Preventive Maintenance 20 17730-241

AR2

™

■

1. Chock the wheels.

2. Visually inspect suspension components for signs of movement or excessive wear.

■

Inspect equalizing beam end connection for signs of excessive wear or looseness

■

Look for worn, frayed or distorted rubber in the beam, see Figure 6-4

■

Look for the equalizing beam to be lower in the axle bracket, see Figure 6-4

■

If it is visually offset a jack test should be performed. Place a jack under each beam end

as shown. Raise the jack to check for movement in the connection or rubber components,

see Figure 6-5

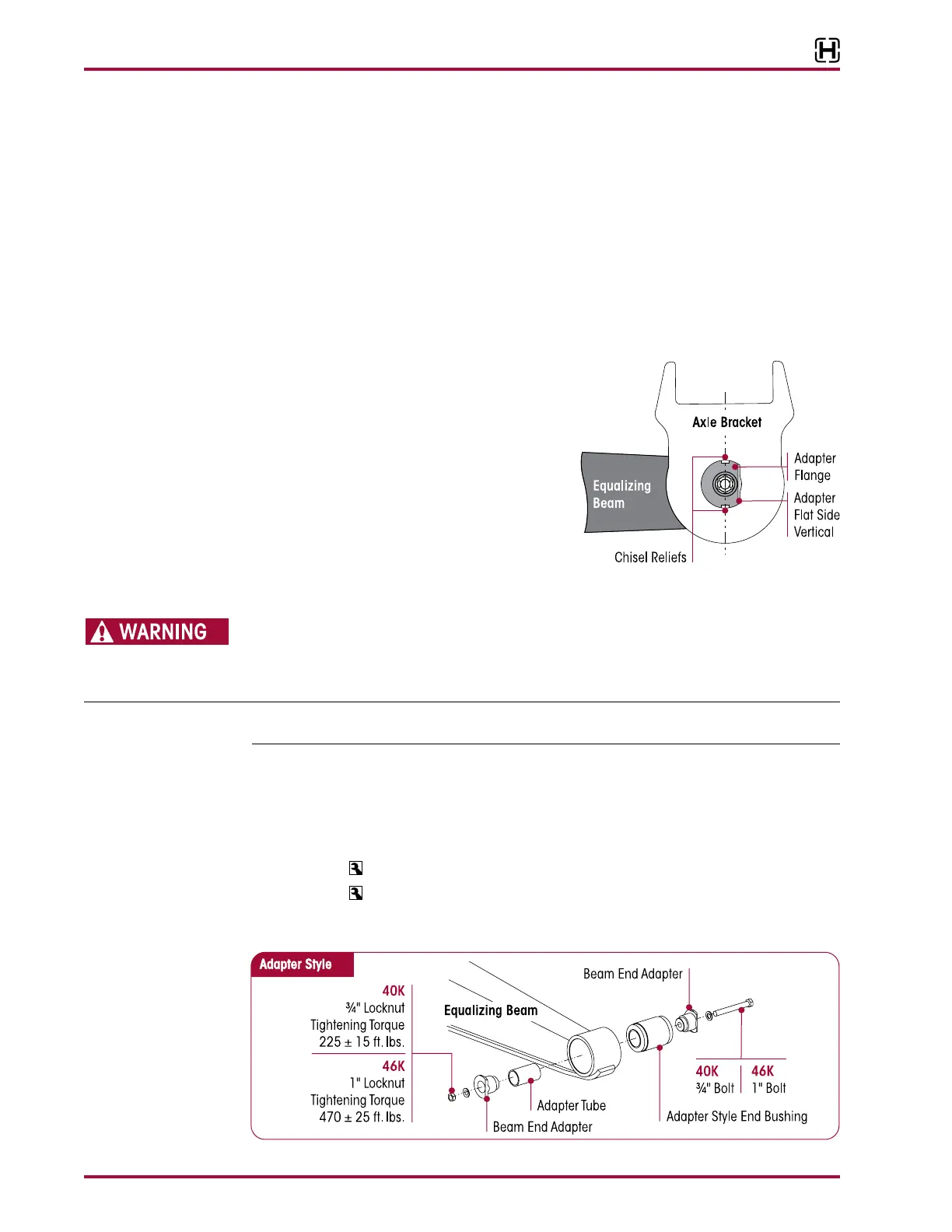

3. The beam end adapter style connections have

an adapter flange with a flat side for assembly

clearance with the axle housing bowl.

■

The flat must be positioned vertically as

shown in Figure 6-7. If the flat of the adapter

position is incorrect, removal of the fasten-

ers will be necessary to correct position,

refer to the Adapter Style End bushings in the

Component Replacement section

■

IF BUSHING MOVEMENT OR LOOSENESS IS NOTED IN THE EQUALIZING BEAM END HUB, DO NOT

OPERATE THE VEHICLE. REPLACE THE RUBBER END BUSHINGS AND ALL CONNECTING PARTS.

