8

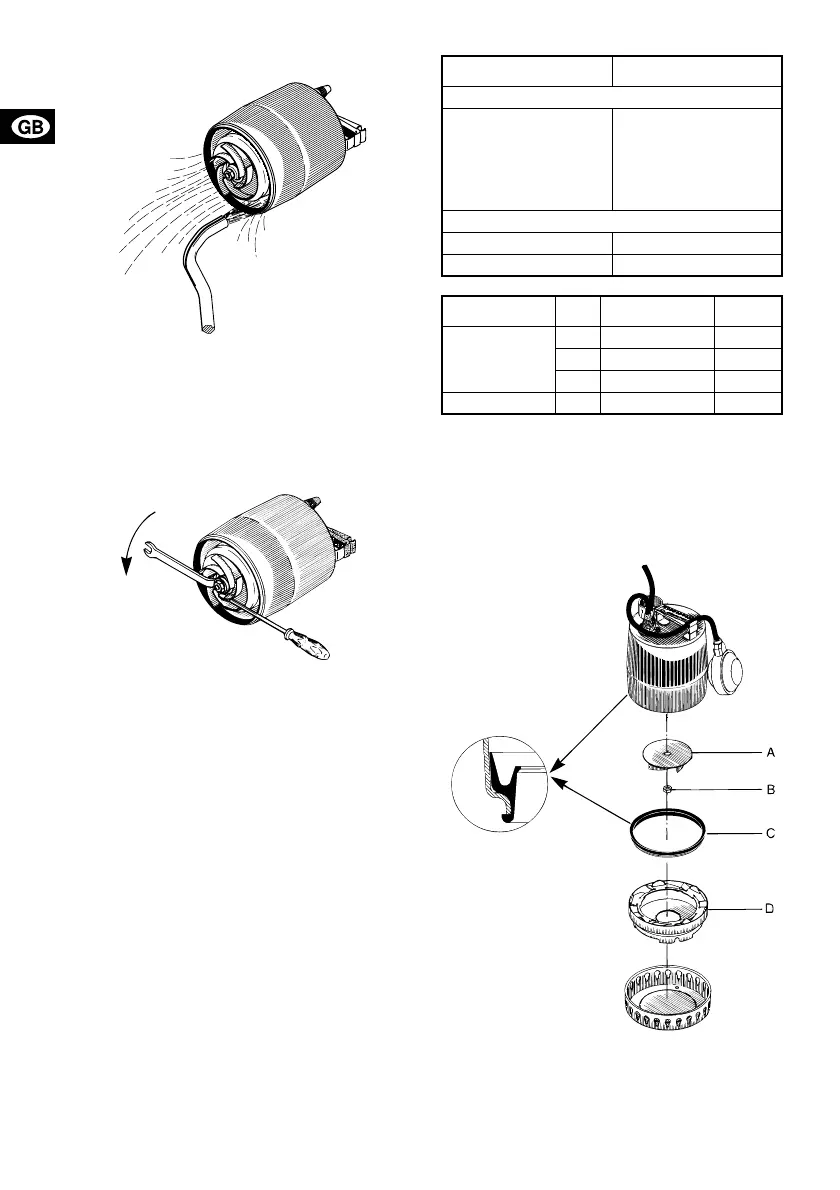

Fig. 13

4. Check that the impeller can rotate freely. If not,

remove the impeller:

• Slacken and remove the nut on the motor shaft

(13 mm). Prevent the impeller from rotating by

means of a screwdriver, see fig. 14.

• Clean the impeller and around the shaft.

