29

3-90-08101R23_06/13

Burnpot cleaning:

Theburnpotshouldbecleanednolessthanonceaweek.For

bestoperationtheburnpotshouldbecleanedeverytimethe

hopperislledwithpellets.Theredoesnothavetobeout

toscrapetheburnpotalthoughitisrecomendedthefurnace

beonminimumburnatthetimeofcleaning.

Note: The furnacecan easily beturned to minimumburn

regardless of present operation. Simply turn the Mode

SelectortoSERVICE.ThenturntheTempDialtothe#1

setting.Ifthisisdonebeforestartingtorellthehopperthe

furnacewillnotbeashotwhenscrapingtheburnpot.When

the burnpot cleaning is completed don’t forget to turn the

controlbacktotheWallControlpositions.

Usetheatendofthescraperprovidedtoscrapedownover

theholedsurfaceoftheburnpotgrate.SeeFig.62.Itis

notnecessarytocleanoutthescrapingsfromthiscleaning

because they will be pushed out the next time the auger

operates.

Note: Make a special effort to scrape the bottom inside

corners of the burnpot where the auger tube enters the

burnpot.Carbondepositscanbuildupovertimeinthisarea

thatmay causea restriction tothe ow ofpellets into the

burnpot.

Note: Anoldlongshankscrewdriverwiththeendsharpened

isanidealaidintheremovalofthesedeposits.

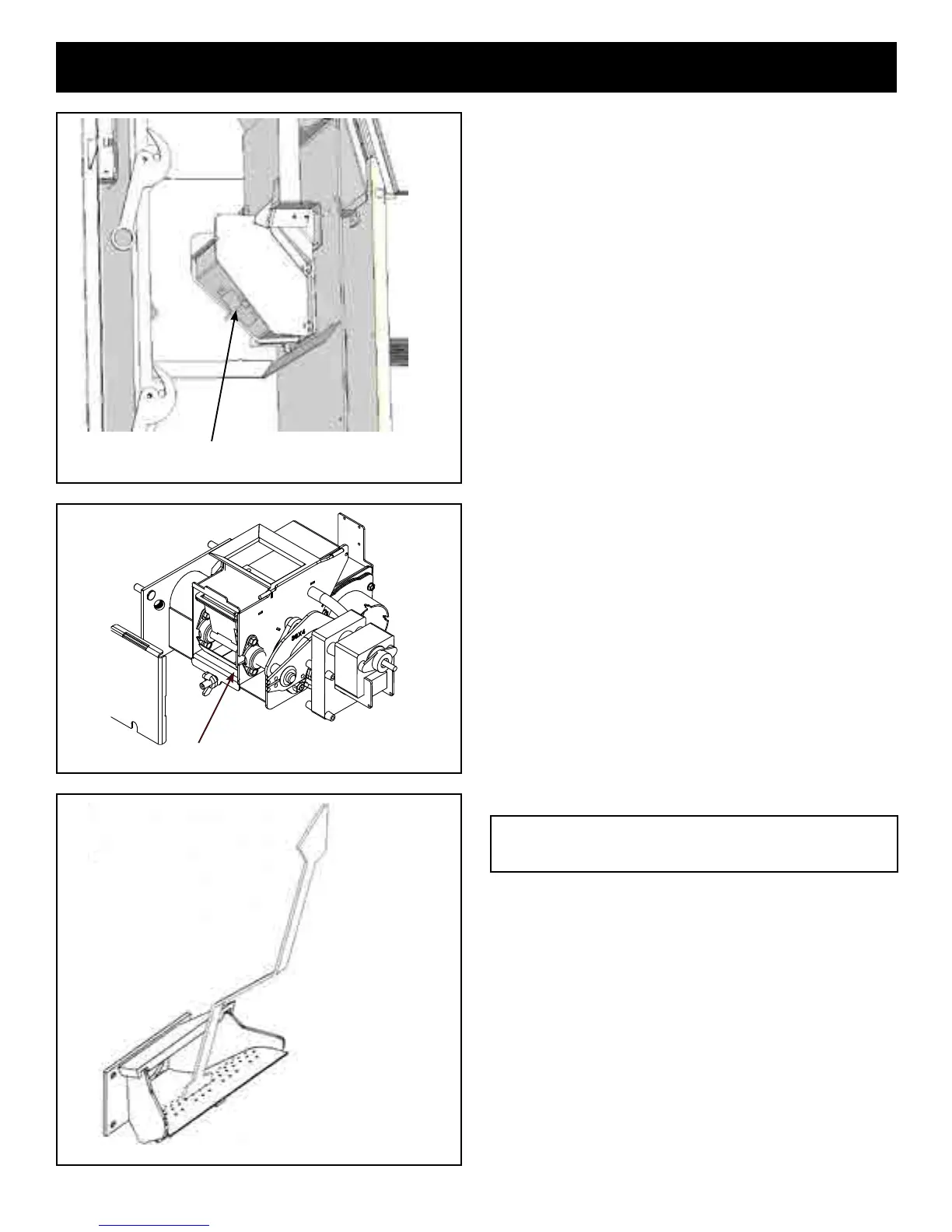

Cleaning the burnpot air chamber:

Thisareaonlyneedstobecleanedtwiceaheatingseason,

unless excessive buildup is noticed during scheduled

cleanings.

