12

5.7 Fitting the submersible drop cable

It is recommended to join the submersible drop cable

and the motor cable by means of a Grundfos cable

termination kit, type KM.

For larger cross-sections, please contact Grundfos.

5.8 Pipework connection

If a tool, e.g. a chain pipe wrench, is used when the

riser pipe is fitted to the pump, the pump must only

be gripped by the pump discharge chamber.

When connecting plastic pipes, a compression

coupling should be used between the pump and the

first pipe section.

Note: For pumps fitted with plastic pipes, the

expansion of the pipes when loaded should be taken

into consideration, when deciding on the installation

depth of the pump.

Where flanged pipes are used, the flanges should

be slotted to take the submersible drop cable.

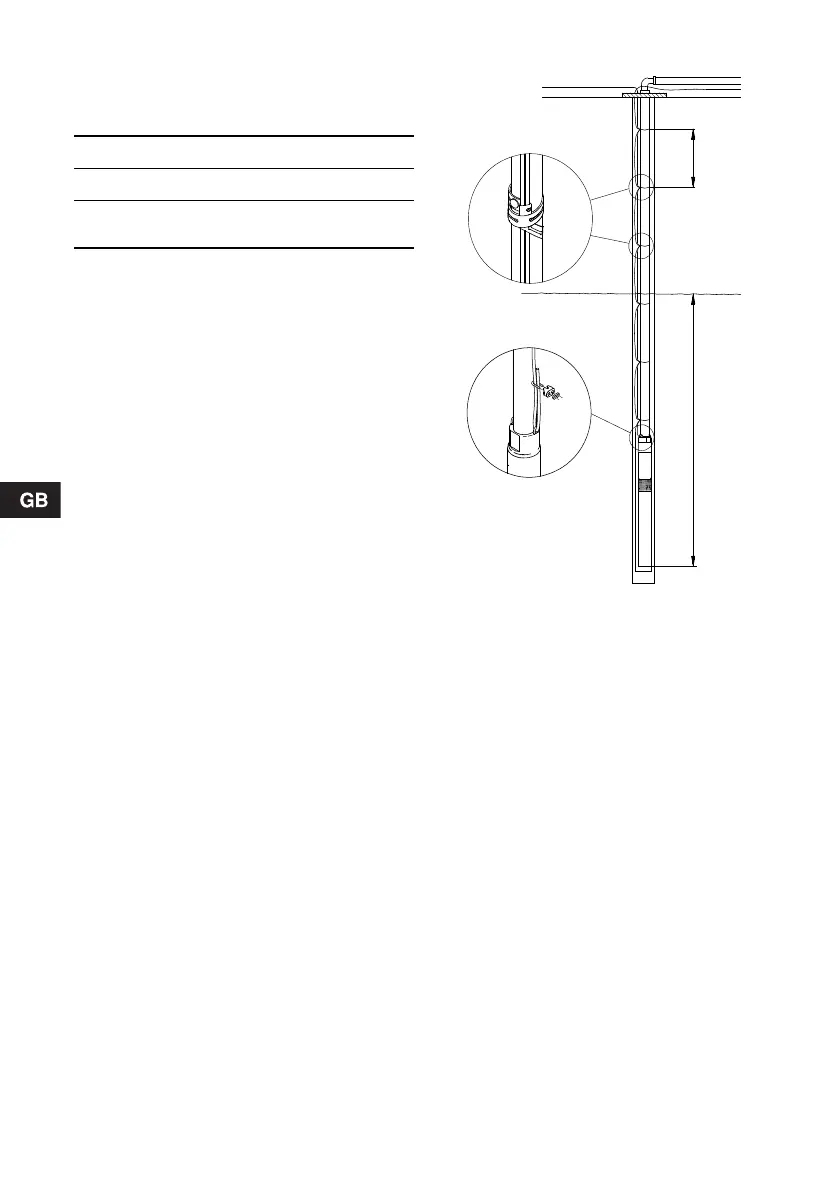

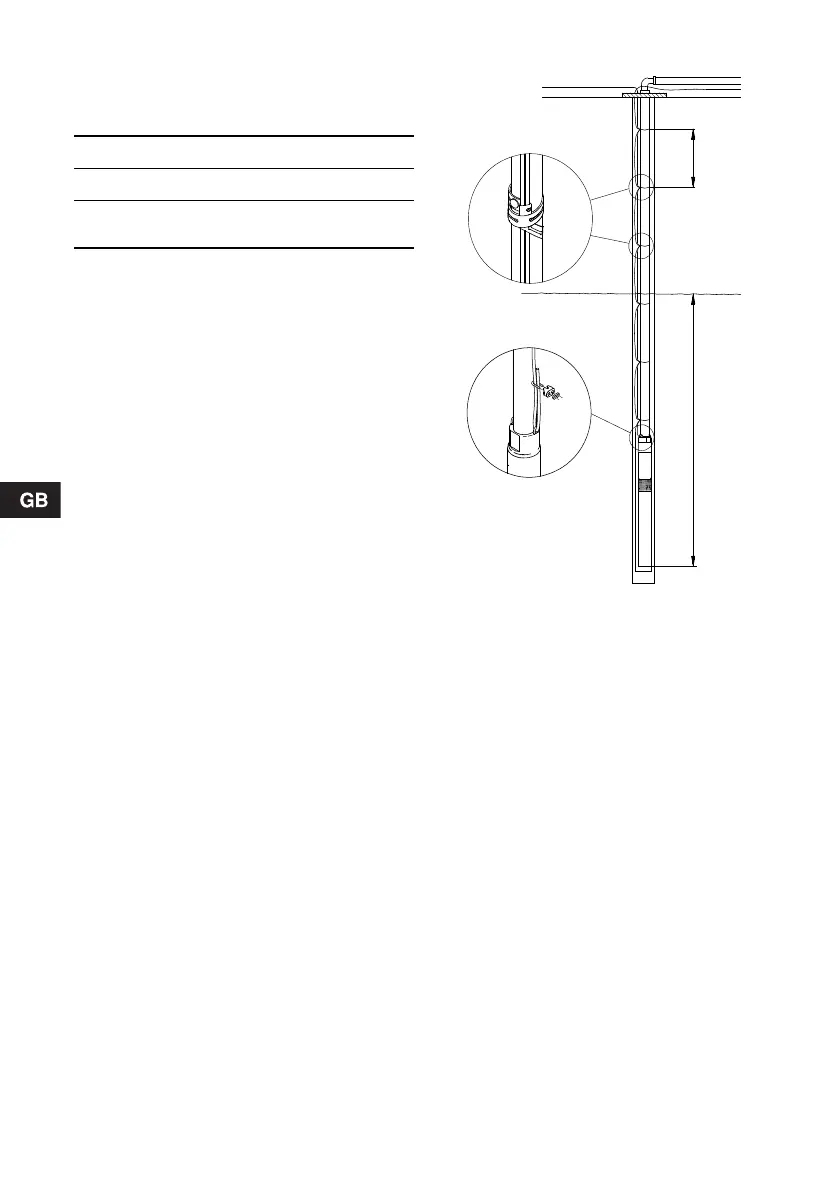

Figure 10 shows a pump installation with indication of:

• position of cable clips, pos. 1, and distance

between the clips.

• fitting of straining wire, pos. 2.

• maximum installation depth below the static water

level.

Fig. 10

5.8.1 Cable clips

Cable clips must be fitted every 3 metres, see fig. 10.

When connecting plastic pipes, some slackness

must be left between each cable clip as plastic pipes

expand when loaded.

Where flanged pipes are used, the cable clips

should be fitted above and below each joint.

5.8.2 Installation depths

Maximum installation depth below the static water

level: 150 metres, see fig. 10.

Minimum installation depths below the dynamic

water level:

• Vertical installation:

During start-up and operation, the pump must

always be completely submerged in water.

• Horizontal installation:

The pump must be installed and run at least

0.5 metres below the dynamic water level.

If there is a risk that the pump might be covered

by mud, the pump must always be fitted in a flow

sleeve.

Cable termination kit, type KM

Cross-sectional area Product number

1.5 to 2.5 mm² 96021462

4.0 to 6.0 mm² 96021473

TM01 0480 4397

Loading...

Loading...