Pump control in heating systems

The heating required in a building varies greatly during the

day due to changing outdoor temperatures, solar radiation

and heat emanating from people, electric appliances, and

others. In addition, the need for heating may vary from

one section of the building to another and the thermostatic

valves of some radiators may have been turned down by

the users. An uncontrolled pump will produce a too high

differential pressure when the heat demand and flow are

low.

Possible consequences:

• too high energy consumption

• irregular control of the system

• noise in thermostatic radiator valves and similar

fittings.

Grundfos UPM3 HYBRID and UPM3 AUTO automatically

control the differential pressure by adjusting the pump

performance to the actual heat demand, without the use

of external components.

Advantages of pump control

In Grundfos UPM3 HYBRID and UPM3 AUTO pump

control is effected by adapting the differential pressure to

the flow (proportional-pressure and constant-pressure

control). Contrary to an uncontrolled pump, a constant-

pressure-controlled pump keeps the differential pressure

constant. A proportional-pressure-controlled pump

reduces the differential pressure as a result of falling heat

demand.

For example:

If the heat demand falls, for instance, due to solar

radiation, the thermostatic radiator valves will close, and,

for the uncontrolled pump, the flow resistance of the

system will rise, for instance from A1 to A2.

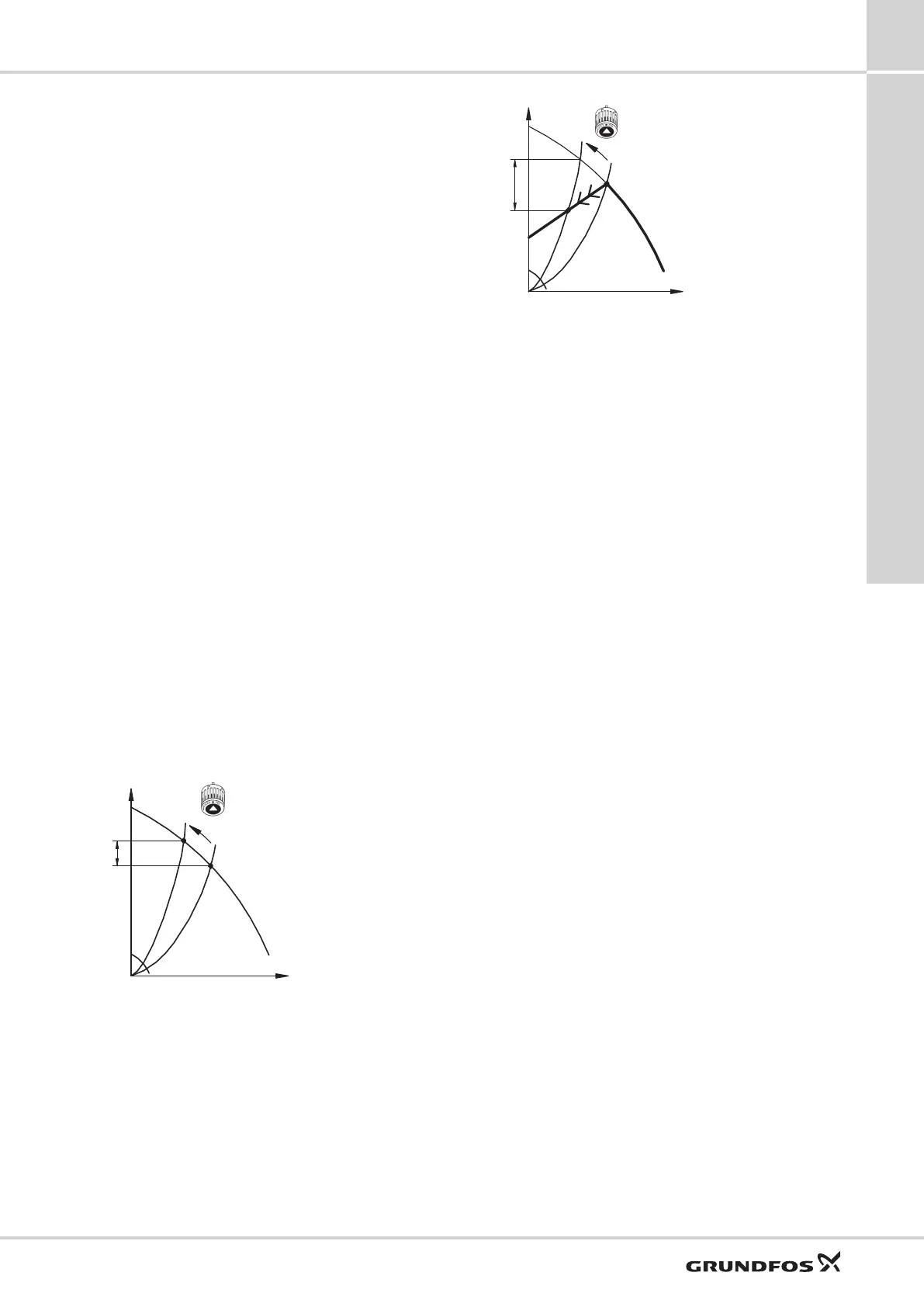

In a heating system with an uncontrolled pump, this

situation will cause a pressure rise in the system by ΔH

1

.

