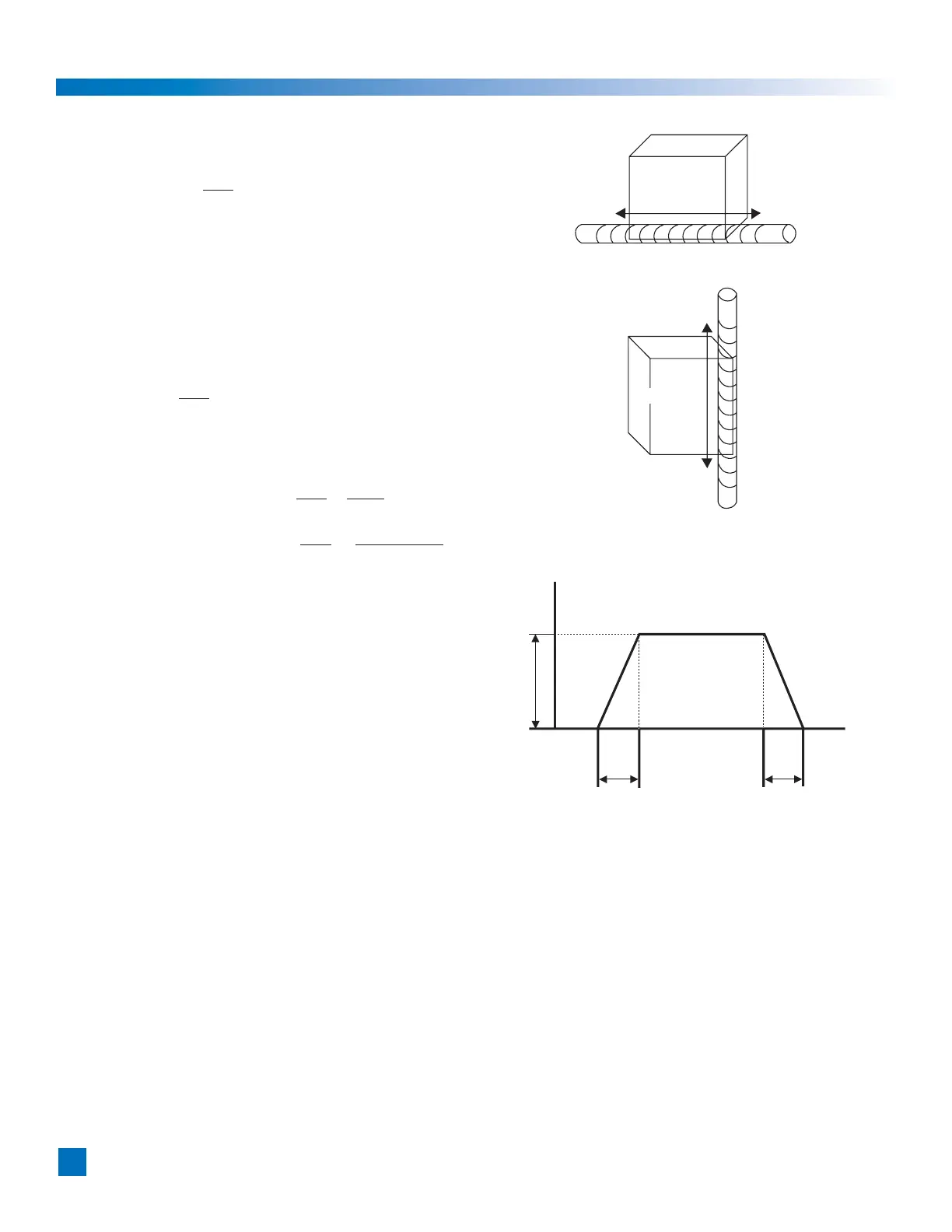

• Horizontal linear motion

The following formula calculates the torque for horizontal

linear motion of mass [W] fed by the screw of pitch [P].

T = 9.8 x μ x W x

P

2 x π

T : torque (N

•m)

μ

: coefficient of friction

W : mass (kg)

P : screw pitch (m)

• Vertical linear motion

The following formula calculates the torque for vertical

linear motion of mass [W] fed by the screw of pitch [P].

