16

9.1 Megging

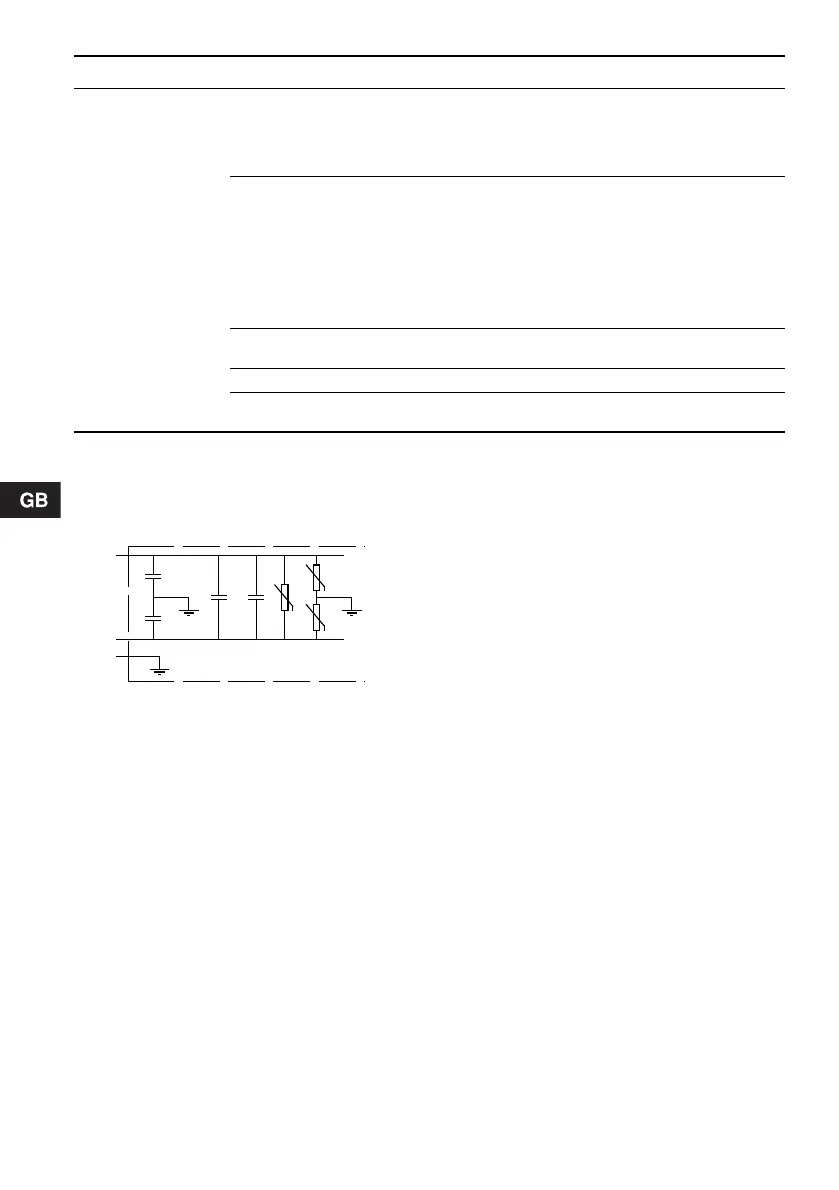

Megging of an installation incorporating SQ/SQE

pumps is not allowed, as the built-in electronics may

be damaged, see fig. 12.

Fig. 12

4. Frequent starts

and stops.

a) The differential of the pressure

switch between the start and stop

pressures is too small.

Increase the differential. However, the stop

pressure must not exceed the operating

pressure of the pressure tank, and the start

pressure should be high enough to ensure

sufficient water supply.

b) The water level electrodes or level

switches in the reservoir have not

been installed correctly.

Adjust the intervals of the electrodes/level

switches to ensure suitable time between

the cutting-in and cutting-out of the pump.

See installation and operating instructions

for the automatic devices used. If the

intervals between stop/start cannot be

changed via the automatics, the pump

capacity may be reduced by throttling the

discharge valve.

c) The non-return valve is leaking or

stuck half-open.

Pull out the pump and clean/replace the

non-return valve.

d) The supply voltage is unstable. Check the electricity supply.

e) The motor temperature gets too

high.

Check the water temperature.

Fault Cause Remedy

TM02 0689 5000

Loading...

Loading...