56

Smart Power

(1)

(a)

(b)

(2)

(3)

(4)

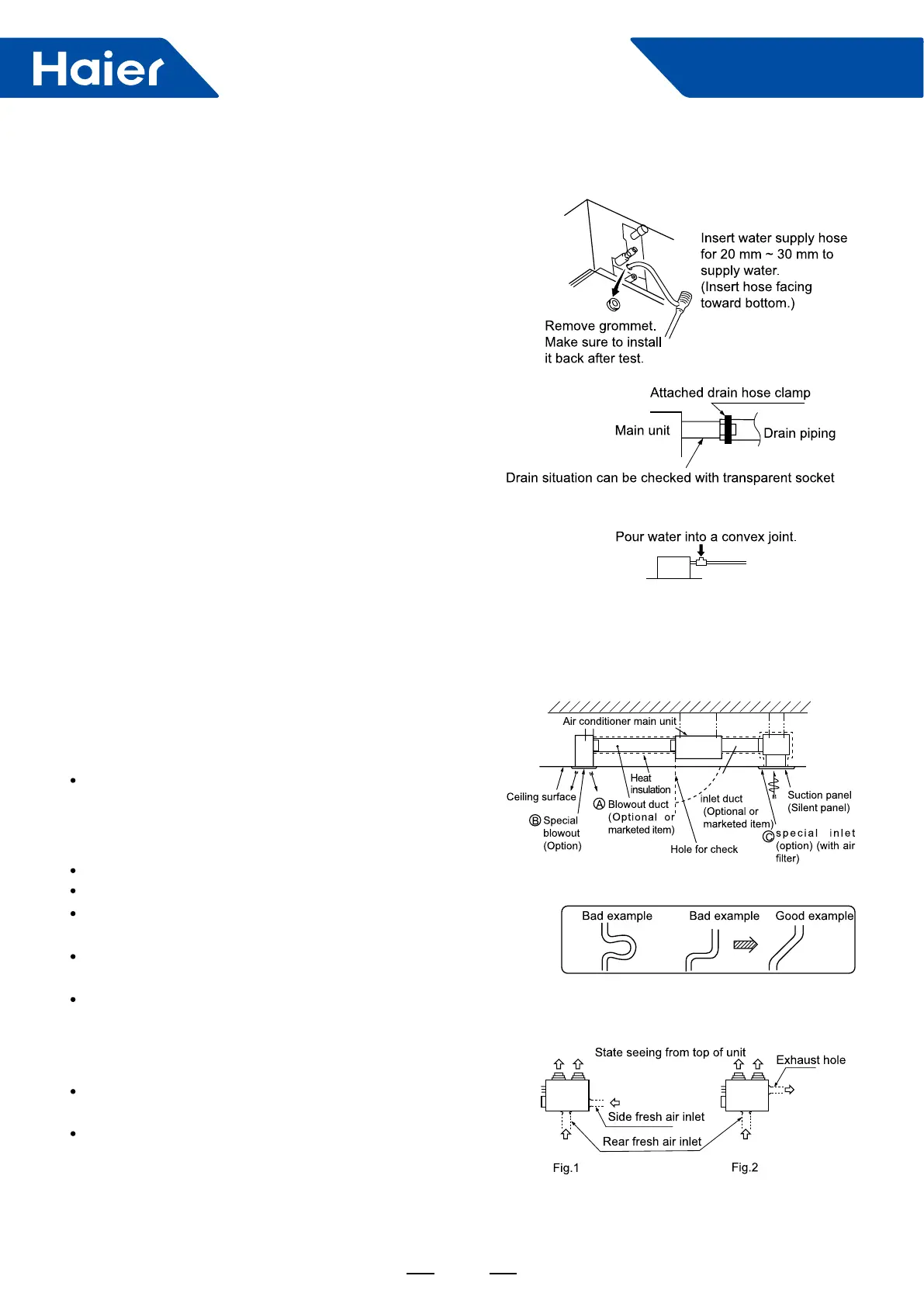

Conduct a drainage test after completion of the electrical

work.

During the trial, make sure that drain ows properly

through the piping and that no water leaks from

connections.

In case of a new building, conduct the test before it is

furnished with the ceiling.

Be sure to conduct this test even when the unit is installed

in the heating season.

Supply about 1000 cc of water to the unit through the air

outlet using a feed water pump.

Check the drain while cooling operation.

Before the electrical work has not been completed, connect

a convex joint in the drain pipe connection to provide a water

inlet. Then, check if water leaks from the piping system and

that drain ows through the drain pipe normally.

