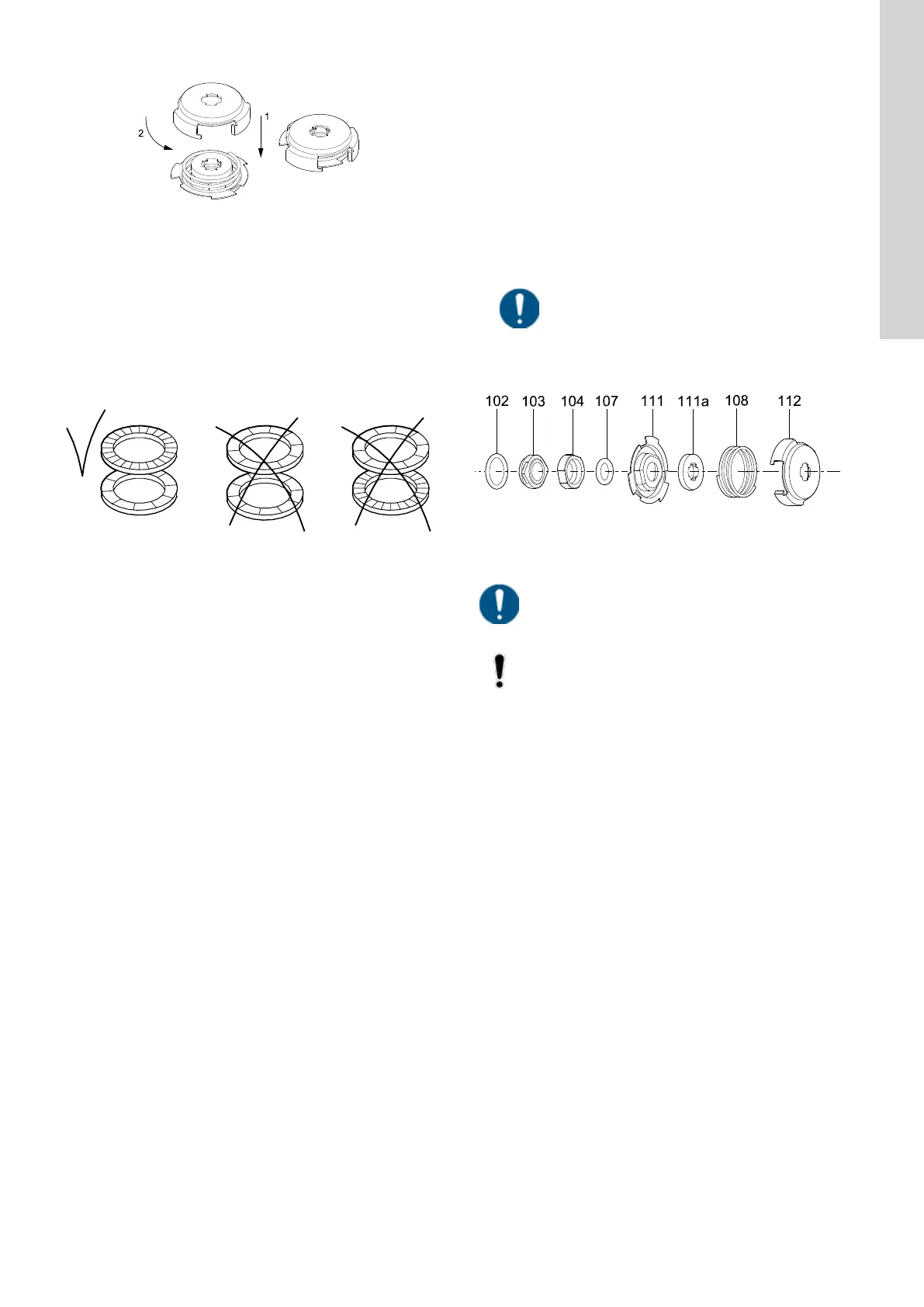

TM021057

Correct fitting of washers

13. Hold clamp (pos. 64c), and tighten nut (pos. 67). See the

section on tightening torques and lubricants.

14. Fit gasket (pos. 139b).

15. Fit inlet part (pos. 6).

16. Fit and cross-tighten staybolts (pos. 26). See the section on

tightening torques and lubricants.

Related information

3. Tightening torques and lubricants

5.6.2 Assembly

5.7.2 Assembly

8.1 Key for CM 1, 3, 5

5.5 CM 10, 15, 25, stainless steel

5.5.1 Dismantling

1. Remove staybolts (pos. 26).

2. Remove clamping flange (pos. 6a) and sleeve (pos. 16).

3. Remove the chamber plate (pos. 4f).

4. Hold clamp (pos. 64c), and remove nut (pos. 67).

5. Remove lock washers (pos. 66) and clamp (pos. 64c).

6. Remove impeller (pos. 49).

7. Remove spacing pipe (pos. 64e), bearing ring (pos. 47a) and

chamber for bearing (pos. 4a).

