7. External control mode and signals

Control principles

The UPM3 and UPM3 FLEX pumps are controlled via a

digital low-voltage pulse-width modulation (PWM) signal

which means that the speed of rotation depends on the

input signal.

UPM3 HYBRID pumps can be set to either internally or

externally controlled. The speed changes as a function of

the input profile. These communication signals are

standardised in the VDMA Einheitsblatt 24244 "Wet

runner circulating pumps - Specification of PWM control

signals".

Control signals

Digital low-voltage PWM signal

The square-wave PWM signal is designed for a 100 to

4,000 Hz frequency range. The PWM signal is used to

select the speed (speed command) and as feedback

signal. The PWM frequency on the feedback signal is

fixed at 75 Hz in the pump.

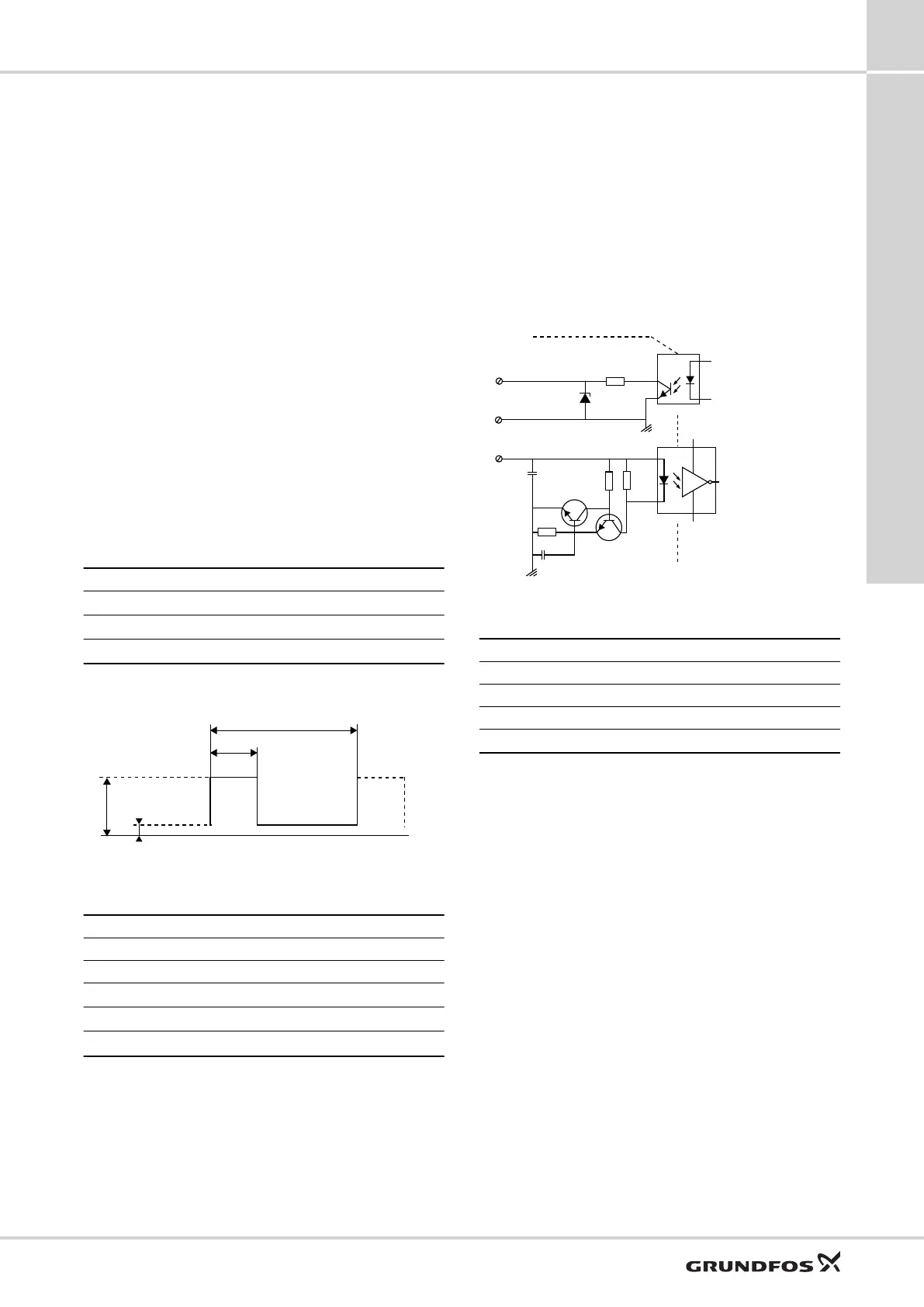

Duty cycle

d % = 100 x t/T

Example Rating

T = 2 ms (500 Hz)

U

IH

= 4-24 V

t = 0.6 ms

U

IL

≤ 1 V

d % = 100 x 0.6 / 2 = 30 %

I

IH

≤ 10 mA (depending on U

IH

)