T = 9.8 x W x

P

2 x π

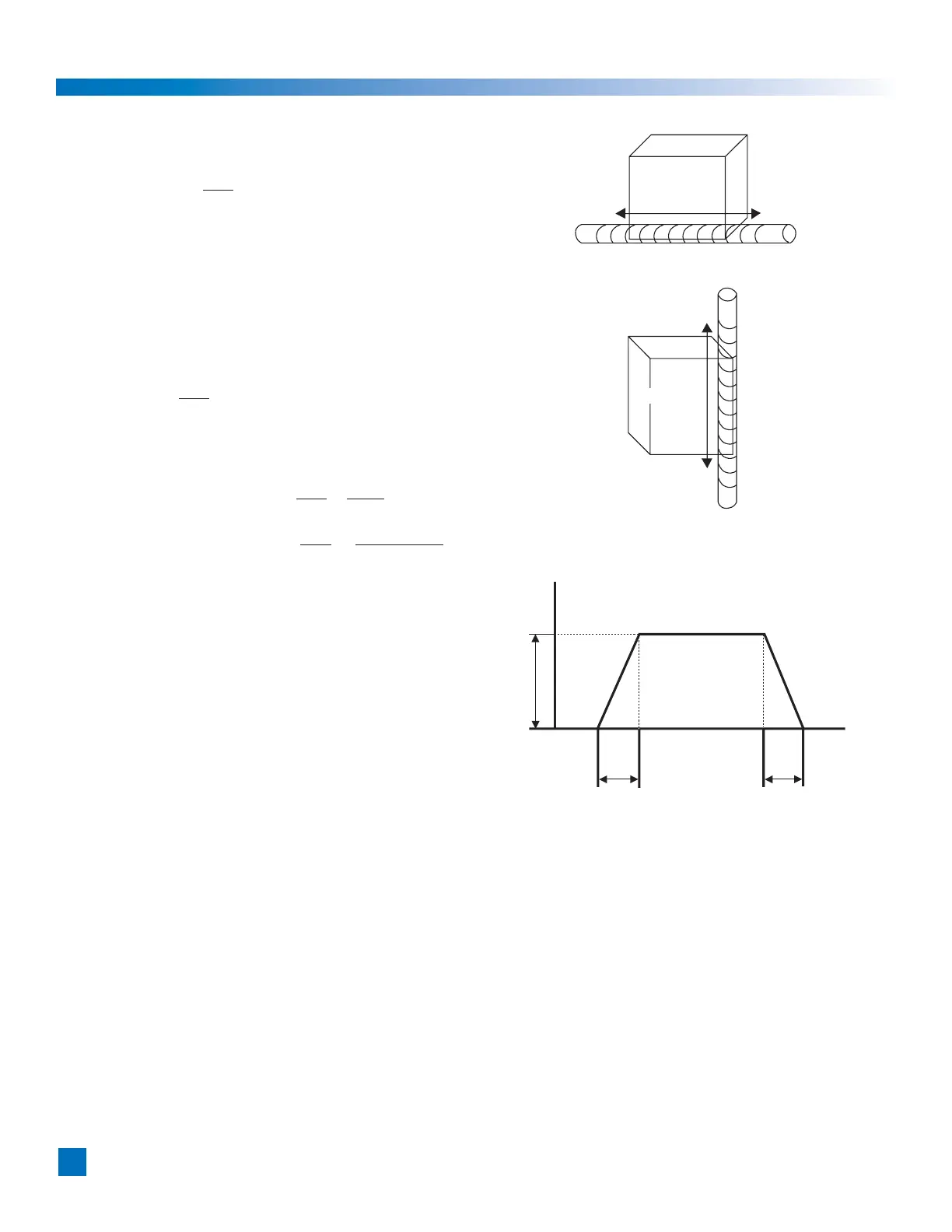

2-4-4 Acceleration time and deceleration time

Calculate acceleration and deceleration times for the selected actuator.

Acceleration: ta = (J

A + JL) x

2 x π

x

N

60 T

M – TL

Deceleration: td = (JA + JL) x

2 x π

x

N

60 T

M + 2 x TF – TL

Ta: acceleration time (sec)

T

d: deceleration time (sec)

J

A: actuator inertia (kg•m

2

)

J

L: load inertia (kg•m

2

)

N: actuator speed (r/min)

T

M: maximum torque of actuator (N•m)

T

F: actuator friction torque at max. speed (N•m)

T

F = KT x IM - TM

where, KT: torque constant (N•m/A)

I

M: maximum current (A)

T

L: load torque (N•m)

note that the polarity of the load torque is

plus (+) for counter direction of revolution,

and minus (-) for same direction.

•

Example 1

The load conditions are: Rotary speed: 60r/min

Moment of inertia: 1.5 kg

•m

2

Load torque is so small as to be neglected.

(1) Referring the figure in section 2-1, FHA-25C-50 actuator is selected for the load.

(2) Referring the specification table provided in section 1-4, J

A=0.81 kg•m

2

, TM =150 N•m, KT=22 N•m/A,

and I

M =7.3A are obtained for the FHA-25C-50.

(3) T

F = 22 x 7.3 – 150 = 10.6 N•m is obtained with the formula above.

(4) Acceleration and deceleration times are: ta = (0.81+1.5 ) x 2 x

π

/ 60 x 60 / 150 = 0.097 s

td = (0.81+1.5) x 2 x

π

/ 60 x 60 / (150 + 2 x 10.6) = 0.085 s

(5) If the calculated acceleration times are too long, correct the situation by:

• Reducing load moment of inertia

• Selecting an actuator with a larger frame size

25

Chapter 2 Guidelines for sizing

Mass: W

Mass: W

Pitch: P

Pitch: P

Friction:

Speed

N

Time

ta

td

Loading...

Loading...