4. Operation

(cont'd)

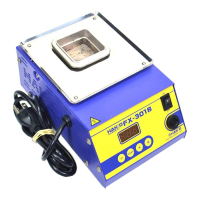

4-3. Operation

CAUTION

●

Keep the solder pot cover closed until the solder is fully melted.

●

The solder pot cover is very hot. Do not touch anything other than the front section of the frame.

(1)

Turn the power on.

(2)

Below shows what is displayed.

(3)

Once the set temperature is reached, open the solder pot cover when ready to use.

(4)

Keep the solder pot cover closed when not in use.

Lock icon

Temperature

icon

Offset icon

Timer icon

Communication Communication

iconicon

Setting

temperature

Temperature

Correction mode

Temperature

Setting Mode

Preset icon

Pot sensor

temperature

Parameter

icon

Up

button

Down

button

Confirm

button

Back

button

Stop Mode

Operation

button

Preset No.

Mode

■

Changing the temperature setting

Push

Push this button once to display [ ] and transition to "temperature setting mode."

This mode is used when changing the set temperature.

Push once

[

] and [ ]

disappear.

Temperature

control begins

Normal screen

To change to 400ºC

Push five times

Push Push Push

Once the normal screen appears, push the button to transition to preset No. mode.

■

Changing the preset No.

You can register up to ve frequently used setting temperatures on the product, and then select the

registration No. to change the setting temperature.

Push

Push this button once to transition to "preset No. mode."

Select one of the ve temperatures registered in this mode.

( Factory default temperature settings: P1 250ºC (600ºF), P2 300ºC (700ºF), P3 350ºC (750ºF),

P4 400ºC (800ºF), P5 450ºC (850ºF))

NOTE

The registered temperature of each preset No. can be changed in "parameter No.

."

(See the separate document "Quick Parameter Settings")

NOTE

If you want to limit setting temperature changes, change the setting in "parameter No.

."

(See the separate document "Quick Parameter Settings")

■

Internal pot temperature correction (oset)

Push

Push this button once to display [ ] and transition to "temperature correction mode." If the

setting temperature and measured value of the internal pot temperature dier in this mode, you

can correct the temperature.

(Correction range: ±100ºC/±180ºF)

Push five times

[

] disappears.

Normal screen

To correct a temperature by 5ºC for a setting of 400ºC

(to correct actual internal pot temperature reading 395ºC when set to 400ºC)

0 to 9

(ºF: 0 to 8)

–/0

* Note that temperatures that exceed the correction range cannot be entered.

0 to 9

0 to 1

Temperature sending screen

The internal pot temperature can change if it contains too many

impurities. The internal pot temperature changes if you replace the

pot, so the oset will need to be readjusted. Make sure to change

the oset value as needed while monitoring the actual internal pot

temperature.

You can automatically change the oset value using a HAKKO

thermometer with a temperature sending function. Push the

button before sending the measured value. (See the gure on the

right)

The communication icon is

only displayed at this state.

Push Push Push Push Push Push

Temperature

control begins

■

Checking the drop in temperature inside the pot (Stop mode: Heating element o)

Push

Push this button once to display the conrmation screen, then push the button to conrm.

This will turn o the heating elements and is used to show the pot temperature cooling to a safe

level. Push the

button again to turn the heaters on and return to normal operation.

Confirmation screen Dropped to room temperature

Turn o the power. Replace the pot.

Push

Push the button once to check the "solder type" and "accumulated pot usage time" set in the parameters.

(See the separate document "Quick Parameter Settings")

Setting temperature Solder type Accumulated pot usage time

This is displayed if you select [ON]

in Parameter No.

.

Use this to estimate the pot

replacement schedule.

5,460 hours

(546 × 10 hours = 5,460)

Loops for one minute until you push the button.

5. Parameter Settings

You can change the parameter settings to suit dierent work environments. See the separate document

"Quick Parameter Settings."

6. Maintenance

CAUTION

Use with caution, this product get hot during use.

Conducting maintenance will help keep the product in good condition and prolong the usage of the unit.

■

Daily maintenance

Wear and tear on the pot will vary due to the operating temperature as well as the quality and amount of

solder used. Maintenance should be performed based on what suits your usage.

Setting

temperature

Using the product at a temperature that is higher than necessary can accelerate pot

deterioration and damage parts that are susceptible to heat. Use lowest temperature

whenever possible.

Before

beginning

work

●

Pot

When cool, remove the pot and visually check the following:

・

Are there any holes in the pot?

・

Has any solder leaked onto the heat

insulation plate?

・

Has any foreign matter collected on the heat

insulation plate?

Make sure to change the orientation of the pot

each time you remove it. Doing so can slow

pot deterioration.

●

Solder pot cover

Remove any solder stuck to the cover. Doing

so can prevent any solder from unintentionally

falling into the pot. Make sure to do so when

changing the solder type.

When pausing

work

Turn o the unit for long periods of unused time.

●

Solder

Remove any oxidation or foreign matter in the molten solder using the spatula.

7. Troubleshooting

CAUTION

Before performing an inspection or replacing parts, make sure to disconnect the power plug from the outlet.

No operation even if

power switch is turned

ON.

Is the power cord connected?

Connect the power cord to the main

unit.

Is the fuse blown?

Replace the fuse.

If the fuse is blown again, send the

main unit back for service.

[L - E] is displayed.

Is there any foreign matter on

the heat insulation plate located

under the pot?

Remove/clean any foreign matter.

Is there any holes in the pot and

has solder leaked into the interior

of the main unit?

Remove the solder and replace the pot.

[S - E] is displayed.

Is the heating element connected

to the board?

Connect it to the board.

The internal pot

temperature is too high/

low.

Is the oset value entered

correct?

Measure and adjust the value.

(See "

■

Internal pot temperature

correction (oset)" in "4-3. Operation")

Is one of the heating elements

burnt out?

If the resistance of the heating element

is abnormal, replace it.

(See "How to check the heating element

resistance")

Is the heating element connected

to the board?

Connect it to the board.

If you cannot nd a solution in this manual, or if another problem occurs, please contact the retailer

where you purchased the product.

How to check the heating element resistance

(1)

Disconnect the power plug from the outlet.

(2)

Remove the pot when it is cool.

(3)

Remove the screws and washer securing the cover.

(4)

Open the cover.

(5)

Disconnect the heating element connector from

the board.

(6)

Measure the resistance of the heating element

when it is at room temperature.

(See below for pin layout and resistance

references)

(7)

Replace the heating element if the value is

abnormal.

Pot

Heat insulation plate

1 3

1 3 56

Heating element

right side

Heating element

left side

Between pins 1 - 3 Between pins 5 - 6

100 V / 110 V 8 to 13 Ω

129 to 191 Ω120 V 13 to 18 Ω

220 V / 230 V / 240 V 46 to 63 Ω

Normal resistance for

heating element left side

(at room temperature)

Normal resistance for

heating element right side

(at room temperature)

Between pins 1 - 3

100 V / 110 V 5 to 9 Ω

120 V 9 to 12 Ω

220 V / 230 V / 240 V 31 to 42 Ω

Cover

Washer

Screw

Loading...

Loading...