Do you have a question about the Hakko Electronics FX-888D and is the answer not in the manual?

Instructions for preparing the iron holder with sponge and water.

Steps for connecting the soldering iron to the station and plugging in the power.

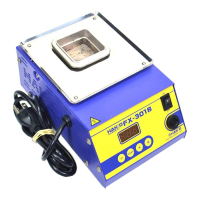

Details the switch and control buttons on the front panel and their functions.

Procedure for turning on the power and initial display indications.

Instructions for cleaning and coating the tip after use.

Guides on how to change temperature settings in normal and preset modes.

Process for adjusting the tip temperature using Adjustment Mode.

Explains how to restrict setting changes using a password and the procedure.

Procedure to enter parameter setting mode by pressing the UP button during power-on.

How to switch the temperature display between Celsius and Fahrenheit.

Setting the low-limit temperature to trigger an error display.

Switching between normal and preset temperature setting modes.

Detailed steps for configuring password protection for various settings.

Procedures for cleaning, re-tinning, and replacing the soldering iron tip.

Tests to check for a broken heating element or sensor by measuring resistance.

Methods to test the cord assembly for damage or breakage.

| Power Consumption | 70W |

|---|---|

| Heating Element | Ceramic |

| Tip to Ground Potential | < 2 mV |

| Tip to Ground Resistance | <2Ω |

| Certifications | CE, RoHS |

| Temperature Stability | ±1°C (±2°F) at idle temperature |

| Weight | 1.1 kg |

| Output Voltage | 24V |

Loading...

Loading...