THE ABOVE CONDITION CAN RESULT IN COSTLY REPAIR, DOWNTIME, POSSIBLE SEPARATION OF

COMPONENTS, ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE, OR PERSONAL INJURY.

An equalizing beam end connection that is visibly cleaner than the other connections may indi-

cate a loose connection.

1. If bushing movement or looseness is detected in the equalizing beam end hub, oper-

ate vehicle. Replace the equalizing beam end bushings and all connecting parts. Refer to the

Component Replacement section of this publication.

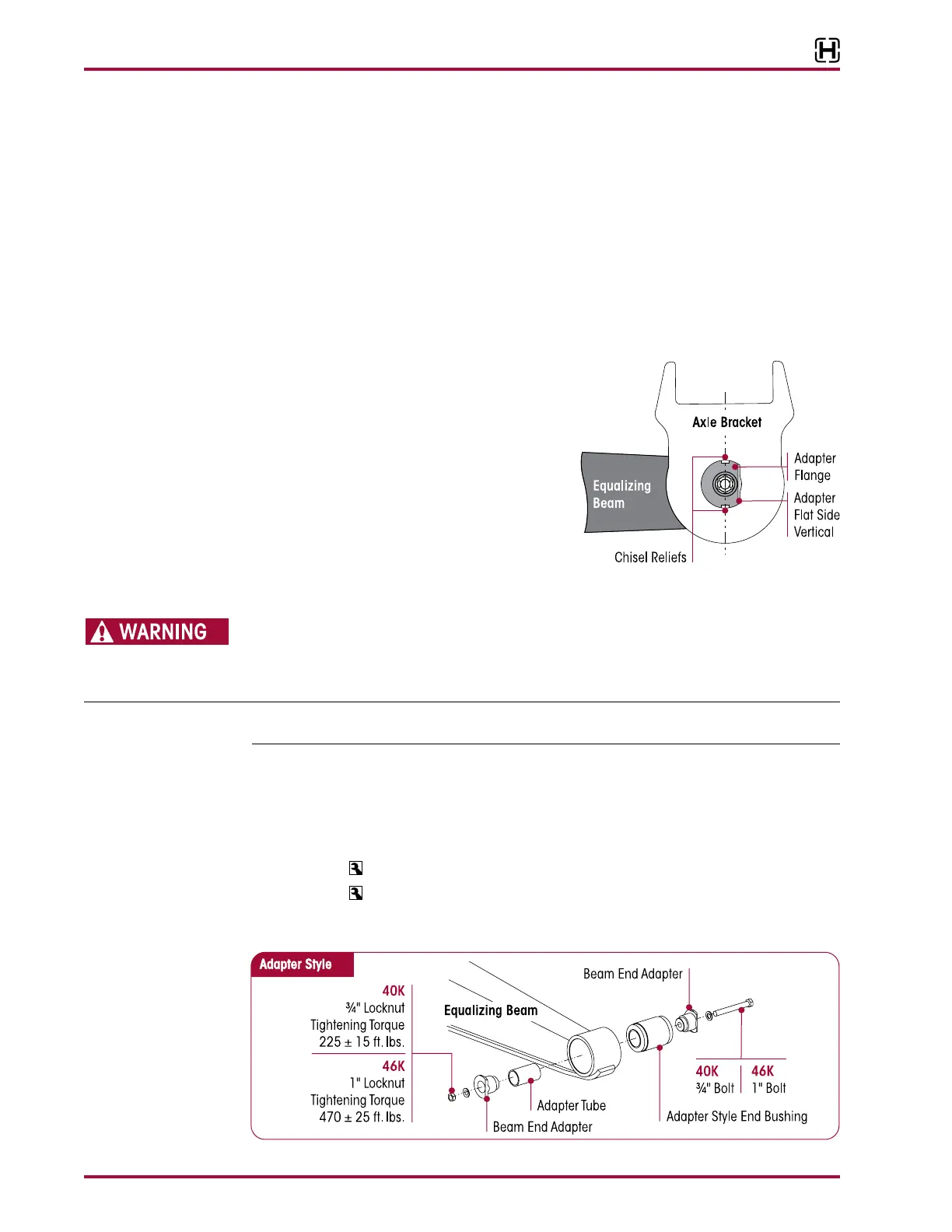

2. Check and record torque values, see Figure 6-8. Ensure all fasteners are tightened to the

following:

■

40K — 225 ± 15 foot pounds torque

■

46K — 470 ± 25 foot pounds torque

3. Recheck equalizing beam end connections for signs of looseness.

Loading...

Loading...