Step 7 applies only to pumps with six or more stages.

8. Continue the dismantling until shaft seal (pos. 105).

9. Remove shaft seal (pos. 105).

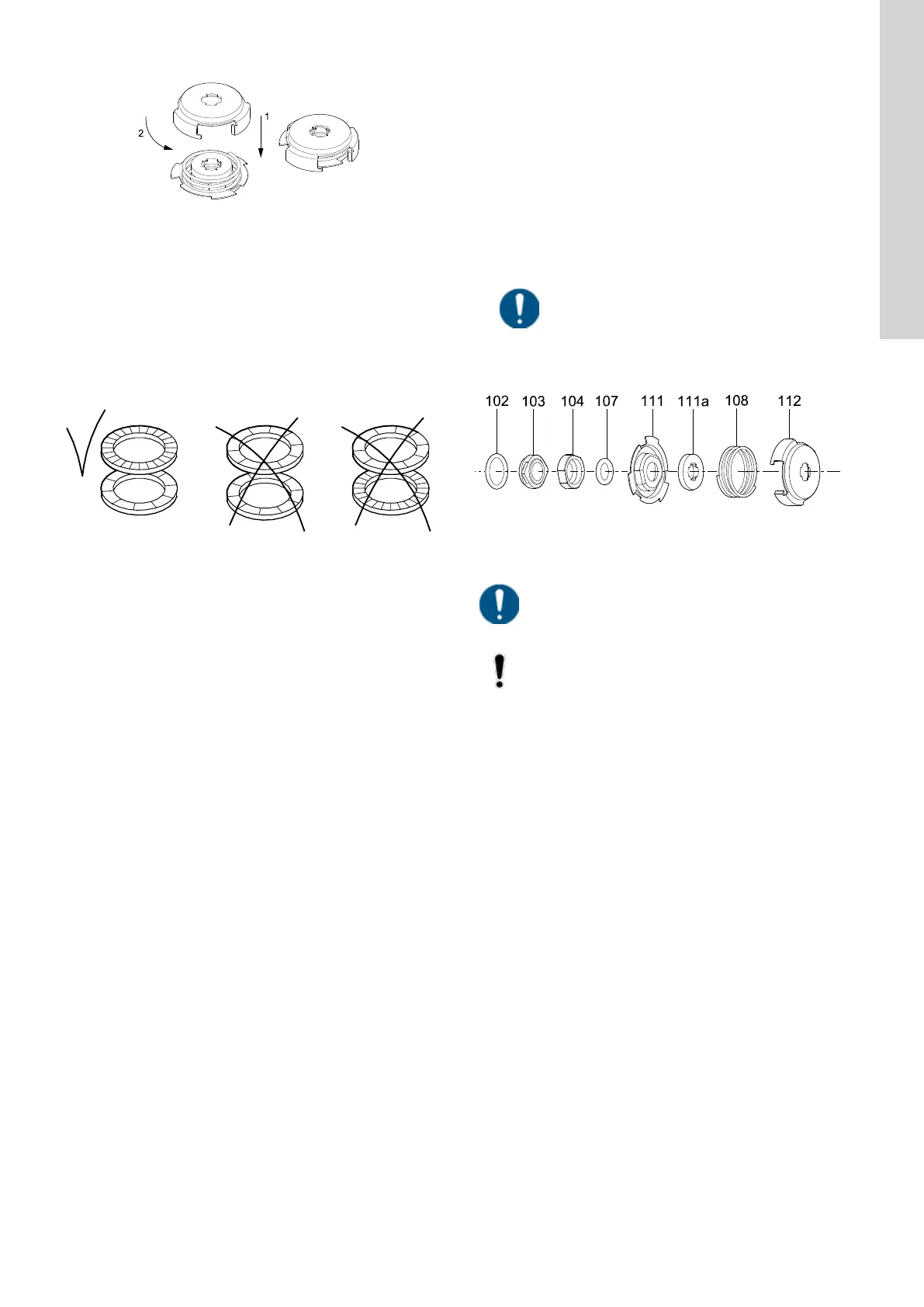

TM044327

Exploded view of shaft seal

10. Remove O-ring (pos. 31) and cover plate (pos. 32).

Dismantling of MG 71 and MG 80, see the section on dis-

mantling.

Dismantling of MG 90, MG 100, MG 112 and MG 132, see

the section on dismantling.

It is advisable always to replace wear rings (pos. 45) and

wear ring retainers (pos. 65). See the section on checking

and replacing impellers and chambers.

Related information

5.6.1 Dismantling

5.7.1 Dismantling

5.8 Checking and replacing impellers and chambers

15

English (GB)

Loading...

Loading...