32

Required Parts

• Elevator joiner wire • CA hinge (6)

• Fuselage assembly

• Elevator (left and right)

Required Tools and Adhesives

• Thin CA • T-Pins

• 30-minute epoxy • Medium sandpaper

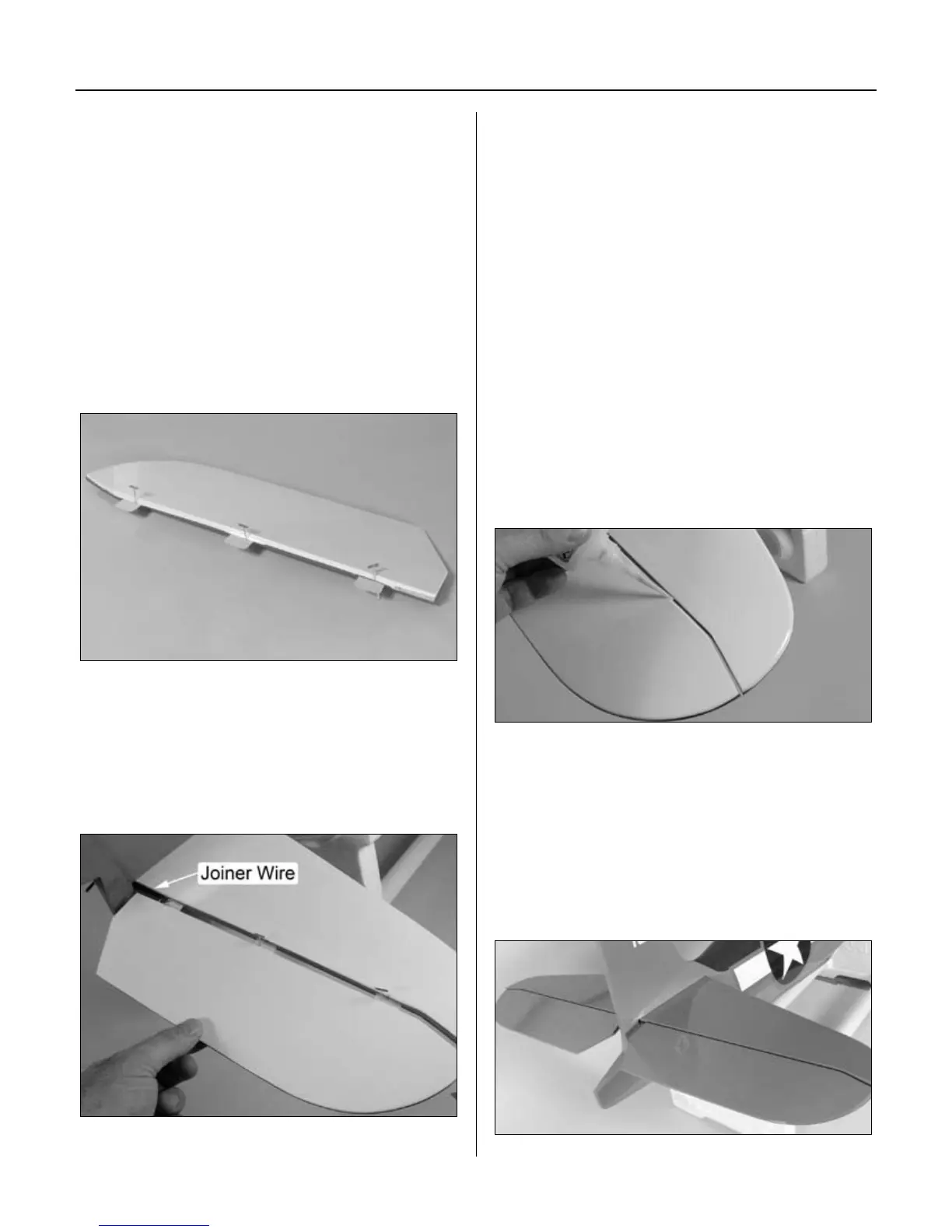

Step 1

Remove the covering from the slot in the elevator.

Locate three CA hinges. Place a T-pin in the center of

the hinges. Place the hinges into the elevator half.

