14

8. Installation

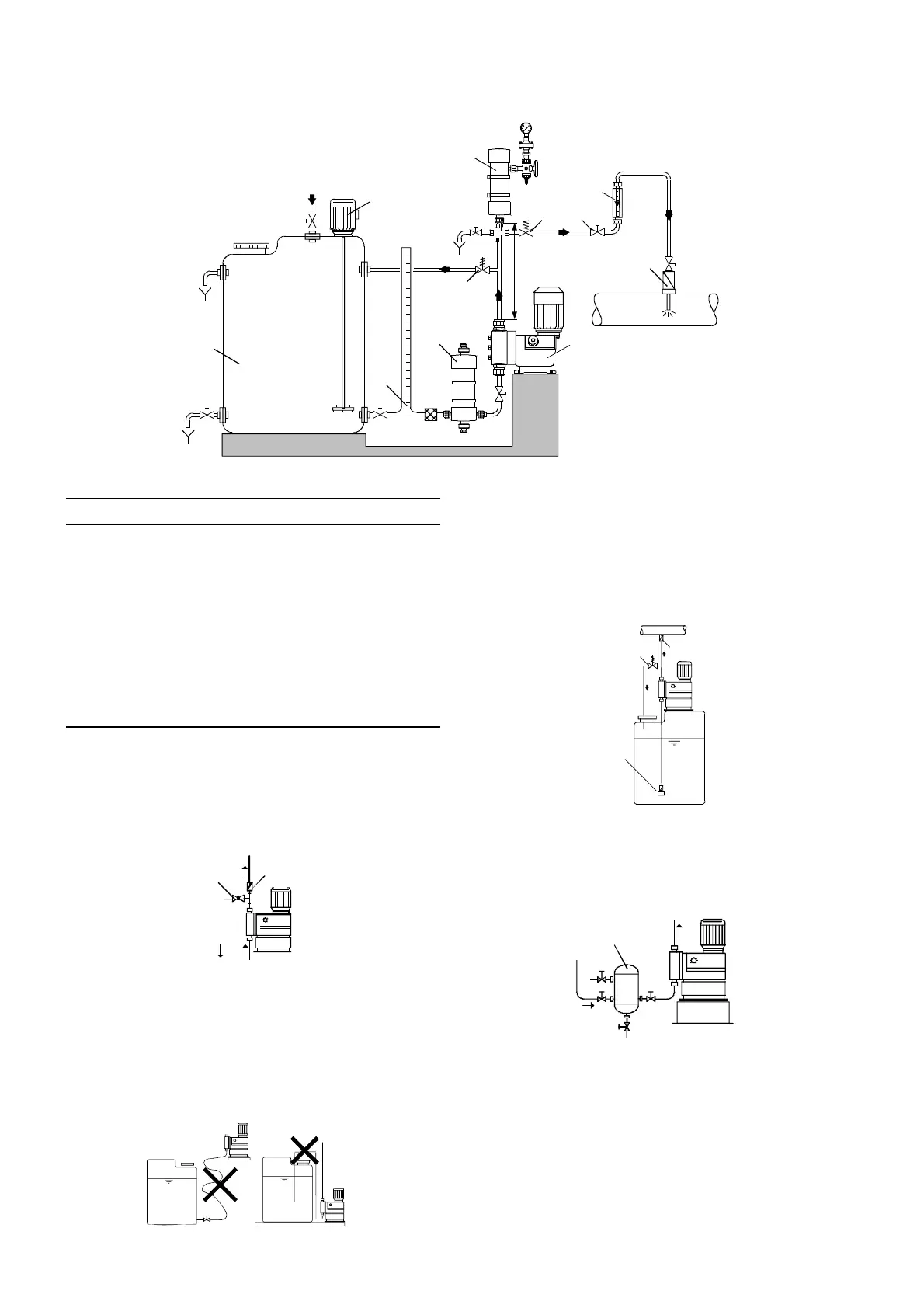

8.1 Optimum installation

Fig. 3 Example of optimum installation

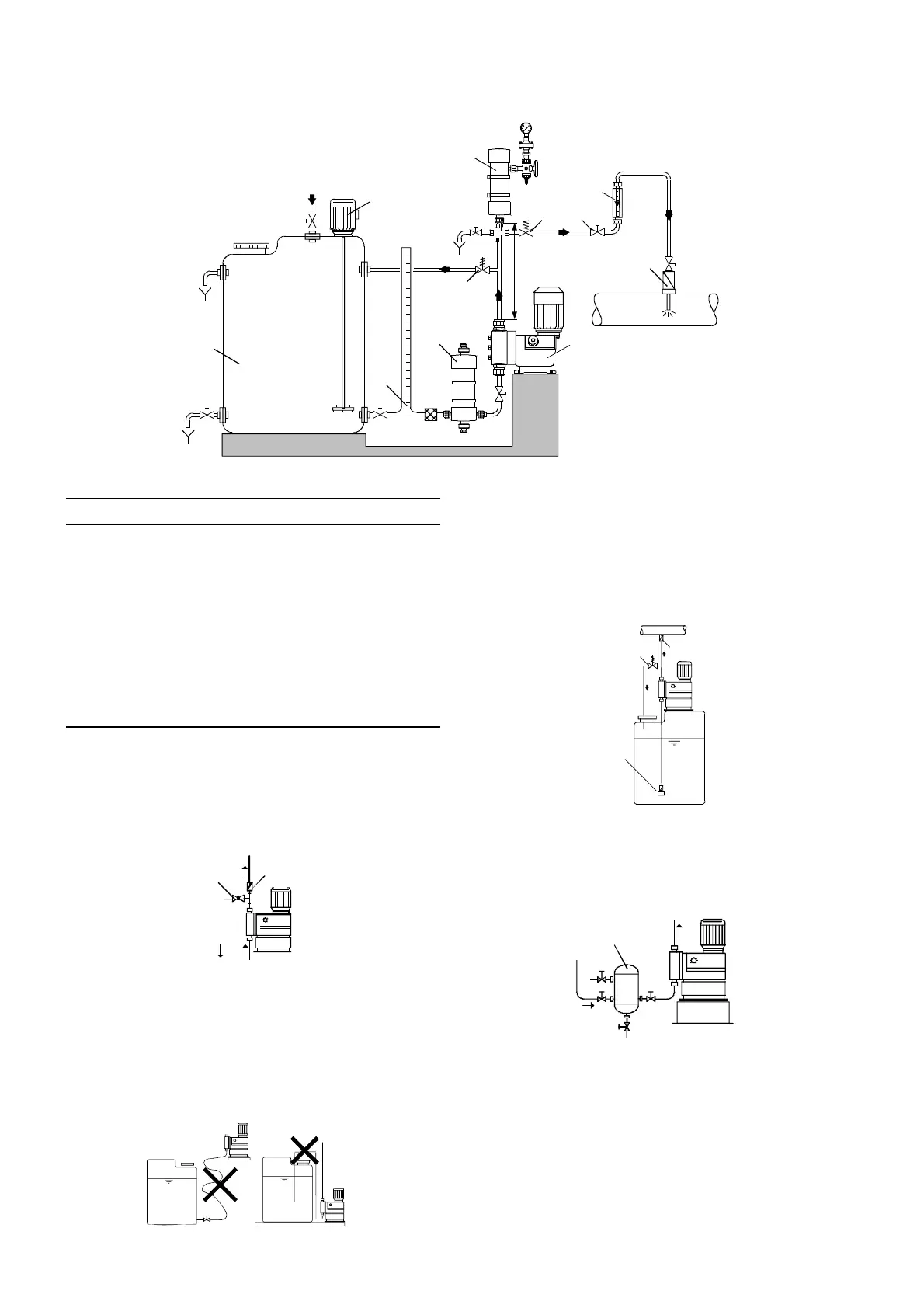

8.2 Installation tips

• For easy deaeration of the dosing head, install a ball valve

(11i) with bypass line (back to the dosing tank) immediately

after the discharge valve.

• In the case of long discharge lines, install a non-return valve

(12i) in the discharge line.

Fig. 4 Installation with ball valve and non-return valve

• When installing the suction line, observe the following:

– Keep the suction line as short as possible. Prevent it from

becoming tangled.

– If necessary, use swept bends instead of elbows.

– Always route the suction line up towards the suction valve.

– Avoid loops which may cause air bubbles.

Fig. 5 Installation of suction line

• For non-degassing media with a viscosity similar to water, the

pump can be mounted on the tank (observe the maximum

suction height).

• Flooded suction preferred.

• For media with a tendency to sedimentation, install the suction

line with filter (13i) so that the suction valve remains a few

millimetres above the possible level of sedimentation.

Fig. 6 Tank installation

• Note for suction-side installation: In dosing systems with a

suction line longer than 1 metre, depending on the dosing flow,

it may be necessary to install a properly sized pulsation

damper (4i) immediately before the pump suction valve.

Fig. 7 Installation with suction-side pulsation damper

TM03 6296 4506

1i

2i

3i

4i

5i

6i

9i

10i

8i

max. 1m

16i

7i

Max. 1 m

Pos. Components

1i Dosing tank

2i Electric agitator

3i Extraction device

4i Suction pulsation damper

5i Dosing pump

6i Relief valve

7i Pressure-loading valve

8i Pulsation damper

9i Measuring glass

10i Injection unit

TM03 6297 4506TM03 6298 4506

11i

12i

TM03 6299 4506TM03 6300 4506

p

10i

6i

13i

4i

Loading...

Loading...