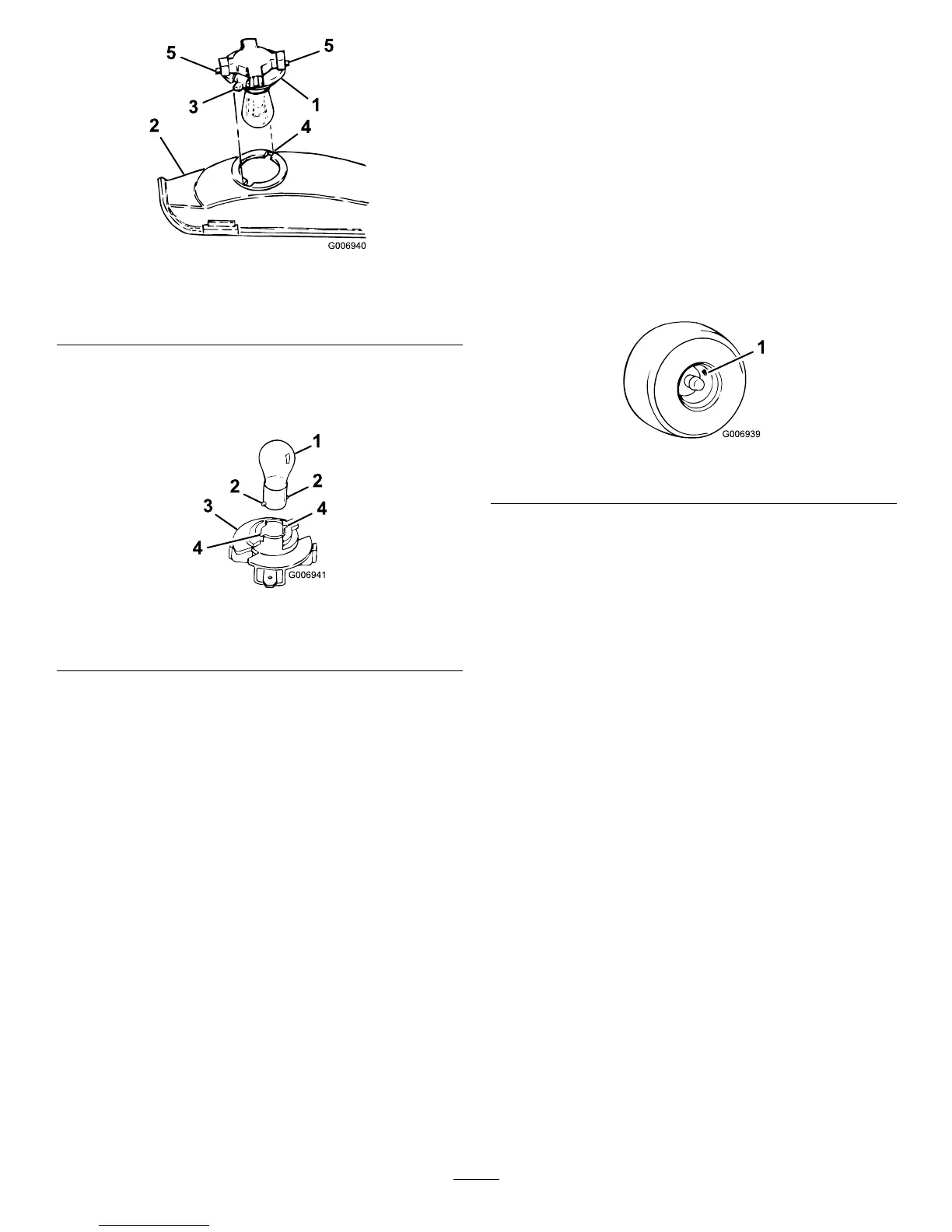

Figure39

1.Bulbholder

4.Slots

2.Reector

5.Terminals

3.Tabs

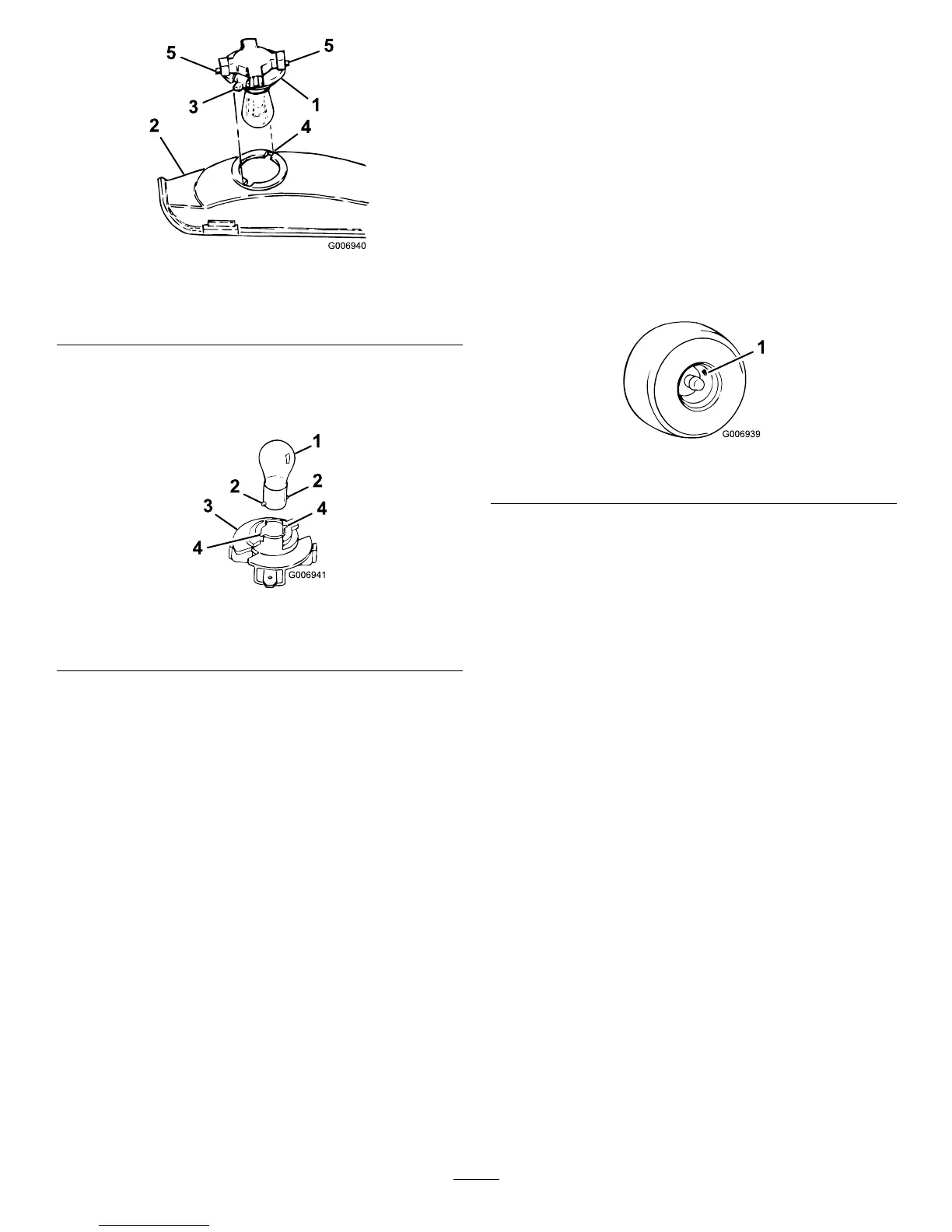

4.Insertandrotatethebulbcounterclockwiseuntilit

stops(approx.1/4turn),andremovethebulbfrom

thebulbholder(Figure40).

Figure40

1.Bulb3.Bulbholder

2.Metalpins

4.Slots

InstallingtheBulb

1.Alignthemetalpinsonthesideofthebulbbase

withtheslotsinthebulbholder.

2.Insertthebaseintotheholder(Figure40).

3.Pushandrotatethebulbclockwiseuntilitstops.

4.Alignthetabsonthebulbholder(Figure39)with

theslotsinthereector,insertthebulbholderinto

thereector,androtateit1/4turnclockwiseuntil

itstops.

5.Connectthewireconnectorstotheterminalsonthe

bulbholder.

DriveSystem

Maintenance

CheckingtheTyrePressure

ServiceInterval:Every25hours

Maintaintheairpressureinthefrontandreartyresat

20psi(138kPa).Checkthepressureatthevalvestem

(Figure41)afterevery25operatinghoursoryearly,

whicheveroccursrst.Checkthetyreswhentheyare

coldtogetthemostaccuratepressurereading.

Figure41

1.Valvestem

ServicingtheTransaxleFluid

ServiceInterval:Every100hours—Servicethe

transaxleuid.

Alwayskeeptheuidlevelatthefulllevelwhenthe

transaxleiscold.

Note:Thetransaxleisfactorysealedanddoesnot

requireoilchanges.

FluidType:SAE20W-50engineoil(APIservice

SH/CDisrecommended)

CheckingtheFluidLevel

1.Parkthetractoronalevelsurface.

2.Disengagethebladecontrol(PTO)andsetthe

parkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanaroundthellplug(Figure42)sothatdirt

cannotfallintothereservoirifyouneedtoadduid.

32

Loading...

Loading...