Example

TM049911

PWM signal

Abbreviation Description

T Period of time [sec.]

d Duty cycle [t/T]

U

IH

High-level input voltage

U

IL

Low-level input voltage

I

IH

High-level input current

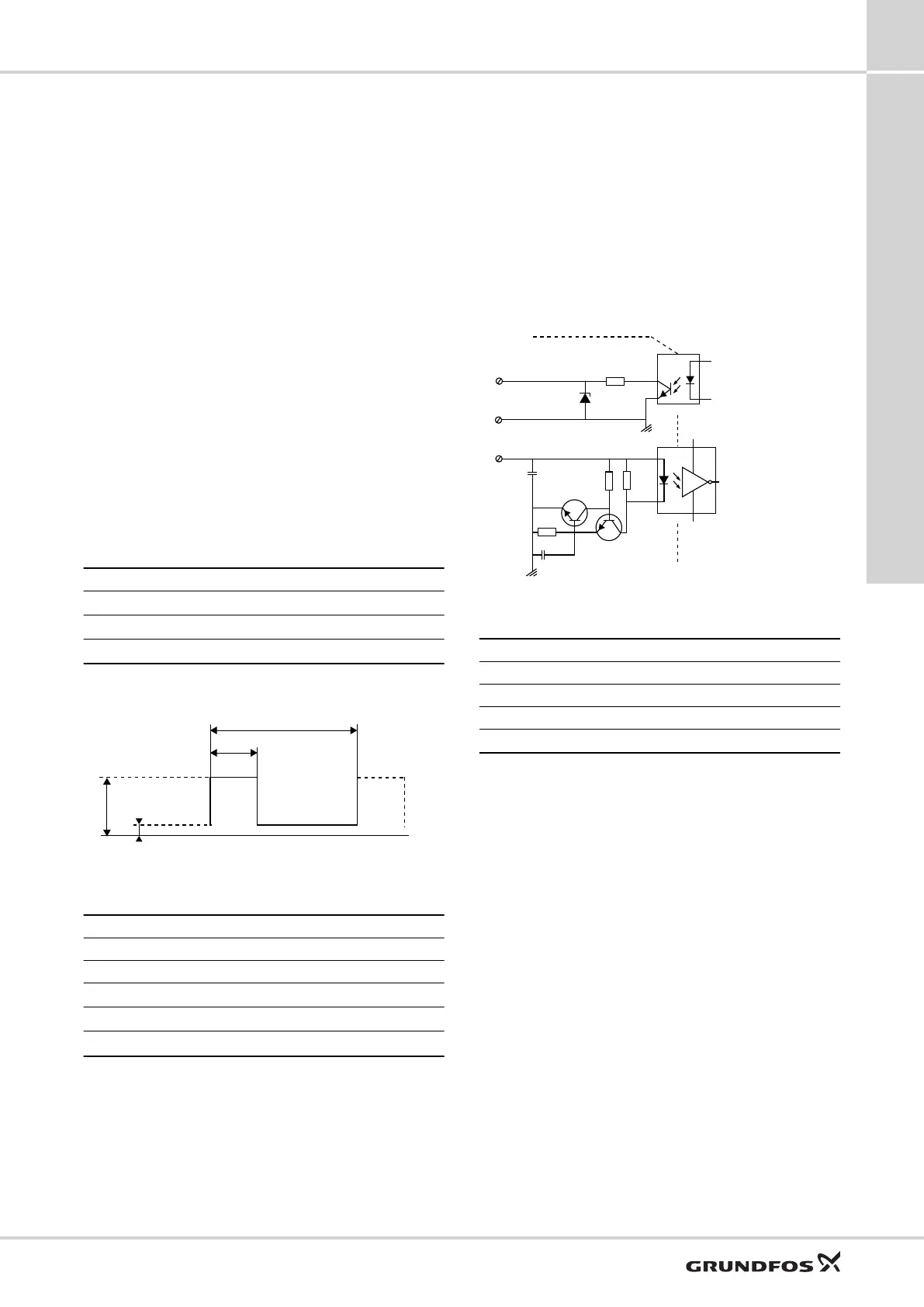

PWM interface

The PWM interface consists of an electronic part

connecting the external control signal to the pump. The

interface translates the external signal into a signal type

that the microprocessor can understand.

In addition, the interface ensures that the user cannot get

into contact with dangerous voltage if touching the signal

wires when power is connected to the pump.

470R

36V

100p

110R

BC847B

BC847B

TLP2704

TLP383

68k

2k7

+

-

1

2

3

4

TM060787

Schematic drawing, interface

Pos. Description

1 Galvanic isolation

2 PWM output

3 Signal reference (without connection to protective earth)

4 PWM input

Related information

UPM3

UPM3

7

17

External control mode and signals

Loading...

Loading...