6

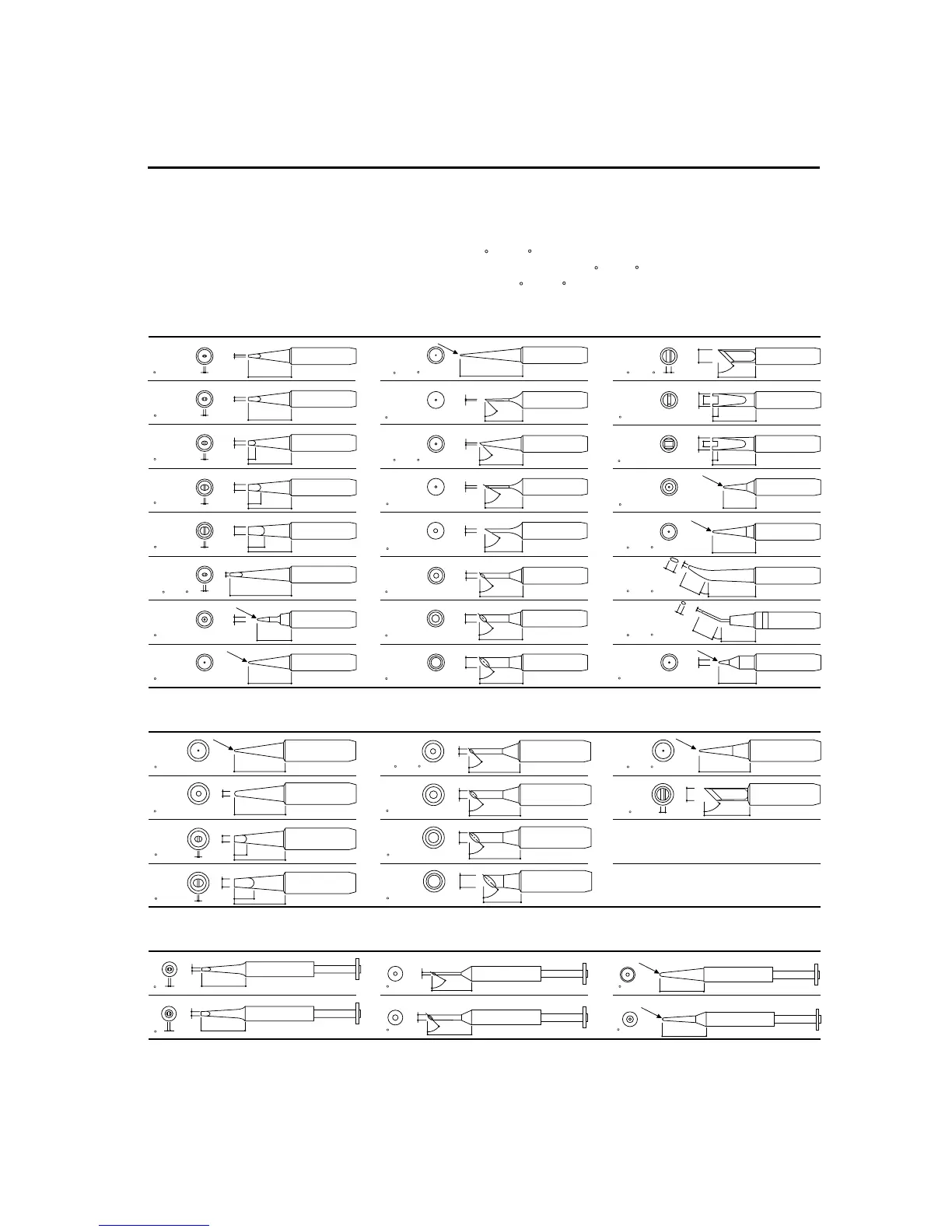

The tip temperature will vary according to the shape of the tip. The preferred method of adjustment uses a tip

thermometer. (See “Calibrating the Iron Temperature” on page 5.)

A less accurate method involves adjusting the temperature control knob according to the adjustment value for each tip.

Example : When using a 900M-T-H tip at 400 C (750 F),

the difference between this tip and a 900M-T-B is -20 C (-36 F).