Fig. 14

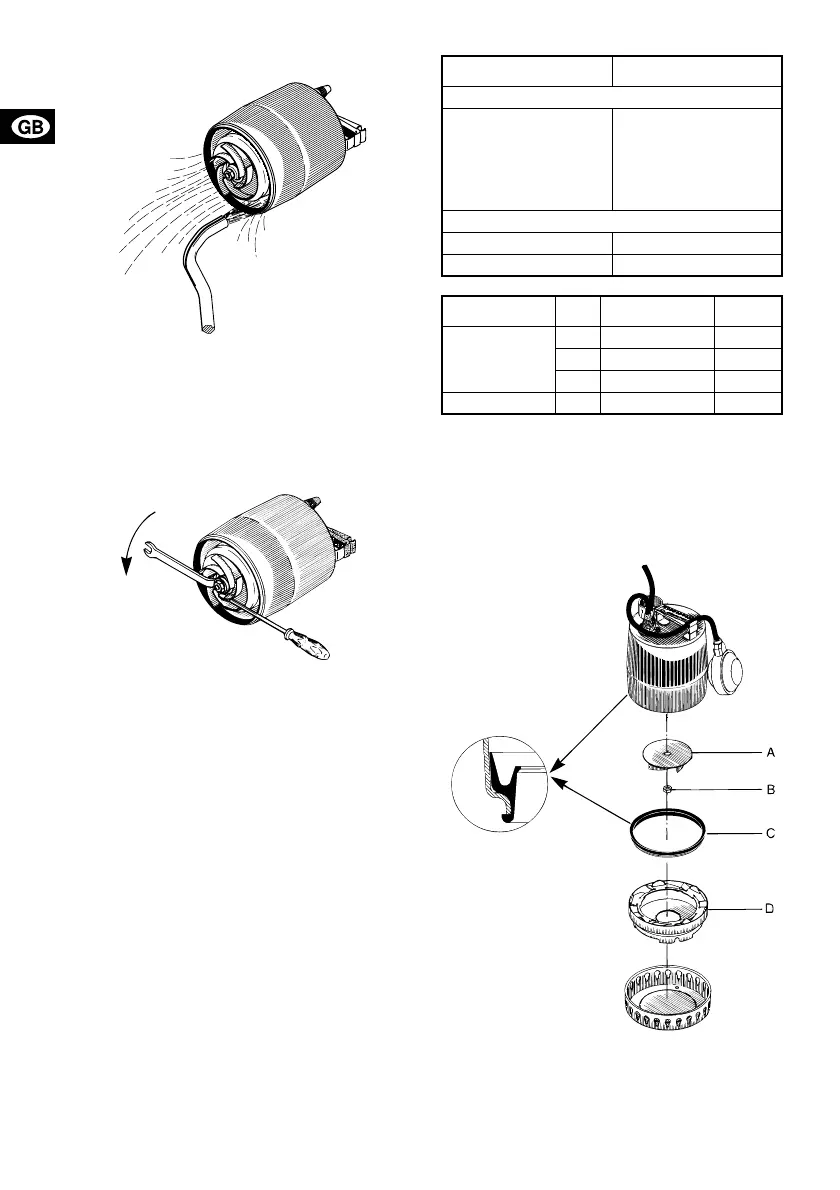

5. Check the impeller, the pump housing and the

sealing part. Replace possible defective parts.

Assemble the pump in reverse order of dismantling.

Note: Check before and when fitting the pump hous-

ing that the sealing part is positioned correctly, see

fig. 15. Moisten the sealing part with water to facili-

tate the fitting.

4.2 Replacement of parts

The impeller, the pump housing and the sealing part

can be replaced.

The part numbers and the components included in

the service kits will appear from the tables below and

fig. 15.

If pump components other than those mentioned

above are damaged or defective, please contact

your pump supplier.

A possible replacement of the cable or the float

switch/vertical level switch must be carried out by an

authorised GRUNDFOS service workshop.

Fig. 15

TM00 1555 0493TM00 1556 0493

Pump type Part number

Impeller kit

KP 150, 50 Hz

KP 250, 50 Hz

KP 150, 60 Hz

KP 250, 60 Hz

KP 350, 50 Hz

KP 350, 60 Hz

01 57 78

01 57 79

01 57 83

01 57 84

01 57 85

01 57 86

Pump housing

KP 150 and KP 250 01 57 70

KP 350 01 57 71

Service kit Pos. Description Qty.

Impeller kit

A Impeller 1

BNut 1

C Sealing part 1

Pump housing D Pump housing 1

TM00 1557 2297

Loading...

Loading...