GB 04 02 MA

Description

Unloading the sprUnloading the spr

Unloading the sprUnloading the spr

Unloading the spr

aa

aa

a

yy

yy

y

er frer fr

er frer fr

er fr

om the trom the tr

om the trom the tr

om the tr

ucuc

ucuc

uc

kk

kk

k

Lifting pointsLifting points

Lifting pointsLifting points

Lifting points

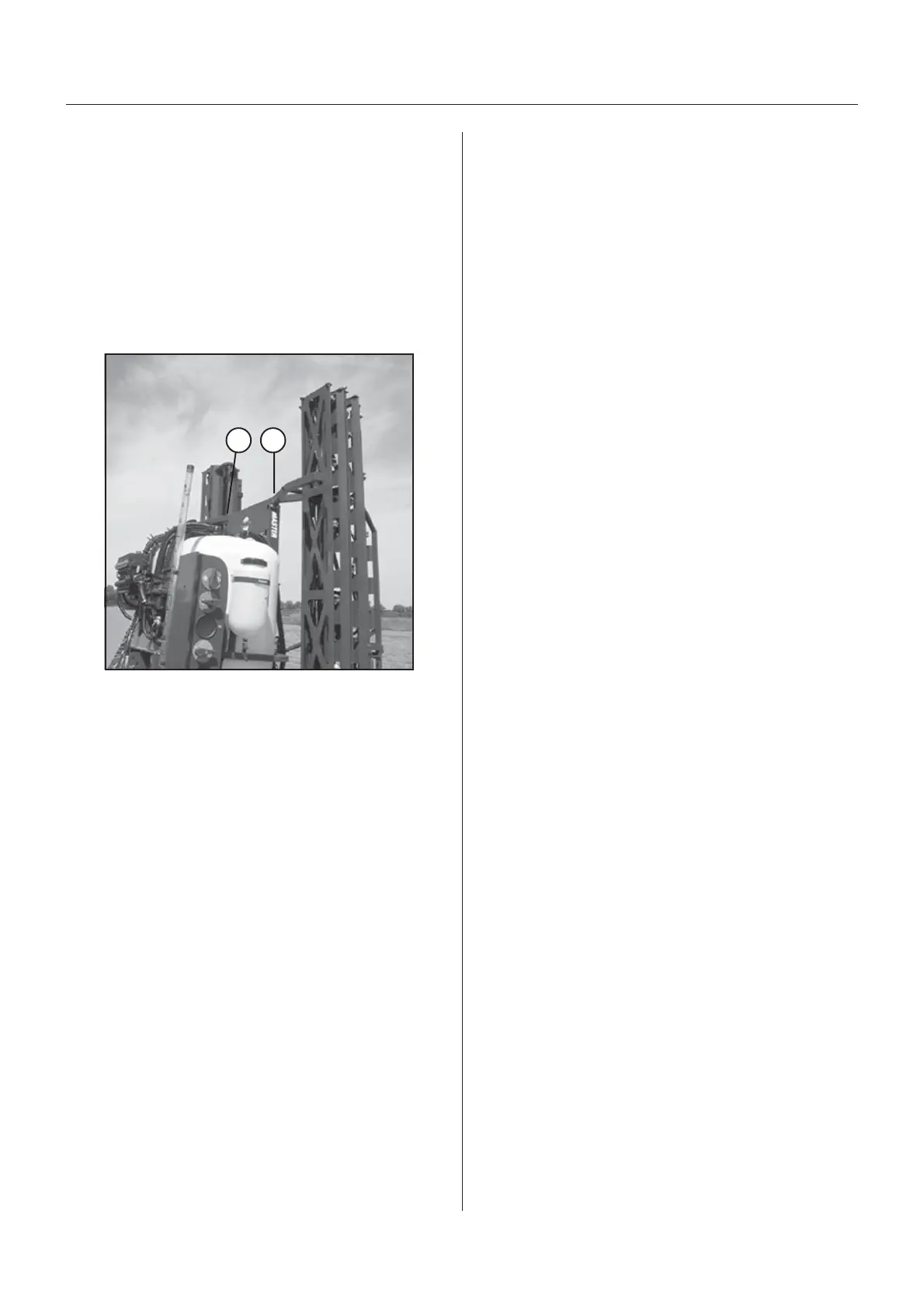

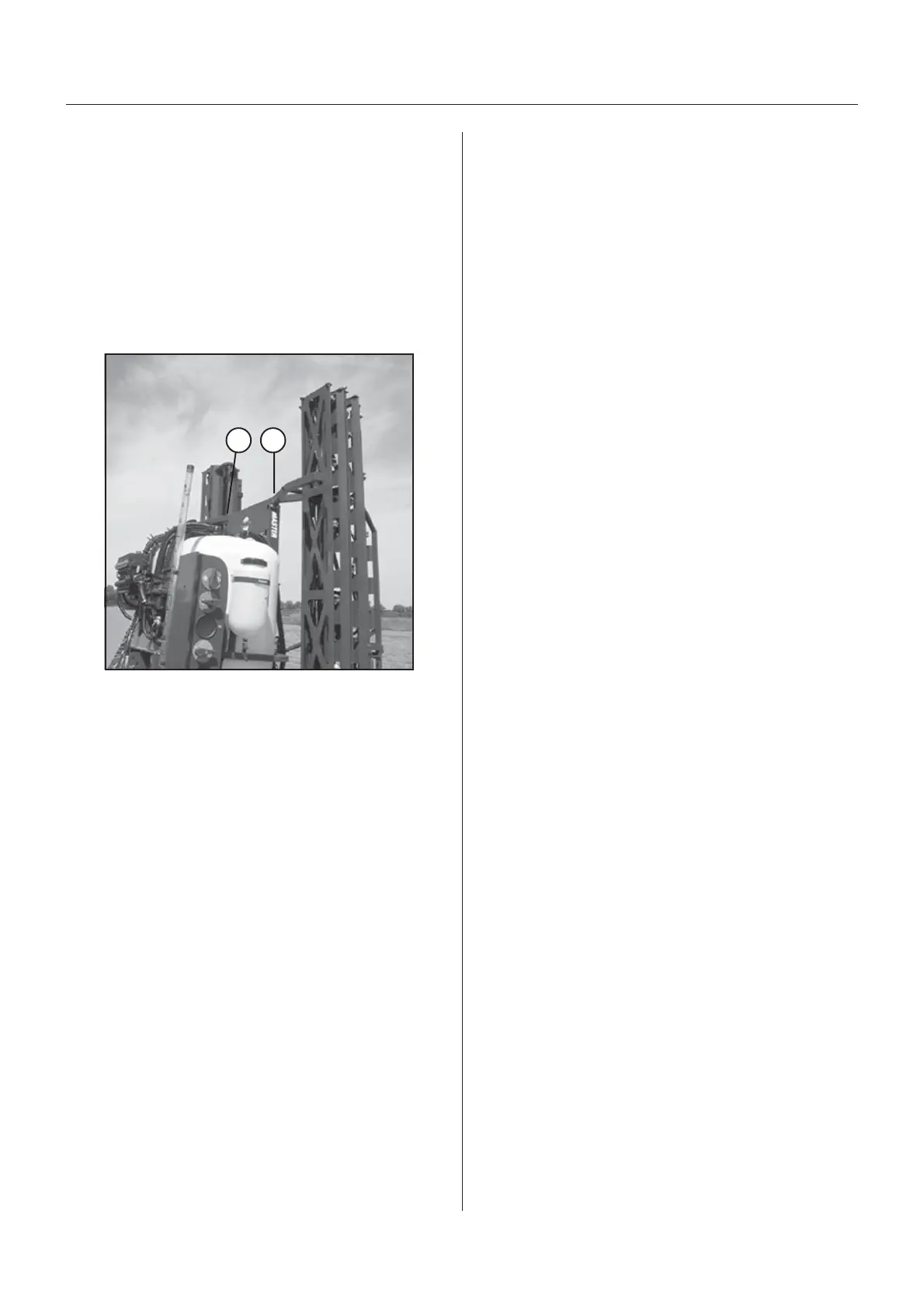

For the unloading of the sprayer, you need a crane or a

fork lift.

When unloading with a crane please observe the two

lifting points (A) as shown on the picture below, and

make sure that the straps or belts used for lifting are

strong enough.

BefBef

BefBef

Bef

oror

oror

or

e putting the spre putting the spr

e putting the spre putting the spr

e putting the spr

aa

aa

a

yy

yy

y

er intoer into

er intoer into

er into

operoper

operoper

oper

aa

aa

a

tiontion

tiontion

tion

Although the sprayer has been applied with a strong and

protective surface treatment on steel parts, bolts etc. in

the factories, it is recommended to apply a film of

anticorrosion oil (e.g. CASTROL RUSTILLO or SHELL

ENSIS FLUID) on all metal parts in order to avoid

chemicals and fertilisers discoloring the enamel.

If this is done before the sprayer is put into operation for

the first time, it will always be easy to clean the sprayer

and keep the enamel shiny for many years.

This treatment should be carried out every time the

protection film is washed off.

T102-0025

A A

Loading...

Loading...