English (GB)

20

7. Service

In order to ensure a long service life and

dosing accuracy, wearing parts such as

diaphragms and valves must be regularly checked

for signs of wear. Where necessary, replace worn

parts with original spare parts made from suitable

materials.

Should you have any questions, please contact your

service partner.

7.1 Cleaning

If necessary, clean all pump surfaces with a dry and

clean cloth.

7.2 Service intervals

7.3 Perform service

Only spare parts and accessories from Grundfos

should be used for maintenance. The usage of

non-original spare parts and accessories renders

any liability for resulting damages null and void.

Information about carrying out maintenance can be

found in the service kit catalog on our homepage

(www.grundfosalldos.com).

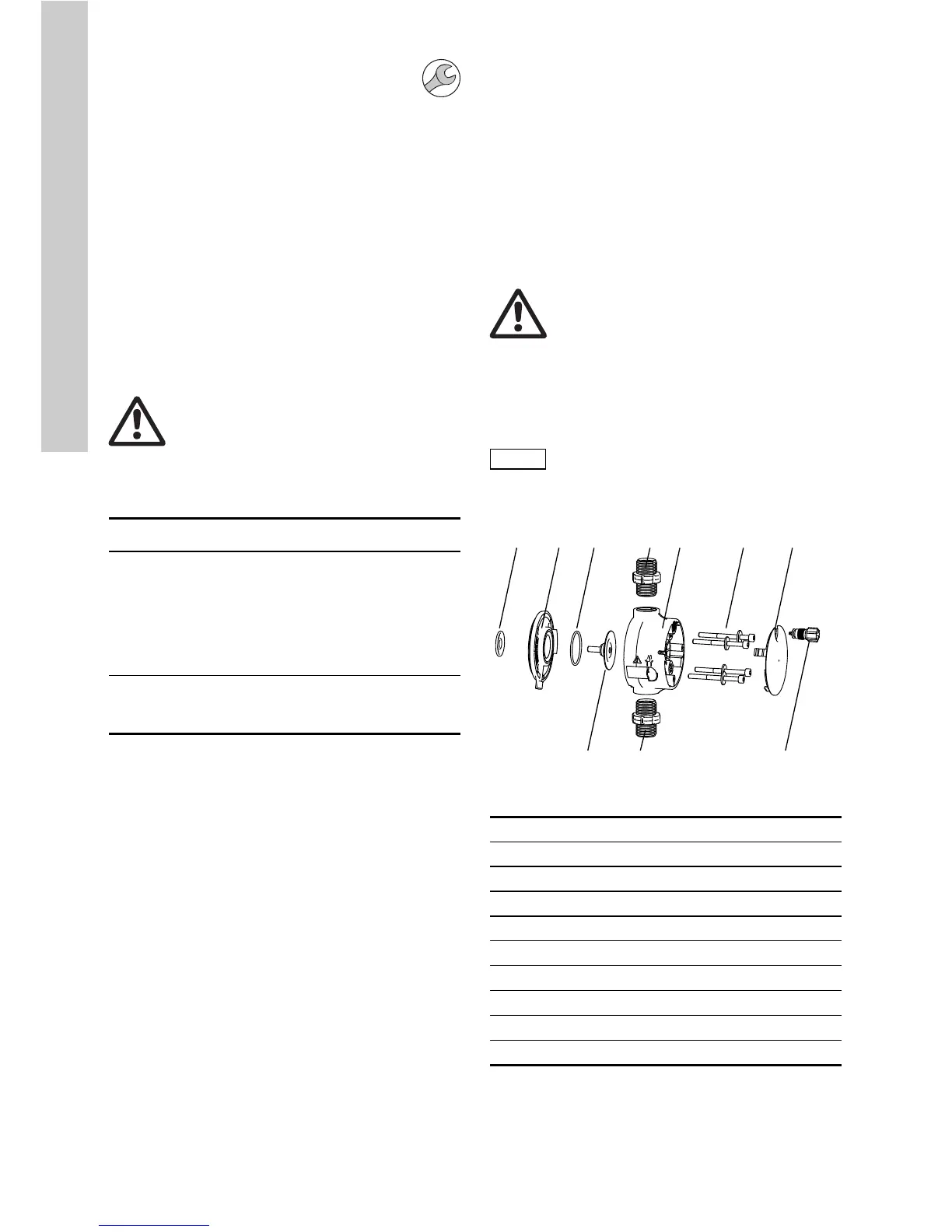

7.3.1 Dosing head overview

Fig. 10 Dosing head, exploded view

Warning

If the diaphragm leaks or is broken,

dosing liquid will escape from the drain

opening on the dosing head (see fig. 2).

Take suitable precautions to prevent

harm to health and damage to property

caused by escaping dosing liquid!

Check daily whether liquid is escaping

from the drain opening!

Interval Task

Every day

Check, if liquid leaks from

dosing head, drain opening or

valves (see fig. 2). If necessary,

tighten dosing head screws

(3 Nm), valves and cap nuts,

or perform service

(see 7.3 Perform service).

Every 2 years or

8000 operating

hours

Replace diaphragm and valves

(see 7.3 Perform service)

Warning

Risk of chemical burns!

When dosing dangerous media,

observe the corresponding precautions

in the safety data sheets!

Wear protective clothing (gloves and

goggles) when working on the dosing

head, connections or lines!

Do not allow any chemicals to leak

from the pump. Collect and dispose of

all chemicals correctly!

Loading...

Loading...