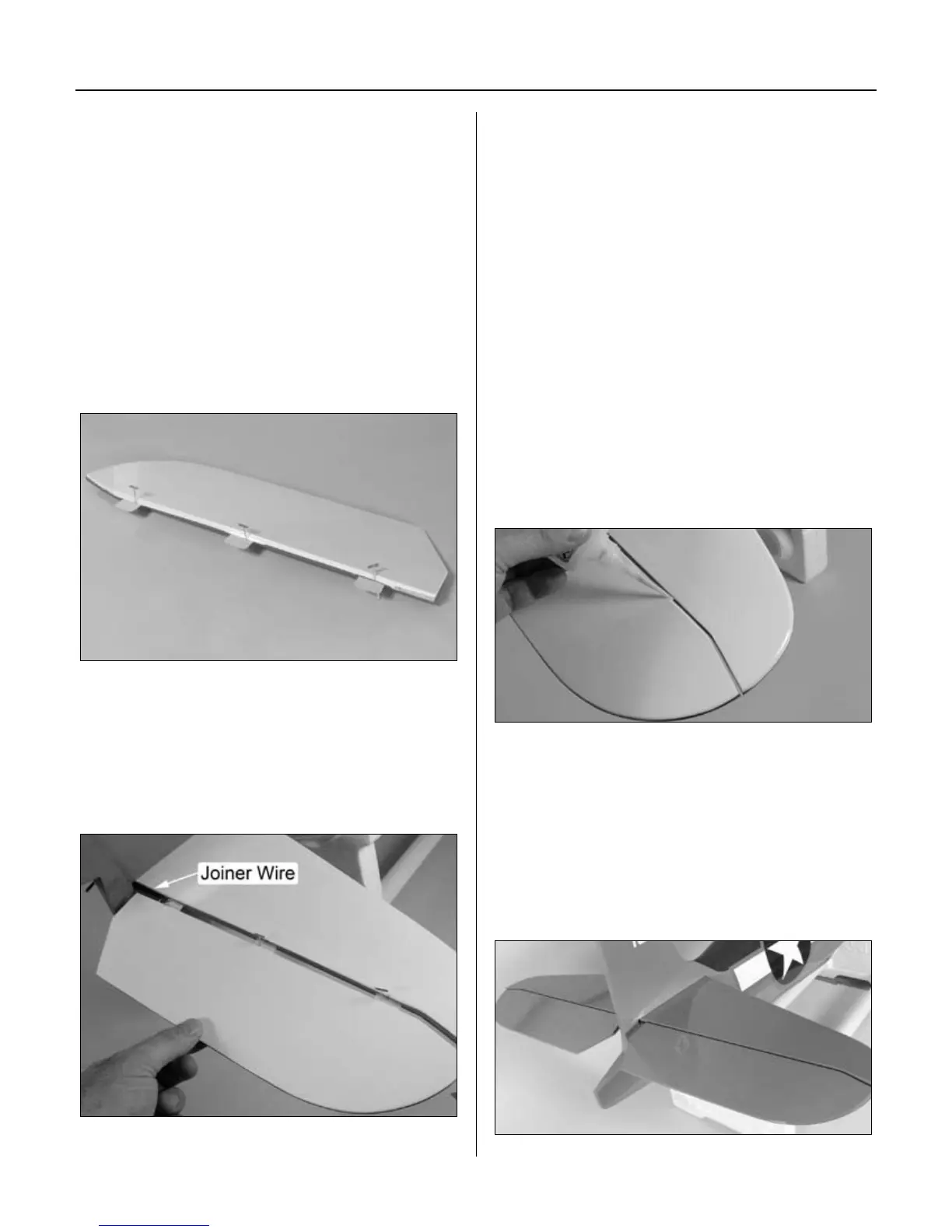

Step 2

Lightly sand the elevator joiner wire. Clean the wire

using a paper towel and rubbing alcohol. Slide

the elevator joiner wire into position. Test fit the

elevator and stab together. The elevator joiner wire

will be inserted into the hole exposed in Step 1.

Step 3

Mix 1/2 ounce of 30-minute epoxy and apply it to the

groove and hole in the elevator half. Insert the elevator

joiner wire. Press the elevator against the stabilizer so

that the hinge gap between the elevator and stabilizer is

roughly 1/64" (.4mm). Remove the T-pins and remove any

excess epoxy using rubbing alcohol and a paper towel.

Note: You can combine the previous step with

the following step if you like. This will hold

the elevator in position while the epoxy cures.

Step 4

Line up the tip of the elevator with the stabilizer tip.

Again, check to make sure the hinge gap between

the elevator and stabilizer is roughly 1/64" (.4mm).

Apply thin CA to both sides of the hinge. Make sure

to saturate the hinge and don’t use accelerator.

Step 5

Once the CA and epoxy have fully cured, gently pull on the

elevator and stab to make sure the hinges are well glued.

Flex the elevators a few times to break in the hinges.

Step 6

Repeat Steps 1 through 5 to install the remaining

elevator half.

Section 8: Installing the Elevators

Loading...

Loading...