Set the temperature control knob to 420 C (786 F).

Refer to the chart for the correct adjustment values.

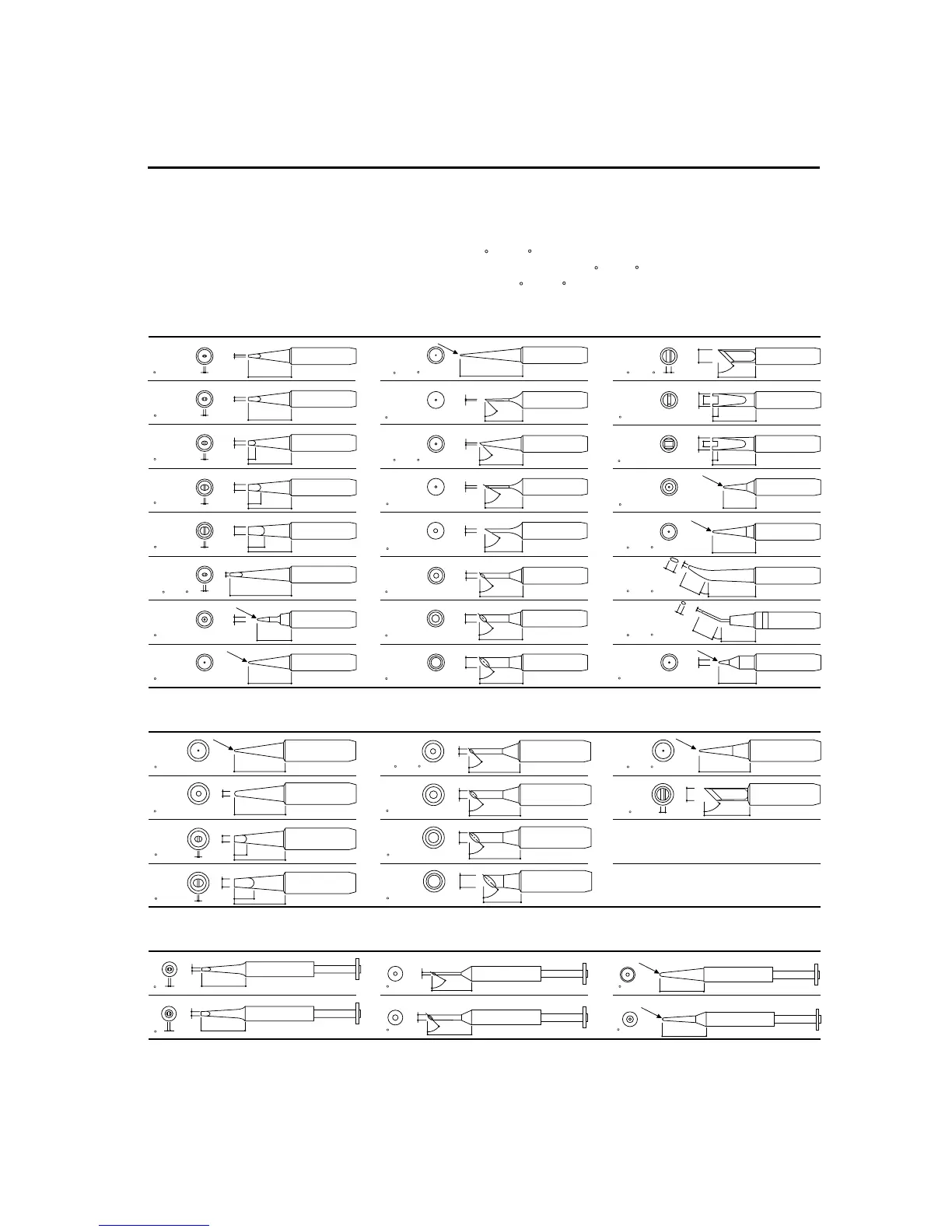

Tips

17(0.66)

(0.25)

6.5

(0.12)

ø3.2

0.5(0.02)

900M-T-3.2D

17(0.66)

900M-T-B

R0.5(0.02)

25(0.98)

900M-T-LB

R0.2(0.008)

15(0.6)