Thereisacoveronthefrontoftheburnpottogainaccessto

theairchamber.Thecoverisheldintoplacebytwothumb

screws.Loosen thethumb screws andremove the cover.

SeeFig.60.Theairchambercanbecleanedofanyashthat

hasfallenthroughtheholesduringoperationandcleaning.

NOTE: ALWAYS REMEMBER TO CLOSE THE

CLEANOUT COVER AFTER CLEANING.

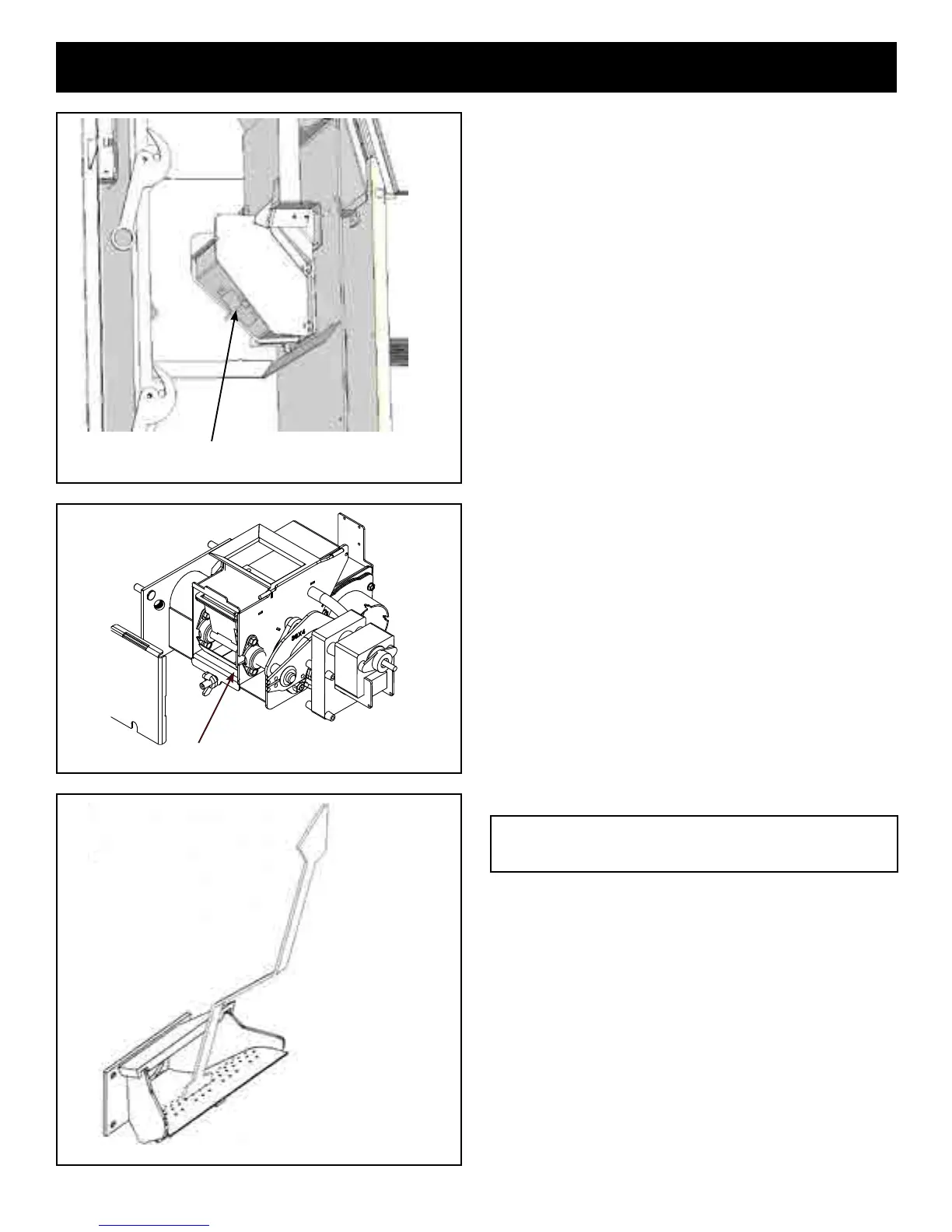

Feeder Chamber (Fig. 61):

This chamber may get a buildup of nes from the feeder

mechanismmovement.This area shouldbe checked and

cleanedatleastonceayear.

To remove the feeder cover:

• Removethewingnut.

• Slidethecoveroffofthethreadedstud.

• Inspectandcleantheinnerchamberifnecessary.See

Fig.61.

• Reinstallthecovermakingcertainitiscenteredonthe

feederbodyandtightenastightlyasyoucanbyhand.

Maintenance

Fig. 60

Fines cleanout cover

Scrape burnpot to remove

any carbon build-up that

may have occured.

Scraping can be done

while in operation.

Fig. 62

Fig. 61

Possiblepelletnesbuilduparea.

Loading...

Loading...