for the technician

System filling

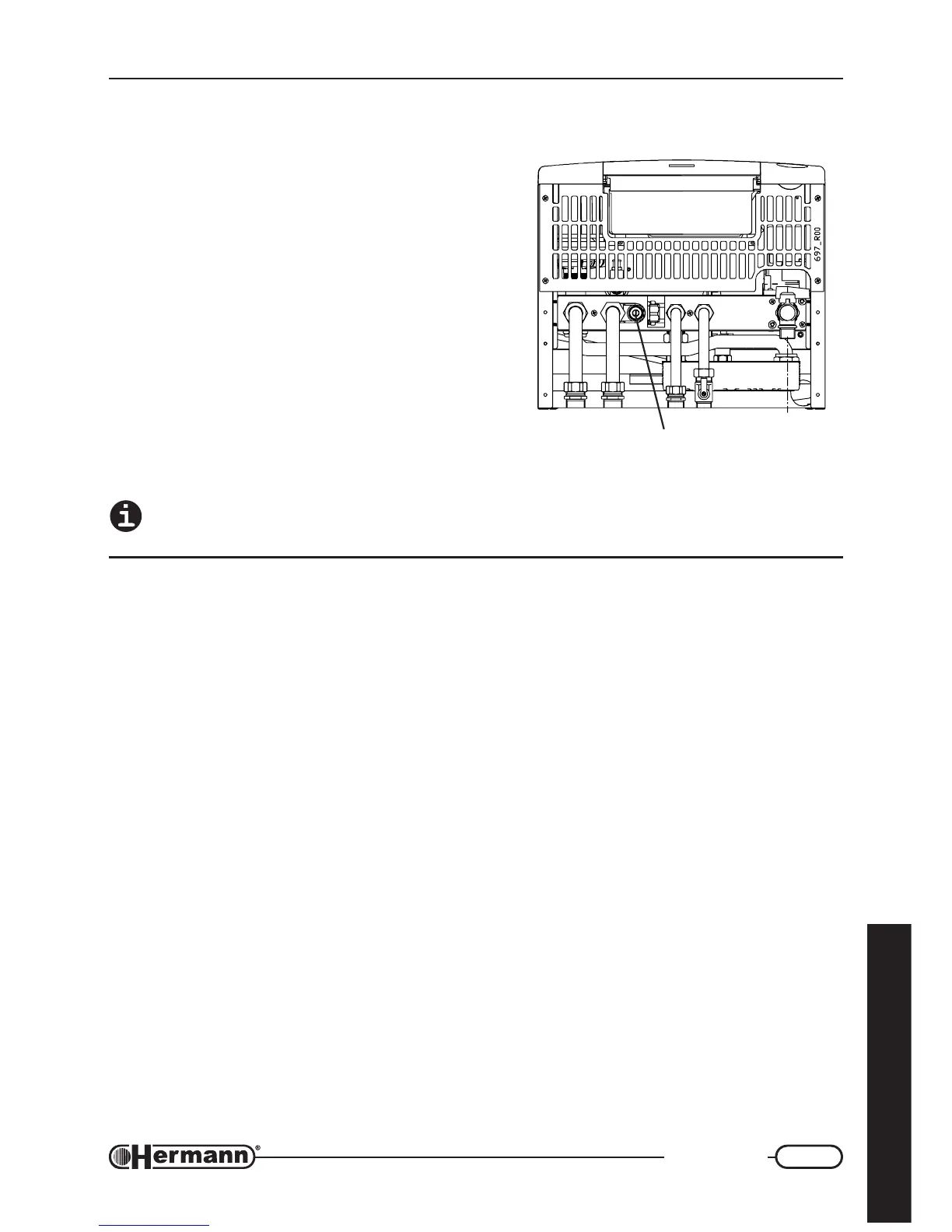

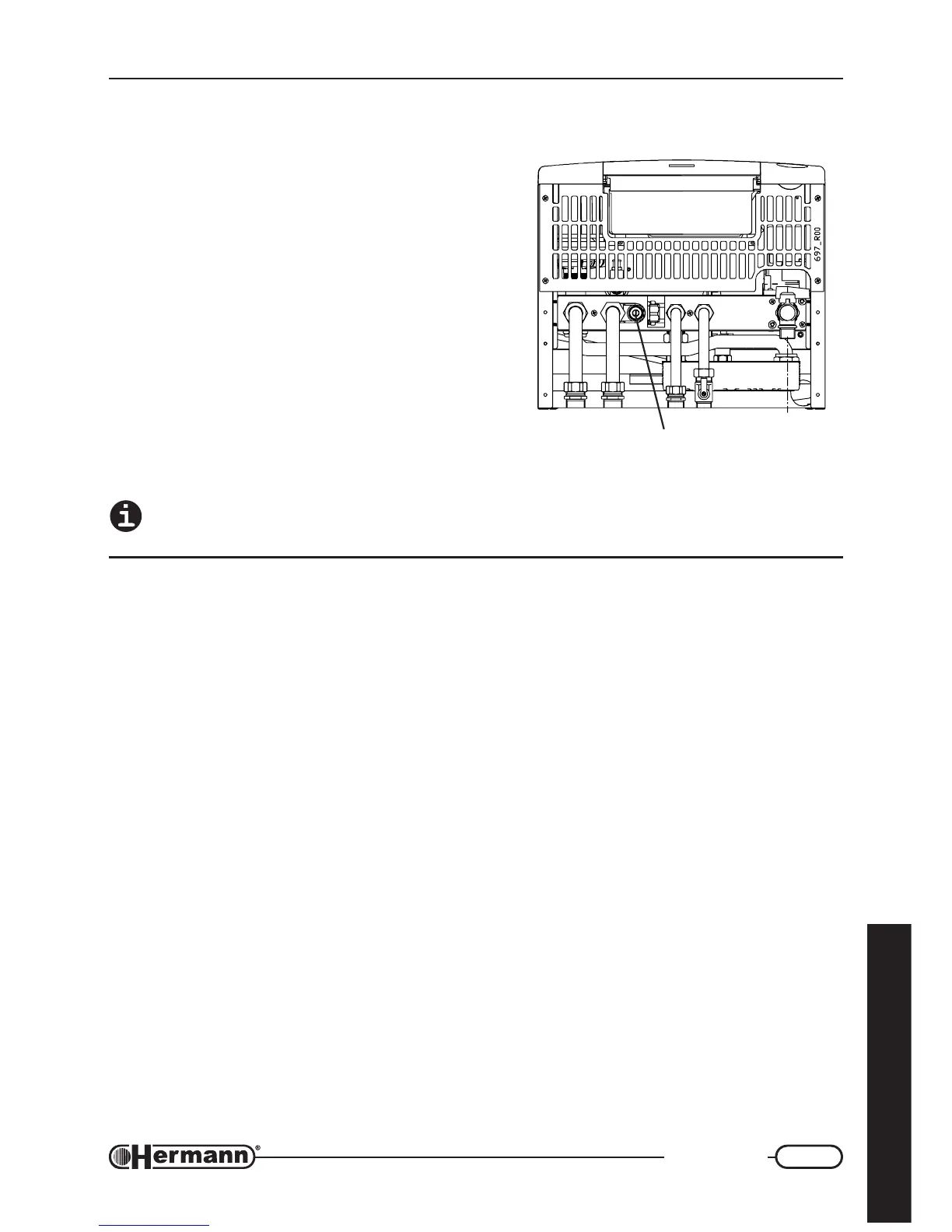

Once all system connections have been carried out,

proceed with system filling. This operation should be

made with caution, respecting the following steps:

— Open the radiators venting devices;

— Gradually open the water supply valve (see figure

“Boiler bottom view”), checking the correct func-

tioning of automatic venting devices, eventually

installed;

— Close the radiators venting devices as soon as

water flows;

— Make sure that pressure gauge reaches the opti-

mal value of 1÷1.5 bar (minimum: 0.5 bar);

— Close the water supply valve and bleed each ra-

diator;

In case the boiler is installed in rooms where temperature can drop down to 0°C, it is advis-

able to fill up the system with an anti-frost liquid.

Gas connection

Boiler installation must be carried out from a qualified technician, [as indicated by the Law XXXXX]

because an incorrect installation can cause damages to people, animals or things, for which the

manufacturer cannot be held responsible.

Verify what follows:

a) cleaning of all system gas pipes in order to avoid the presence of residual combustion products

that could compromise the correct boiler functioning;

b) gas line and ramp conformity with laws and rules actually in force (Laws UNI-CIG 7129/01 and

7131/99 – DM 12/04/96);

c) internal and external tightness of the gas system and connections;

d) supply pipe must have a section greater than or equal to the boiler one;

e) supply gas must correspond to the one for which the boiler has been regulated; otherwise, call

[an HERMANN Servicing Centre] [a qualified technician] for gas conversion;

f) an interception valve must be installed upstream the appliance;

Open the meter valve and purge the air that is inside the system pipes (including all the appli-

ances).

BOILER BOTTOM VIEW

FILLING

VALVE

Loading...

Loading...