Harmonic Drive LLC 800-921-3332

26

Chapter 2 Guidelines for sizing

Speed

N

Time

ta

tr td ts

t: duty cycle

Time

Ta

Tr

Ta

Tor qu e

KLr

2-4-5 Calculating equivalent duty

The load conditions, which is torque, speed, moment of inertia,

acceleration/deceleration time, loading time, are limited by the

actuator to drive the load. To select the proper actuator, the

equivalent duty of the load should be calculated.

The %ED (percent equivalent duty) is:

%ED =

K

La x ta + KLr x tr + KLd x td

x 100

t

where, ta: acceleration time in second

td: deceleration time in second

tr: driving time in second

t: single cycle time in second

K

La: duty factor for acceleration time

K

Lr: duty factor for driving time

K

Ld: duty factor for deceleration time

•

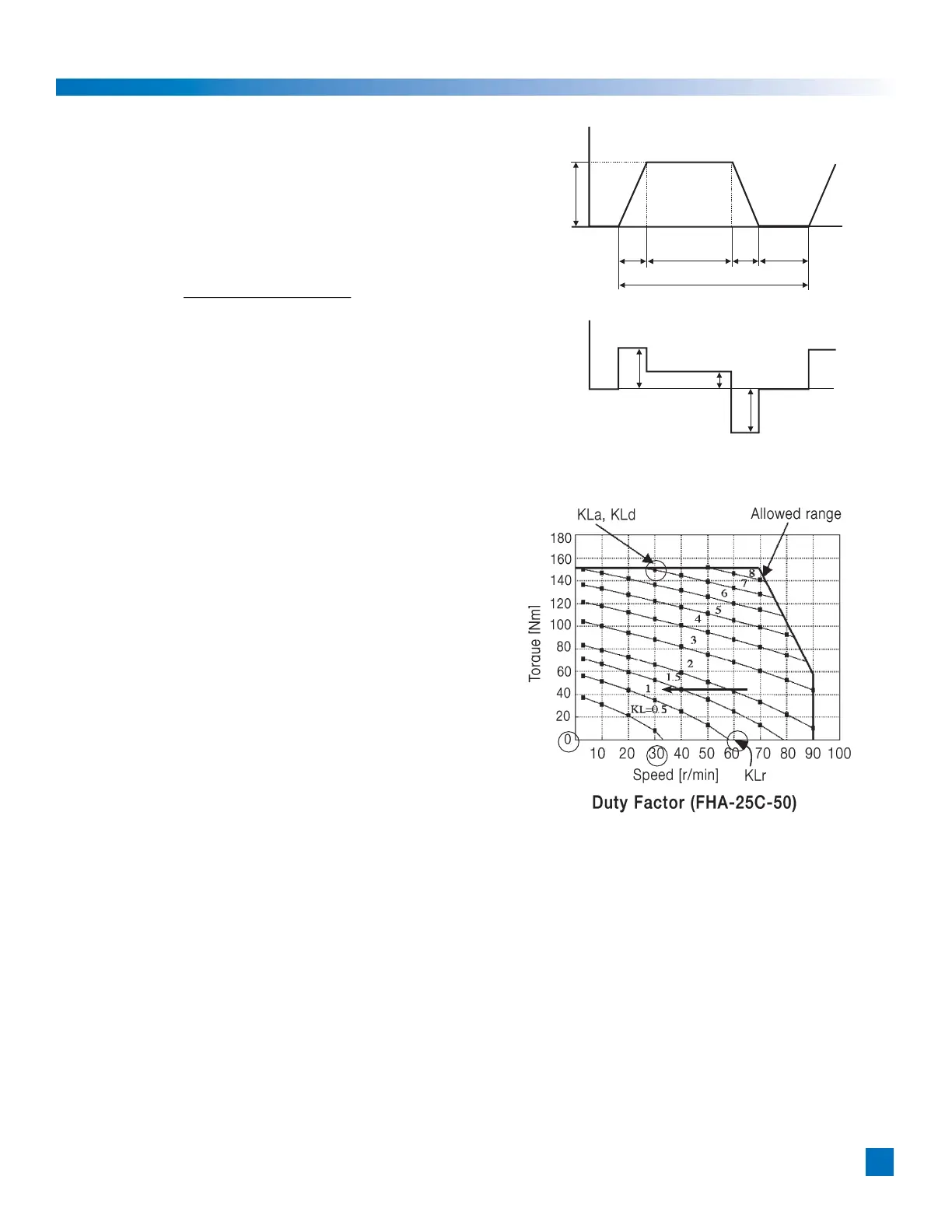

Example 2: getting duty factors of KLa, KLr and KLd

With an example of the duty factor graph for FHA-25C-50 actuator,

the way of getting the duty factors of K

La, KLr and KLd is described

as follows:

The load conditions are the same as the example described in

example 1: the inertia load is accelerated by the maximum

torque,

and is driven with a constant speed, and decelerated by the

maximum torque. The displacement angle is 120 degrees and

the cycle time is 2.0 s.

(1) K

La, and KLd: the speed is desired at 30 r/min as

the average of 0 and 60 r/min.

Then, K

La = KLd = 7.0 from the graph.

(2) K

Lr (ex.: KLr =1.0) from the graph pointing the load torque

Tr (ex. Tr= 0) and driving speed (ex: Nr=60r/min).

(3) The driving time is calculated as the area of the

trapezoid of speed-time graph. Then the

displacement angle is:

θ

= (N / 60) x {tr + (ta + td) / 2} x 360

Then, tr =

θ

/ (6 x N) – (ta +td) /2

As the 120 deg. is equal to 0.33rev (=120/360), the driving angle at the speed of 60r/min (=1r/s) is:

tr = (0.333-0.091)/1 = 0.242 s

(4) Because the cycle time is 2.0s, the %ED is obtained as follows:

%ED = (7 x 0.097+1 x 0.242 + 7 x 0.085) / 2 x 100 = 76%

It is possible to drive the actuator with the load specifications continuously,

because the %ED is less than 100%.

If the %ED is excesses 100%, correct the situation by:

• Changing the speed-time profile

• Reducing load moment of inertia

• Selecting an actuator with a larger frame size

Loading...

Loading...