6

E

N

G

L

I

S

H

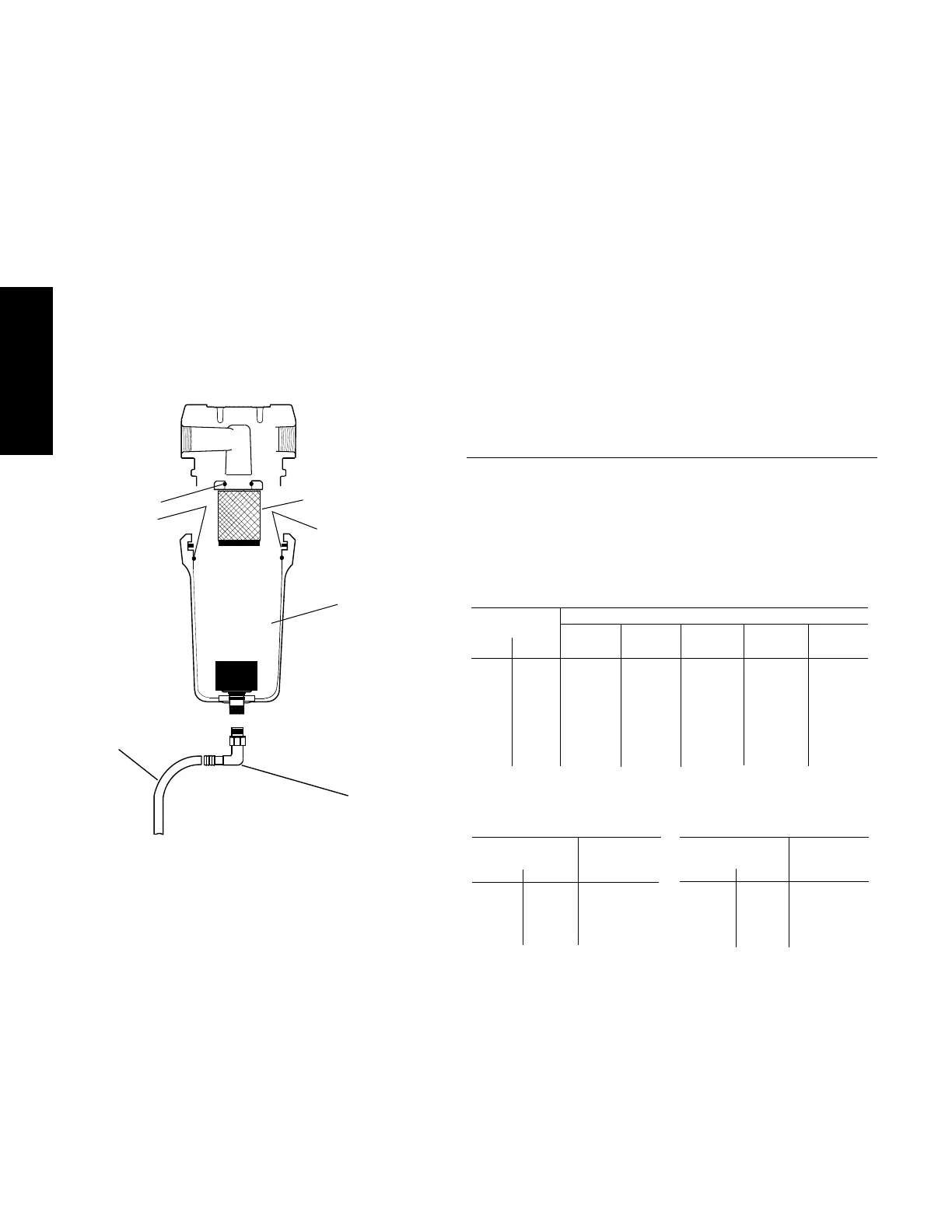

OUTLET DEWPOINT

DEW POINT

TEMPERATURE MULTIPLIER

°F °C

38 3 1.0

40 4 1.1

45 7 1.2

50 10 1.3

COOLING MEDIUM*

AMBIENT

TEMPERATURE MULTIPLIER

°F °C

80 27 1.12

90 32 1.06

100 38 1.00

110 43 0.94

INLET COMPRESSED AIR CONDITIONS

INLET INLET TEMPERATURES

PRESSURES 80

°F90°F 100°F 110°F 120°F

psig kgf/cm

2

27°C32°C38°C 43°C49°C

50 3.5 1.35 1.05 0.84 0.69 0.56

80 5.6 1.50 1.17 0.95 0.79 0.66

100 7.0 1.55 1.23 1.00 0.82 0.70

125 8.8 1.63 1.31 1.07 0.91 0.74

150 10.5 1.70 1.37 1.13 0.95 0.80

175 12.3 1.75 1.42 1.18 0.99 0.84

200 14.0 1.80 1.47 1.22 1.03 0.89

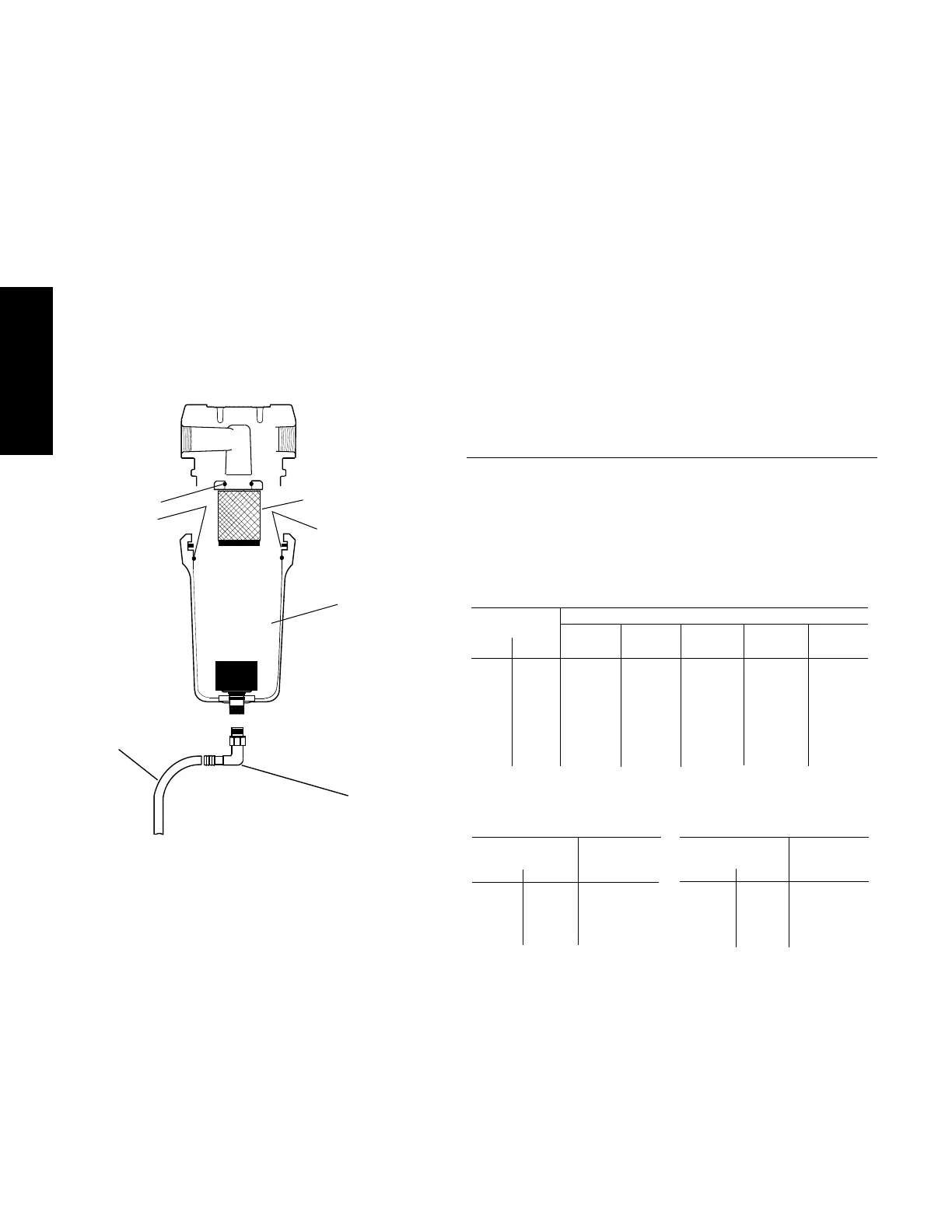

3.1 Condenser coil—

Clean off accumulated dust and dirt monthly.

3.2 Moisture separator—

Replace filter element when pressure drop across

dryer is excessive or annually.

3.3 Check separator daily to be sure automatic drain is

discharging.

3.4 Replace drain mechanism annually.

To facilitate service, maintenance kits are available.

3.0 Maintenance Sizing

Determining dryer capacity at actual operating

conditions

To determine the maximum inlet flow capacity of a dryer

at various operating conditions, multiply the rated

capacity from Table 1 by the multipliers shown in Table 2.

Example: How many scfm can an air-cooled model 125

handle when compressed air to be dried is at 80 psig and

90°F; ambient air temperature is 80°F; and a 35°F dew

point temperature is desired?

Answer: 125 x 1.17 x 1.12 x 1.0 = 163.8 scfm.

TABLE 2

Air capacity correction factors (Multipliers)

25 35 50 75 100 125 150

MODEL

Rated capacity of 60 Hz 25 35 50 75 100 125 150

air-cooled models (scfm) 50 Hz 21 29 42 63 84 105 125

TABLE 1

Rated capacity (scfm) and pressure drop @ 100 psig inlet

pressure, 100°F inlet temperature, and 100°F ambient

temperature

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling water is

below 35°C, 95°F.

Element o-ring

Separator Element

Bowl o-ring

Drain Mechanis

Wave Spring

Tube

Hose

Barb

Loading...

Loading...