9

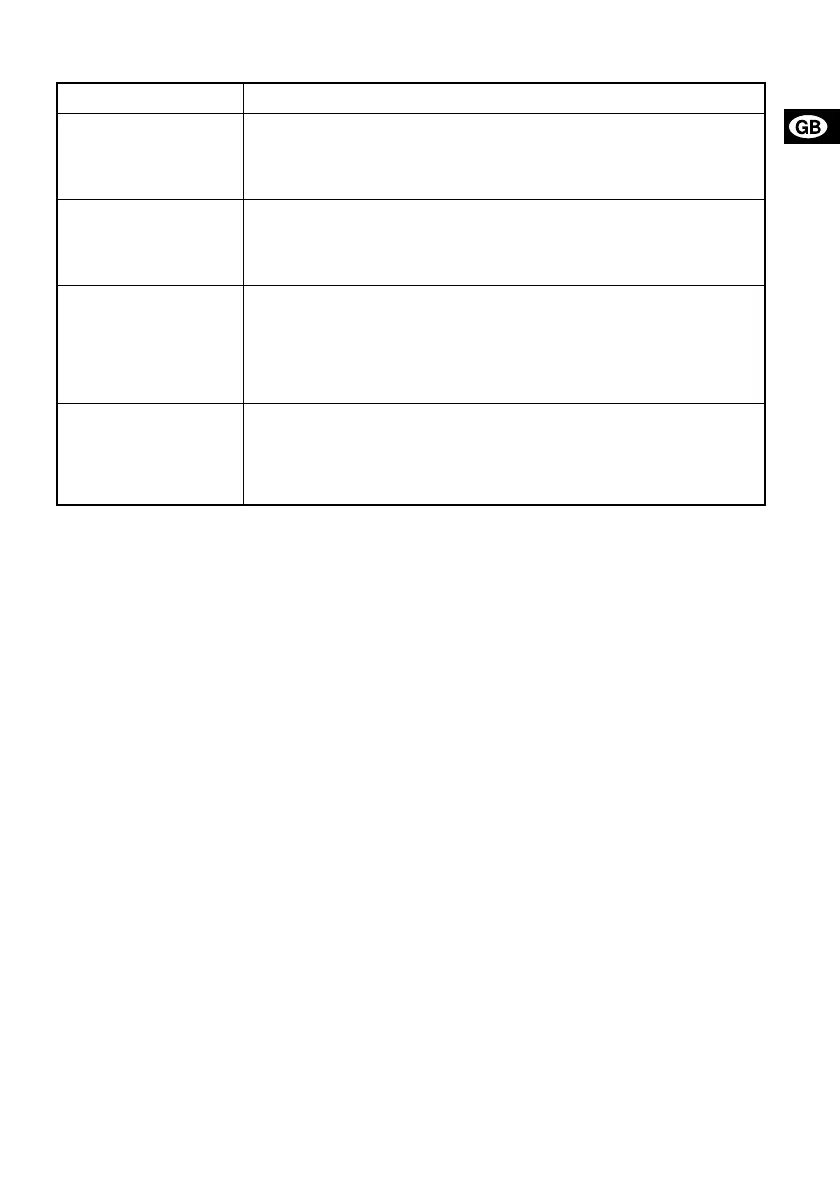

5. Fault finding chart

6. Disposal

Disposal of this product or parts of it must be carried

out according to the following guidelines:

1. Use the local public or private waste collection

service.

2. In case such waste collection service does not

exist or cannot handle the materials used in the

product, please deliver the product or any haz-

ardous materials from it to your nearest GRUND-

FOS company or service workshop.

Fault Cause

1. Motor does not start. a) Supply failure.

b) Pump switched off by float switch/vertical level switch.

c) Fuses are blown.

d) Thermal relay has cut out the electricity supply to the motor

(see section 2. Electrical connection).

2. Thermal relay trips

out after short time

of operation.

a) Temperature of pumped liquid higher than that stated in section 1.2 Operat-

ing conditions.

b) Pump partly blocked by impurities (see section 4. Operation and mainte-

nance).

c) Pump mechanically blocked (see section 4. Operation and maintenance).

3. Pump runs but gives

insufficient water.

a) Pump partly blocked by impurities (see section 4. Operation and mainte-

nance).

b) Discharge pipe/hose partly blocked. Check the non-return valve, if fitted.

c) Check the impeller, the pump housing and the sealing part (see section

4. Operation and maintenance).

d) Three-phase pumps only: Incorrect direction of rotation

(see section 2.1 Checking of direction of rotation).

4. Pump runs but gives no

water.

a) Pump blocked by impurities (see section 4. Operation and maintenance).

b) Non-return valve, if fitted, in discharge pipe/hose blocked in closed position.

c) Liquid level is too low. During normal operation, the liquid level must be

above the strainer.

d) Pumps with float switch: The free cable of the float switch is too long (see

section 3.3 Adjustment of float switch).

Subject to alterations.

Loading...

Loading...