English (US)

6

4.6 Pump end without motor

Pump without motor (CR, CRI, CRN 1s, 1, 3, 5, 10, 15, and 20

only)

If you purchased a pump end without motor, the shaft seal has

been set from factory. Do not loosen the three set screws on the

shaft seal when attaching the motor.

Pump without motor (CR, CRN 32, 45 and 64 only)

If you purchased a pump end without motor, you must install the

shaft seal. The shaft seal is protected in its own box inside the

pump packing crate. To protect the shaft and bearings during

shipment, a transport protector is used. Remove the transport

protector prior to installation of the shaft seal. Read the seal

installation instructions which are included in the pump packing.

4.7 Drive-end motor bearing

Make sure to use the correct type of drive-end (DE) motor

bearing for the bare-shaft pump. Please check the specific pump

range and pump version stated on the nameplate and select the

corresponding DE bearing.

DE bearing CR 1-64 pump range

1)

Refer to the codes for pump version in section 5.2 Type keys.

2)

Factory product variants (FPV).

5. Identification

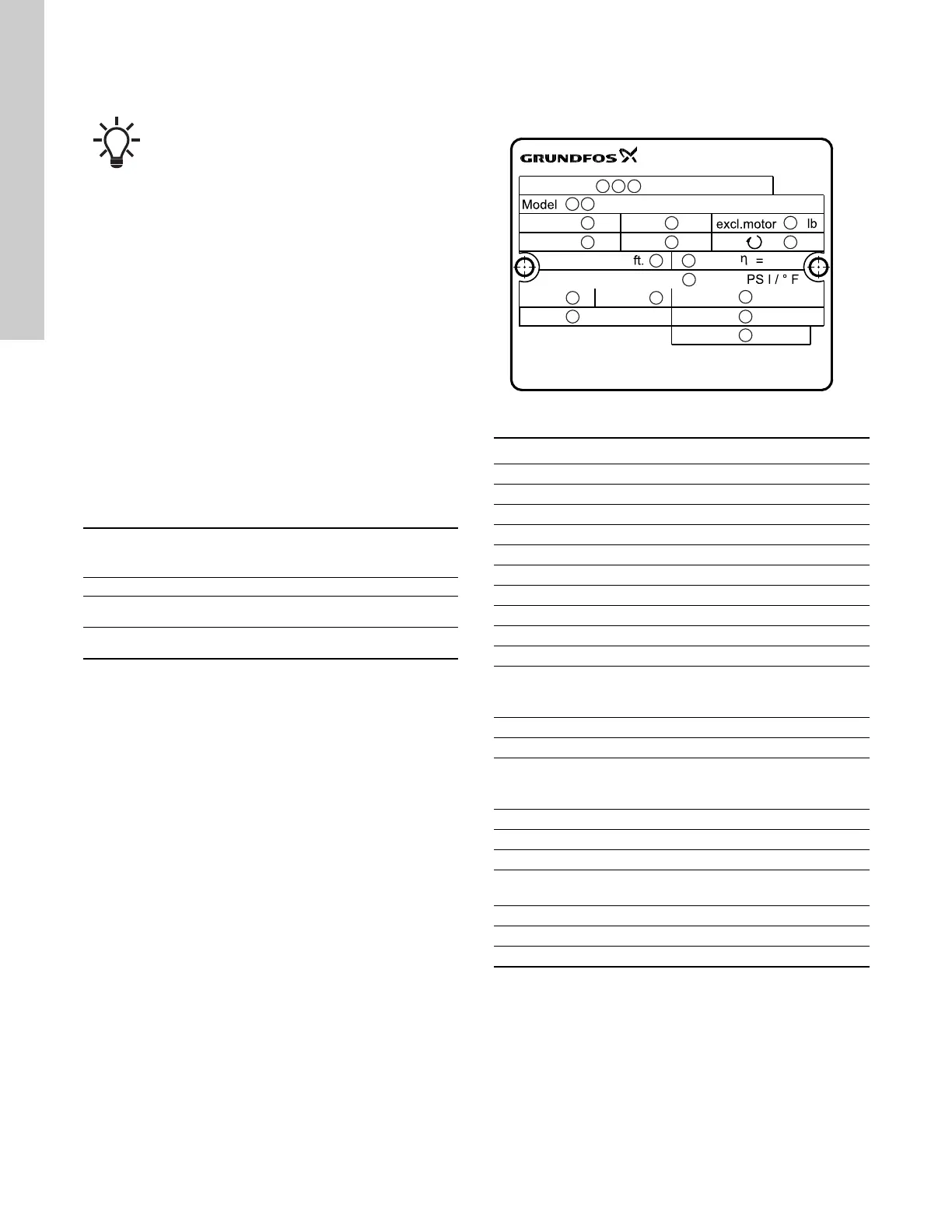

5.1 Nameplate data

The information on the pump nameplate is described below.

Fig. 2 Nameplate example

If the shipment consists of a complete unit (motor

attached to pump end), the position of the coupling

connecting the pump shaft to the motor shaft is set to

factory specifications. No adjustment is required.

If the shipment is a pump end without motor, follow

the adjustment procedures in section 15. Replacing

the motor.

Pump version

1)

Deep-groove ball

bearing

(62/63xx)

Angular contact

bearing

(73xx)

A Standard pump 0.33 - 10 HP 15 - 60 HP

T

Pump with thrust handling

device (THD)

2)

--

Z

Pump with bearing

flange

2)

0.33 - 60 HP Not allowed

TM07 5722 5019

Pos. Description

1Version

2 Product number

3 Serial number

4 Model

5 Type designation

6 Frequency

7 Rated speed

8 Weight excluding motor

9 Motor-rated power output

10 Rated flow rate

11

Direction of rotation

CCW: Counterclockwise

CW: Clockwise

12 Head at rated flow rate / Maximum head

13 Hydraulic efficiency at rated flow rate

14

Maximum system pressure / Maximum liquid

temperature.

Note: This field may have two sets of data.

15 Pump Energy Index, constant load

16 Pump Energy Index, variable load

17 Impeller diameter

18

External reference

(Other Equipment Manufacturer number)

19 Production code

20 Country of origin

21 Approval marks

Ver-PN-SN

p

DK-8850 Bjerringbro, Denmark

Hz

RPM

GPM

%

PEI

P code:

PEI

VL

CL

Imp.Dia.

(in)

H /Hmax

pmax/tmax

hp

[P2]

1 2 3

4 5

6

7

8

9

10

11

12 13

14

15 16

17

18 19

20

Loading...

Loading...