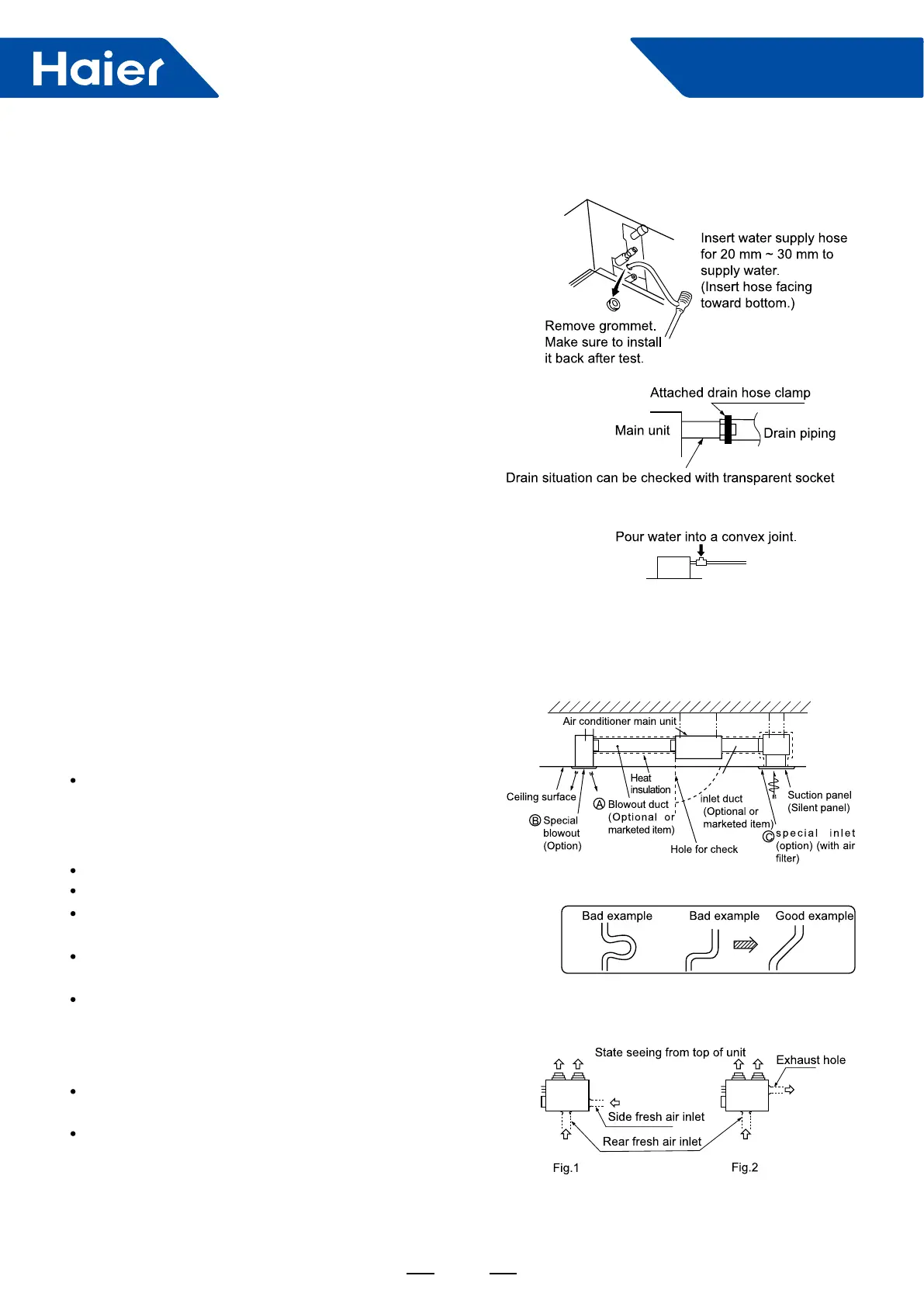

Calculate the draft and external static pressure and select

the length, shape and blowout.

Note (1) Shield the central blowout hole for 2-spot.

(2) Shield the blowout hole around the center for 3-spot.

2-spot, 3-spot and 4-spot with φ 200 type duct are the

standard specications.

Inlet can be selected from the side or rear faces depending

on the working conditions.

Use the rear fresh air inlet when the simultaneous intake

and exhaust is conducted. (Side inlet cannot be used.)

Use the side exhaust port.

Limit the difference in length between spots at less than 2:1.

Reduce the length of duct as much as possible.

Reduce the number of bends as much as possible. (Corner

R should be as larger as possible.)

Use a band. etc. to connect the main unit and the blowout

duct ange.

Conduct the duct installation work before nishing the

ceiling.

A Blowout duct

Drainage Test

Procedures

Installation work for air outlet ducts

Connection of suction, exhaust ducts

a.Fresh air inlet

b.Exhaust (Make sure to use also the suction.)

Loading...

Loading...