• Calculating average loads: average radial

and axial loads, average output speed

When the radial and/or axial loads vary during motion, calculate and verify

the life of the cross roller bearing converting the loads to their average values.

• Average radial load: Frav

10/3

n

1

t

1

|

Fr

1

|

10/3

+n

2

t

2

|

Fr

2

|

10/3

...n

n

t

n

|

Frn

10/3

Faav= (2)

√

n

1

t

1

+ n

2

t

2

+ ... +nn tn

Note: "Fr

1

" is the maximum radial load in "t

1

" range,

and "Fr

3

" is the maximum radial load in "t

3

" range.

• Average axial load: Faav

10/3

n

1

t

1

|

Fa

1

|

10/3

+n

2

t

2

|

Fa

2

|

10/3

...n

n

t

n

|

Fa

n

|

10/3

Faav= (3)

√

n

1

t

1

+ n

2

t

2

+ ... +n

n

t

n

Note: "Fa

1

" is the maximum radial load in "t

1

" range,

and "Fa

3

" is the maximum radial load in "t

3

" range.

• Average output speed: Nav

10/3

n

1

t

1

+n

2

t

2

+...n

n

t

n

(4)

Nav=

t

1

+ t

2

+ ... + t

n

• Calculating radial load factor and axial load factor

Both load factors are different with average loads as follows:

•

When the right formula is satisfied,

Faav

Frav + 2(Frav ( L r+ R ) + Faav

.

La ) /dp

<1.5 (5)

X=1.0, and Y=0.45

•

When the formula below is satisfied,

Faav

Frav + 2(Frav ( Lr + R ) + Faav

.

La ) /dp

>1.5 (5’)

X=0.67, and Y=0.67

Where, the variables of the formula are:

Mmax: Maximum torsional moment in N•m(kgf•m); obtained by the formula (1)

Frmax: Maximum radial load in N(kgf); See Fig.1.

Famax: Maximum axial load in N(kgf); See Fig.1.

Lr, La: Loading point in mm; See Fig.1.

R: Offset; See Fig.1 and Table 1.

dp: Circular pitch of roller: See Fig.1 and Table 1.