TM060857

Uncontrolled pump

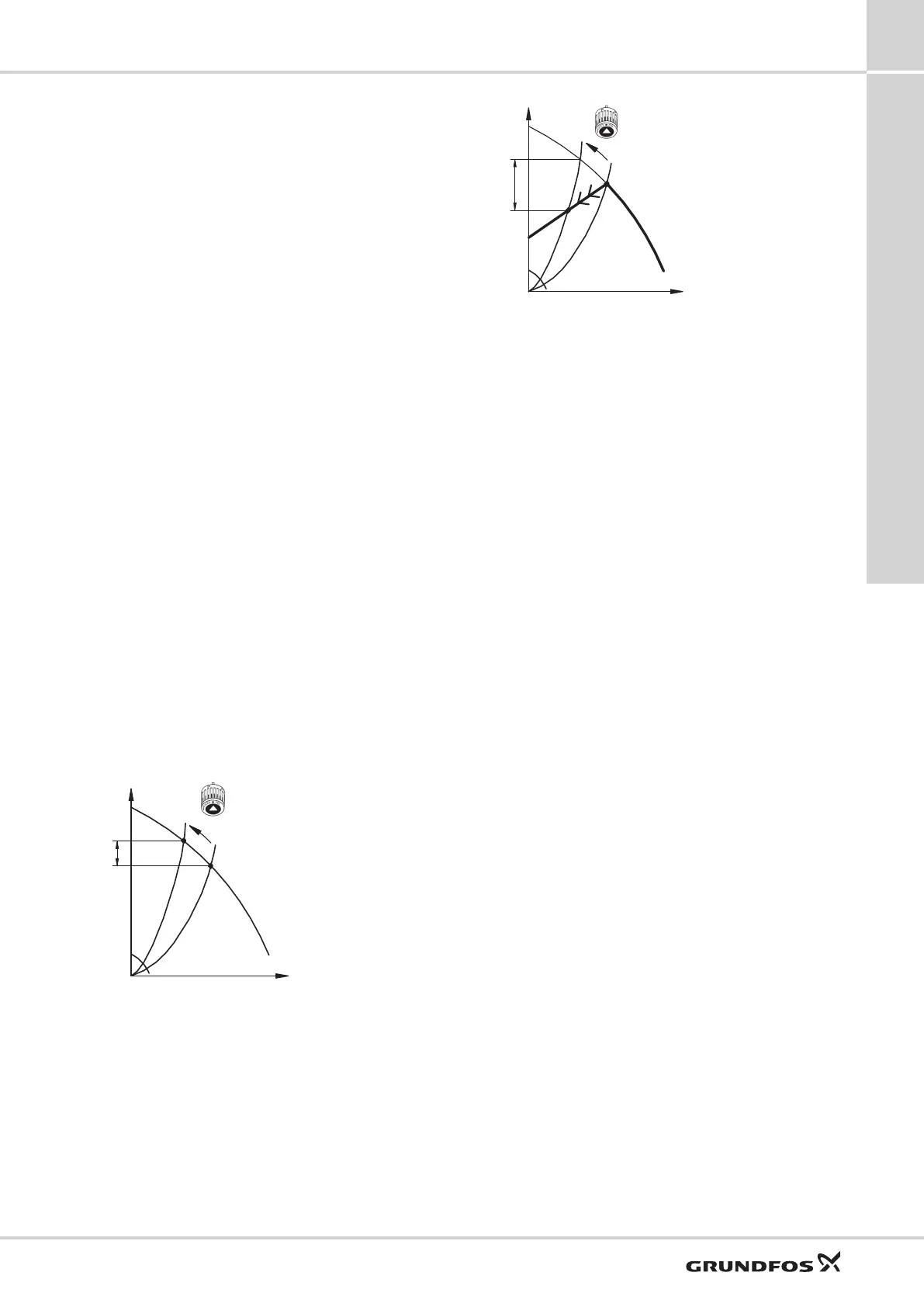

In a system with a proportional-pressure-controlled pump,

operated in the proportional pressure mode the pressure

will be reduced by ΔH

2

and result in reduced energy

consumption.

TM060858

Pump operated in proportional-pressure control mode

In a system with an uncontrolled pump, a pressure rise

will often cause flow-generated noise in the thermostatic

radiator valves. This noise will be reduced considerably

with proportional pressure control.

AUTO

ADAPT

Grundfos holds a patent for AUTO

ADAPT

since 1995. With

AUTO

ADAPT

, the control curve is automatically adapted to

the actual requirements of the respective application.

If you select AUTO

ADAPT

, the pump starts with the

medium proportional or constant control curve and runs

on this curve as long as a new curve will be adapted.

The AUTO

ADAPT

proportional pressure functionality is well

known from millions of installed Grundfos trade pumps as

ALPHA2 or MAGNA. The AUTO

ADAPT

setting continually

analyses and finds the setting where optimal comfort

meets minimal energy consumption. It automatically

delivers perfect comfort at the lowest possible energy

level. It adapts to the requirements of the heating system

before reaching the maximum pump curve and allows the

pump to adjust the proportional pressure or constant

pressure curve both up and down.

Advantages of AUTO

ADAPT

• Easy installation

• Automatic setting

• Demand-controlled operations

• Optimum comfort

• Energy savings

• Reduced CO

2

emissions.

Constant pressure at all load conditions is essential for

how well the thermostatic valves can control the heat

emission from the radiators. It is a well-known fact that

optimum pump control in a two-pipe heating system with

thermostatic radiator valves is best obtained by controlling

pump pressure on a proportional pressure curve. In

under-floor heating or one-pipe systems it might be better

to use constant pressure control. However, predicting the

best position in real-life applications is rather difficult,

because the optimum position depends on correlated

factors such as the size of the heating system, the boiler

type, the load condition, etc. This is where AUTO

ADAPT

steps in to ensure that the pump is controlled in an

optimum manner.

UPM3

8

31

Control modes, operating panel and settings

Loading...

Loading...