14.3 Fault finding chart

DANGER

Electric shock

Death or serious personal injury

‐ Before starting any work on the product, make sure

that the power supply has been switched off and that it

cannot be accidentally switched on.

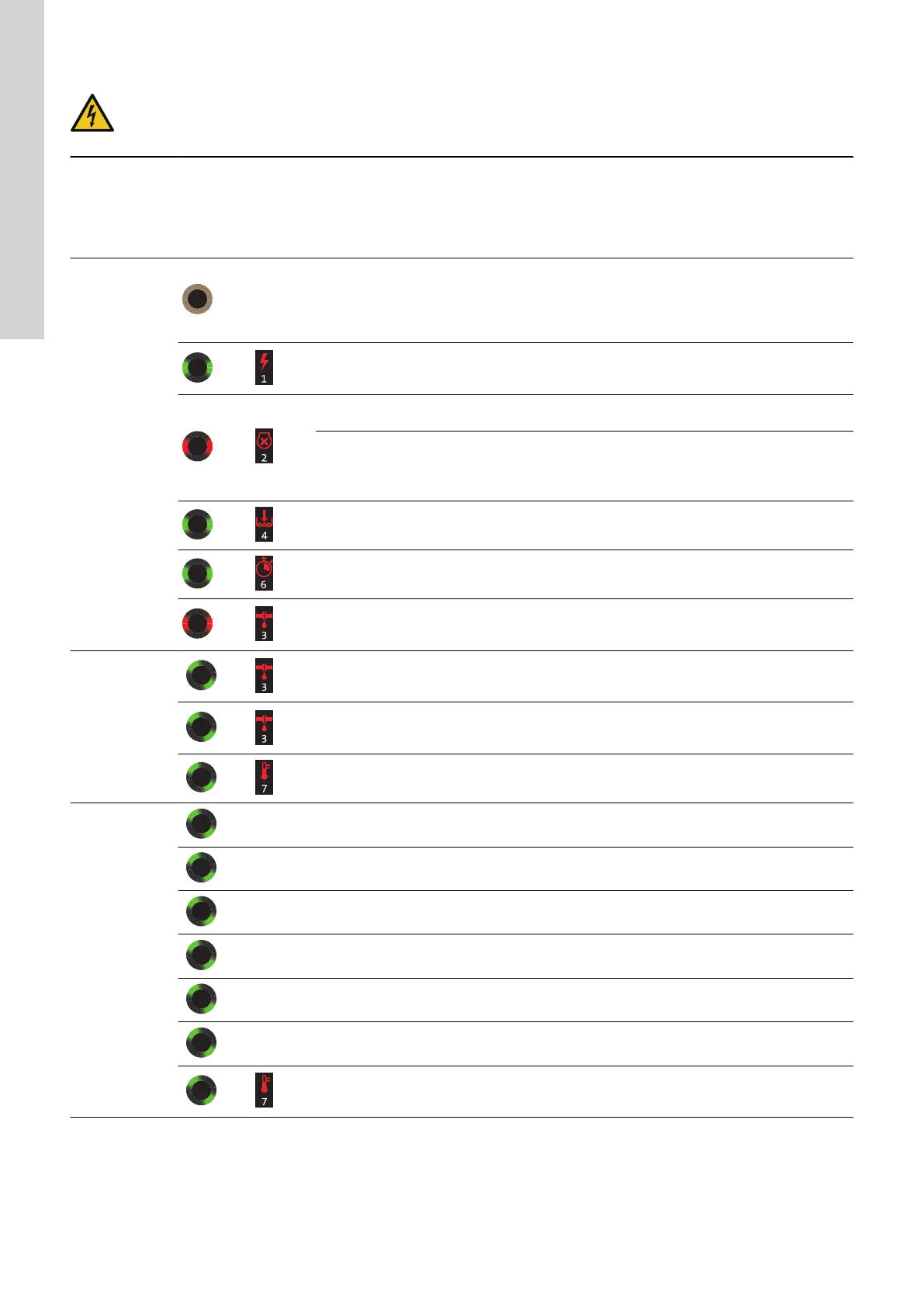

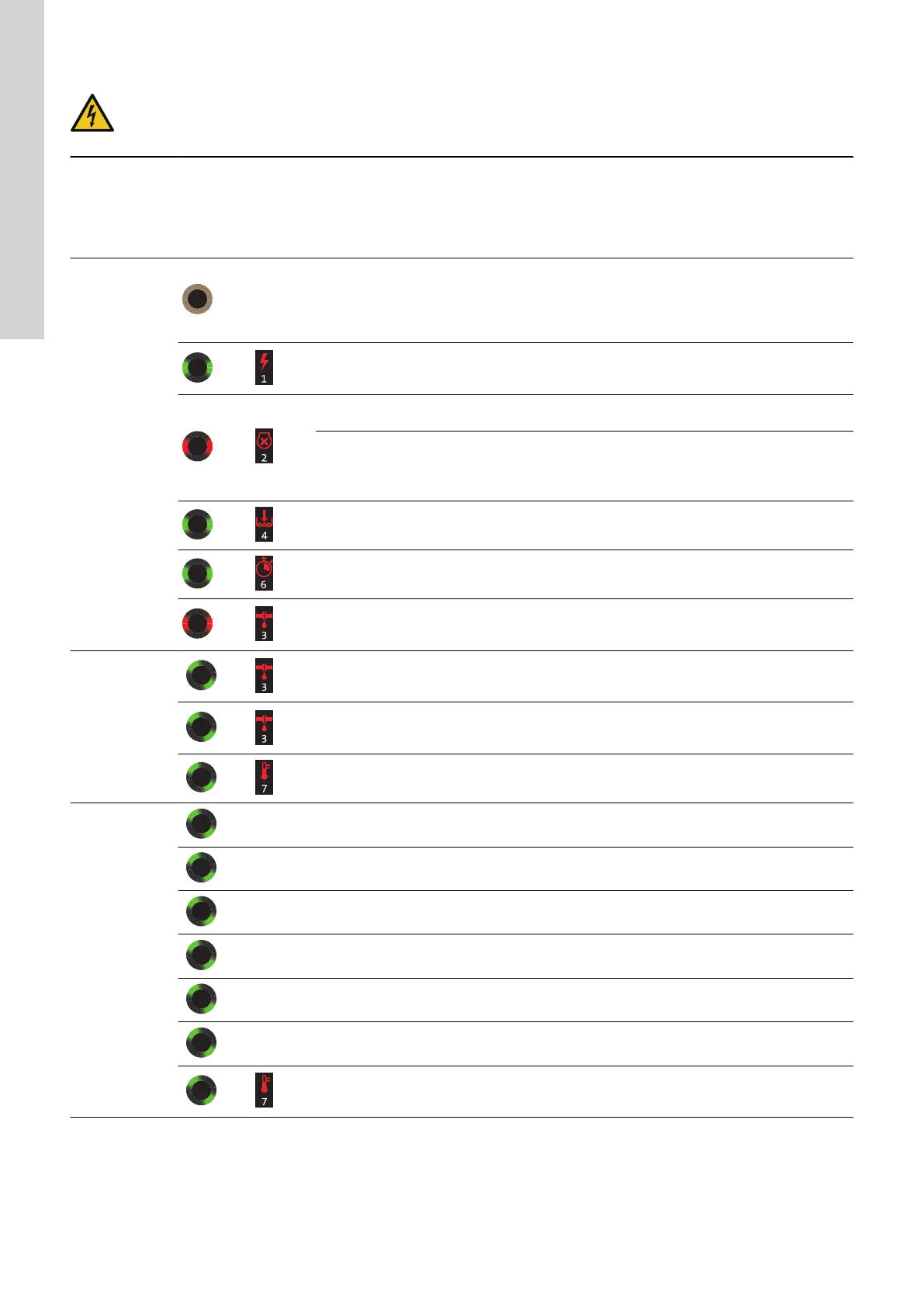

Fault

Grundfos Eye

Indicator light

Automatic reset

Cause Remedy

The pump is not

running.

- - Power supply failure.

Switch on the power supply.

Check the cables and cable connections

for defects and loose connections and

check for blown fuses in the electrical in-

stallation.

Yes

The power supply is out of prescribed

voltage range.

Check the power supply and the pump

nameplate. Reestablish the power supply

within the prescribed voltage range.

No The shaft seal has seized up.

See section Starting up the product after

standstill.

No The pump is blocked by impurities.

See section Starting up the product after

standstill.

Contact Grundfos Service if the problem

persists.

Yes Dry running.

Check the water source, and prime the

pump.

No

The maximum runtime has been ex-

ceeded.

Check the installation for leakage and re-

set the alarm.

No

The internal non-return valve is defec-

tive or blocked in completely or partly

open position.

Clean, repair or replace the non-return

valve. See section Servicing the product.

The pump is run-

ning.

-

Leakage from the pipe system, or the

non-return valve is not properly closed

due to impurities.

Check and repair the pipe system, or

clean, repair or replace the non-return

valve.

- Small continuous consumption.

Check the taps and reconsider the usage

pattern (ice machines, water evaporators

for air-conditioning, etc.).

-

The temperature of the pump and wa-

ter is below 3 °C.

Consider protecting the pump and the in-

stallation against frost.

The pump per-

formance is insuf-

ficient.

-

- The pump inlet pressure is too low. Check the inlet conditions of the pump.

- The pump is undersized. Replace the pump with a bigger pump.

- -

The inlet pipe, the inlet strainer or the

pump is partly blocked by impurities.

Clean the inlet pipe or the pump.

- - There is a leakage in the inlet pipe. Repair the inlet pipe.

- -

There is air in the inlet pipe or the

pump.

Prime the inlet pipe and the pump.

Check the inlet conditions of the pump.

- -

The required outlet pressure is too low

for the installation.

Increase the pressure setting (arrow up).

Yes

The maximum temperature has been

exceeded and the pump is running at

reduced performance.

Check the cooling conditions. Protect the

pump against direct sunlight or any nearby

heat sources.

22

English (GB)

Loading...

Loading...