(0.04)

ø1

900M-T-1C

900M-T-1CF*

60

17(0.66)

(0.08)

ø2

900M-T-2C

900M-T-2CF*

45

17(0.66)

(0.1)

ø3

900M-T-3C

900M-T-3CF*

45

15(0.6)

(0.2)

ø5

2(0.08)

900M-T-K

45º

17(0.66)

(0.08)

2

(0.17)

ø4.2

900M-T-RT

(0.08)

2

17(0.66)

(0.08)

2

(0.2)

ø5.1

900M-T-R

(0.1)

3.2

17(0.66)

900M-T-I

R0.2(0.008)

19(0.74)

900M-T-H

25

(0.29)

7.5

1.2(0.04)

3.5(0.13)

14(0.55)

900M-T-1.8H

25

(0.29)

7.5

1(0.04)

1.8(0.07)

15(0.6)

900M-T-S4

R0.25(0.01)

(0.08)

ø2

17(0.66)

(0.031)

ø0.8

0.6(0.024)

900M-T-0.8D

17(0.66)

(0.047)

ø1.2

0.7(0.028)

900M-T-1.2D

25(0.98)

(0.047)

ø1.2

0.7(0.028)

900M-T-1.2LD

15(0.6)

(0.02)

ø0.5

900M-T-0.5C

45

17(0.66)

(0.031)

ø0.8

900M-T-0.8C

45

15(0.6)

(0.06)

ø1.5

900M-T-1.5CF*

60

14(0.55)

900M-T-SB

R0.2(0.008)

(0.08)

ø2

13(0.51)

900M-T-SI

R0.2(0.008)

17(0.66)

(0.16)

ø4

900M-T-4C

900M-T-4CF*

45

20(0.8)

900L-T-B

R0.5(0.02)

20(0.8)

900L-T-2B

(0.08)

ø2

20(0.8)

900L-T-2.4D

(0.09)

ø2.4

5

(0.2)

0.5(0.02)

20(0.8)

900L-T-3.2D

(0.12)

ø3.2

8(0.3)

0.5(0.02)

20(0.8)

900L-T-2C

900L-T-2CF*

(0.08)

ø2

45

20(0.8)

900L-T-3C

900L-T-3CF*

(0.1)

ø3

45

20(0.8)

900L-T-4C

900L-T-4CF*

(0.15)

ø4

45

15(0.6)

900L-T-5C

900L-T-5CF*

(0.2)

ø5

45

20(0.8)

900L-T-I

R0.2(0.008)

18(0.7)

900L-T-K

(0.2)

ø5

2(0.08)

45

0.4(0.016)

17(0.66)

(0.047)

ø1.2

900S-T-1.2D

0.5(0.02)

17(0.66)

(0.06)

ø1.6

900S-T-1.6D

17(0.66)

(0.08)

ø2

900S-T-2C

45

15(0.6)

(0.04)

ø1

900S-T-1C

60

17(0.66)

900S-T-B

R0.5(0.02)

17(0.66)

900S-T-I

R0.2(0.008)

907

0 C

0 C

0 C

-10 C/-18 F

0 C

0 C

0 C

0 C

-10 C/-18 F

0 C

-10 C/-18 F

0 C

0 C

0 C

0 C

0 C

+30 C/+54 F

0 C

0 C

0 C

0 C

-10 C/-18 F

-20 C/-36 F

-10 C/-18 F

0 C

0 C

0 C

0 C

-20 C/-36 F

0 C

0 C

0 C

-20 C/-36 F

+20 C/

+36 F

0 C

0 C

0 C

0 C

0 C

0 C

908

900S

17(0.66)

5

(0.09)

ø2.4

0.5(0.02)

900M-T-2.4D

(0.2)

17(0.66)

3

(0.06)

ø1.6

0.5(0.02)

900M-T-1.6D

(0.1)

•900S Tip Out Diam ø5.8

For micro soldering HAKKO recommends the 900S iron with fine tips.

For heavy duty soldering HAKKO recommends the 908 iron with heavier tips.

•900L tip Out Diam ø8.5

*-These tips are tinned flat only.

•900M tip Out Diam ø6.5

Loading...

Loading...