Chapter 2 Guidelines for sizing

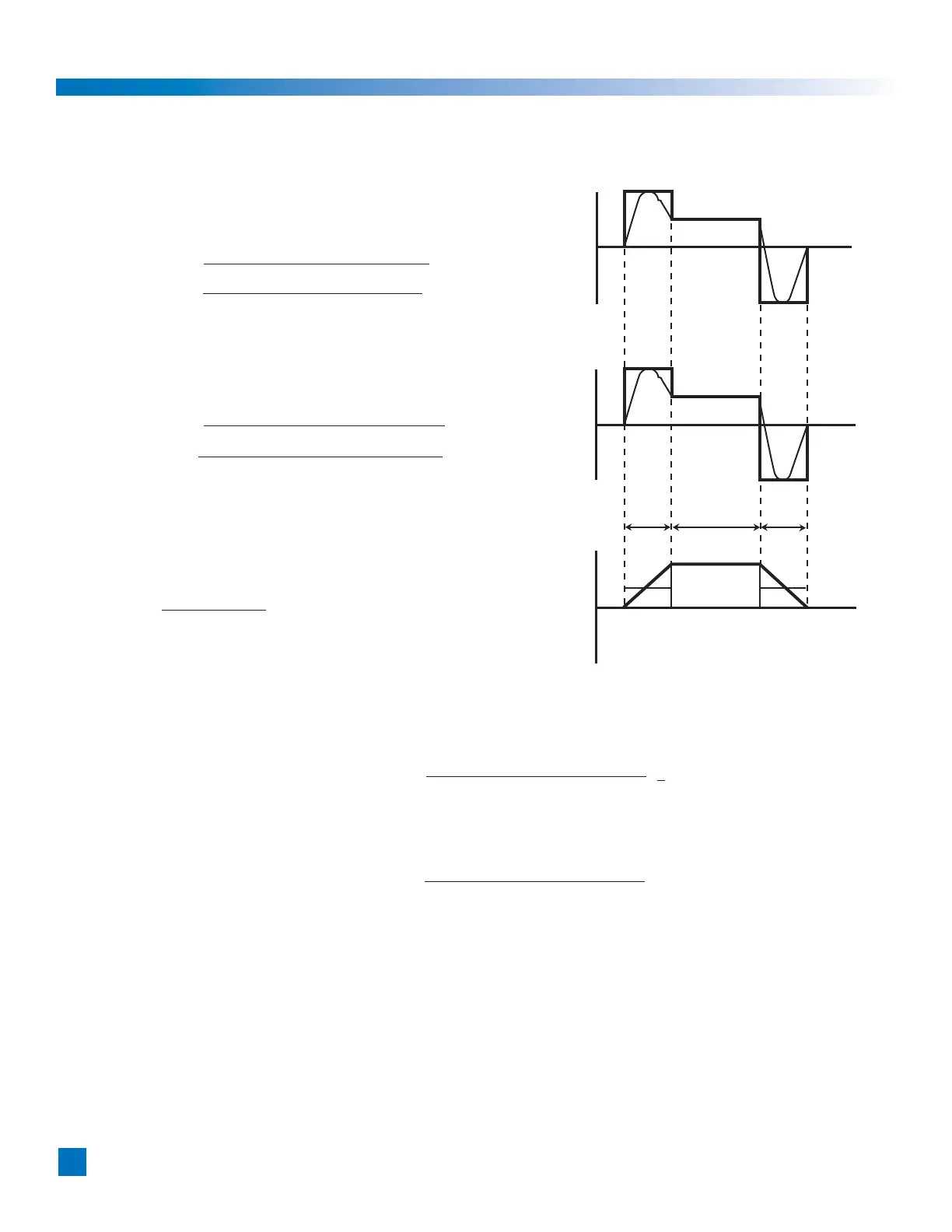

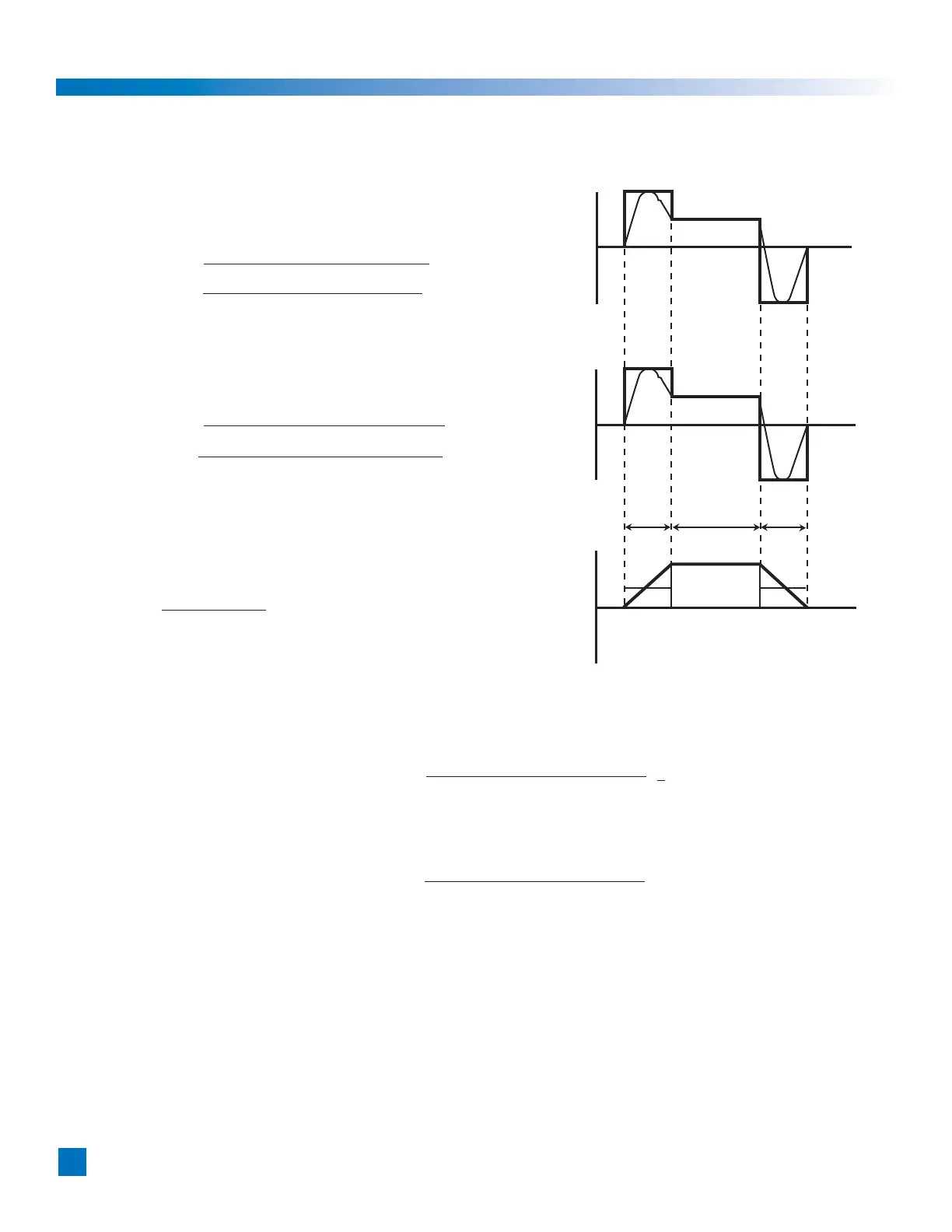

Time

Time

Time

Fr

1

Fr

2

Fa

1

Fa

2

Fr

3

Fa

3

t

1

t

2

t

3

n

1

n

2

n

3

– Axial load +

– Axial load +– Axial load +

21

Loading...

Loading...