6 - Maintenance

84

Service and Maintenance intervals

General Info

The periodic service and maintenance work in this section may be carried out by the user. Contact your HARDI® dealer if in

doubt. If this work is completed correctly, the sprayer will run efficiently and its lifetime will be prolonged.

Tightening Bolts and Nuts

When tightening bolts and nuts as a part of periodic service or due to replacement of spare parts, it is important to apply

the correct torque. This will prevent accidents and prolong the lifetime of the parts included in the bolted joints.

If not otherwise stated in this book, please tighten bolts and nuts using the following torques.

±

WARNING! Applying too little torque will result in these risks:

±

WARNING! Exceeding the maximum torque will result in these risks:

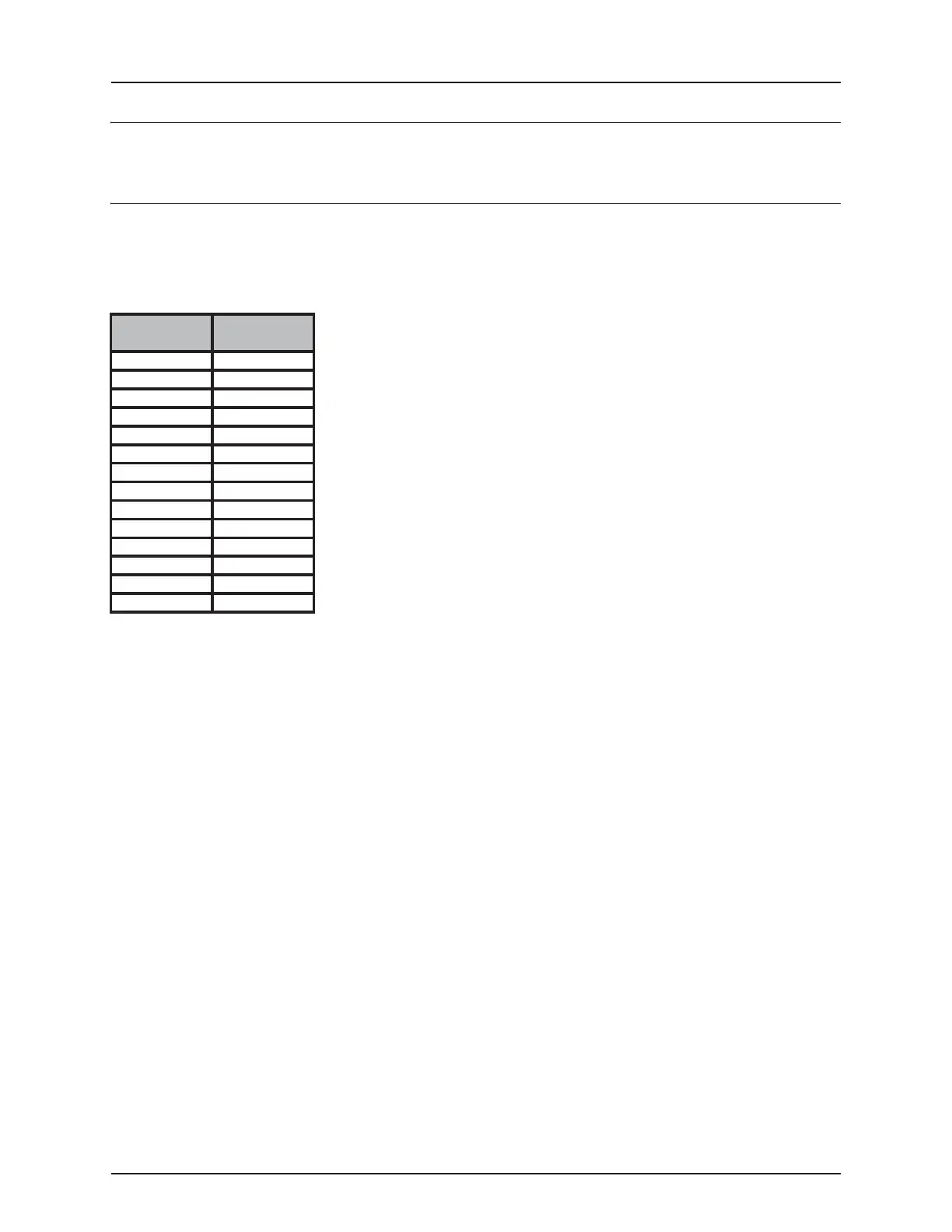

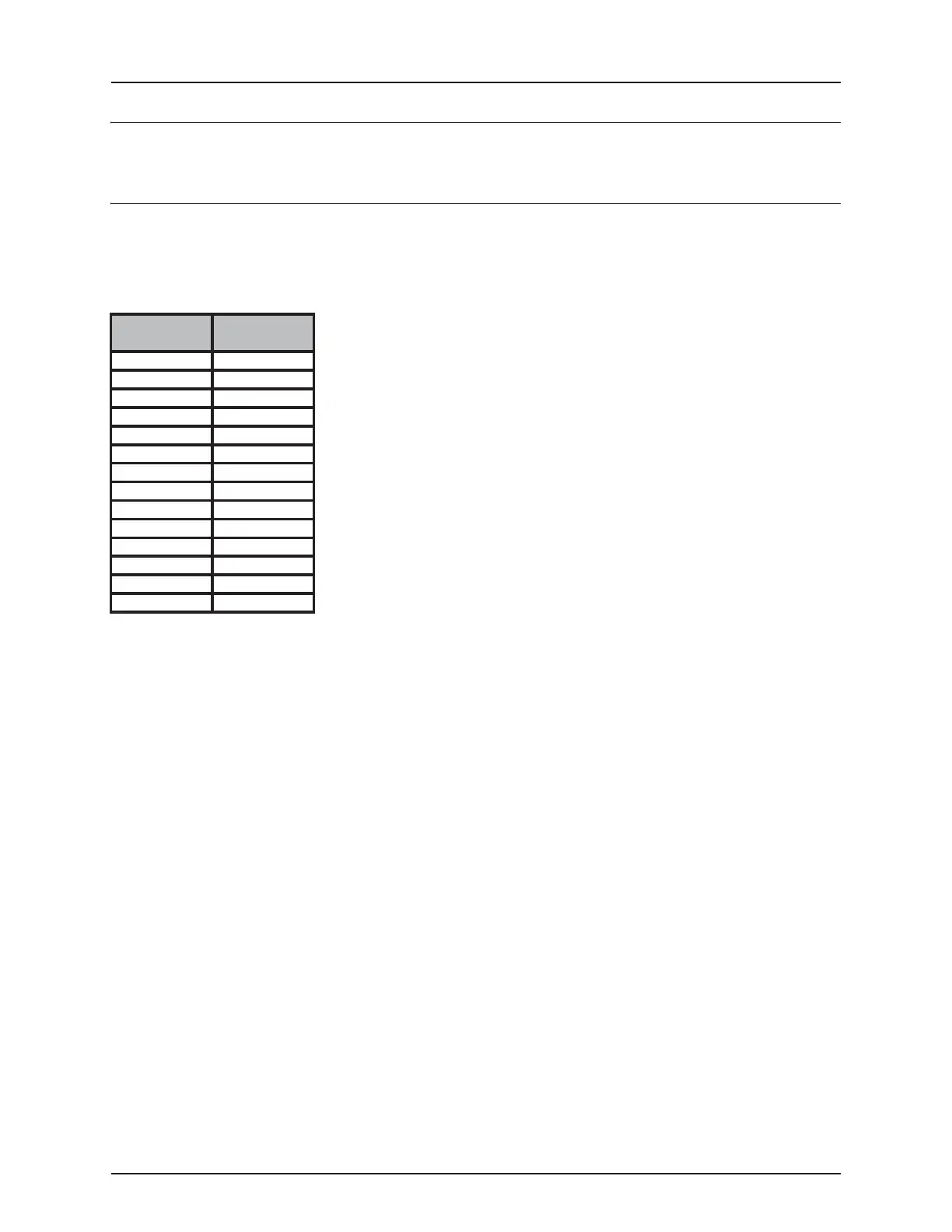

Bolt size

Recommended

torque (Ft/lb)

M4 2

M5 4

M6 6

M8 15

M10 30

M12 50

M14 85

M16 135

M18 175

M20 260

M22 360

M24 445

M27 720

M30 960

• bolted joints will rattle and thus fail under fatigue

• bolts are being worn quickly and thus will not fulfill their design purpose

• bolted joints will come loose

• accidents caused by assembled parts coming apart due to bolts or nuts failing or falling off.

• damaging or stripping the threads and deforming the fastener

• bolt heads will be broken

• bolted joints will come loose

• accidents caused by assembled parts coming apart due to bolts breaking at a later time.

Loading...

Loading...