for the technician

1

3

700_R01

5

6

6

4

2

REGULATION AND SERVICING

ATTENTION: the operations described below must be carried out only by qualified

personnel [authorized by HERMANN].

When regulation/measuring is over, remember to tighten pressure tapping point screws

and ALWAYS check for gas leaks!

Before boiler ignition, verify that pump is not blocked due to its inactivity: unscrew the plug

located in the middle of the cap to gain access to the rotor shaft, and turn it manually using

a screwdriver or another suitable tool.

During the first ignition of the brand new boiler, it is necessary that burner works for at least

30 minutes, before performing combustion checks. During this time, the fumes of the eventual

residual manufacturing materials are produced, and they could alter the measured values.

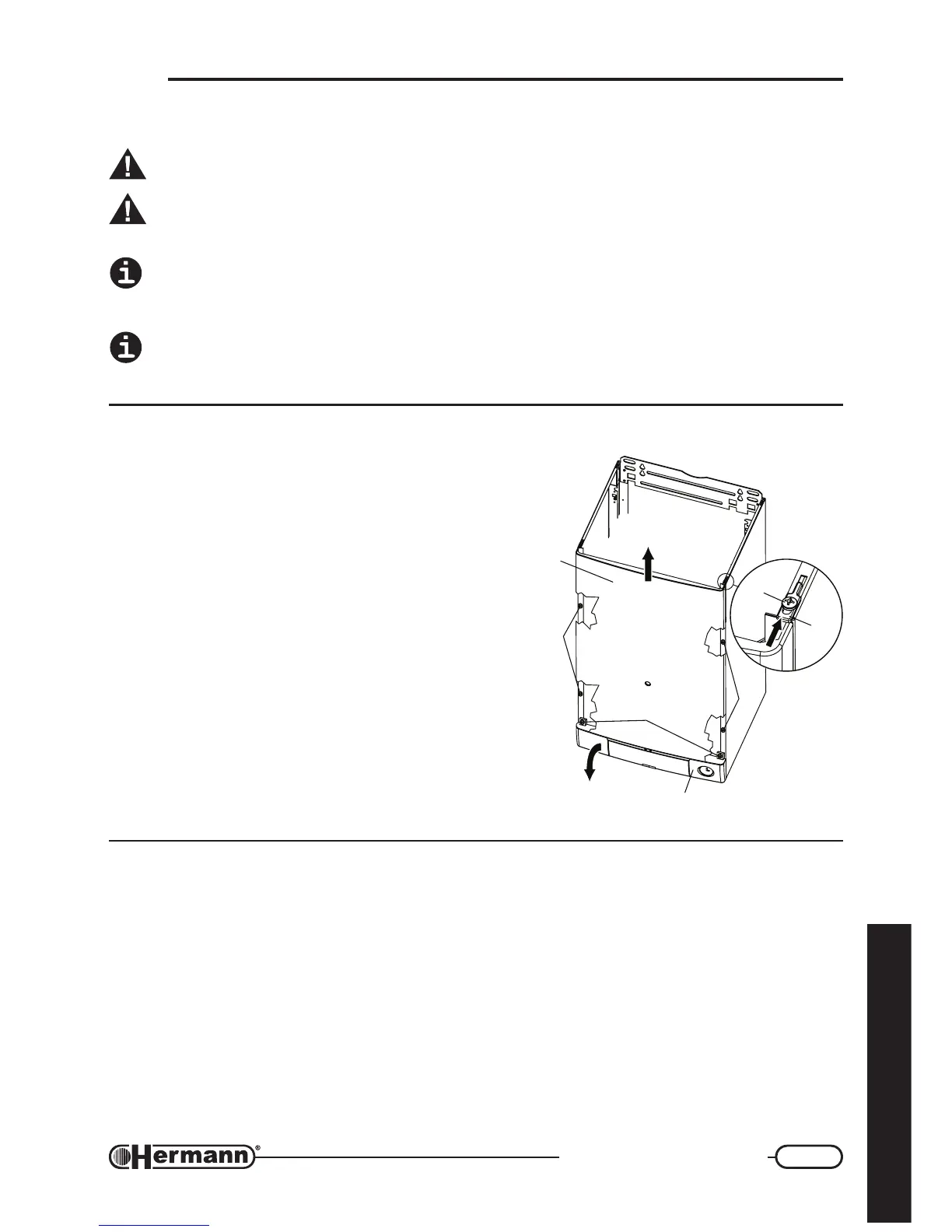

Access to the regulation devices

1. Unscrew the screws [1] and let the catches slide [2]

in order to release the front casing [3];

2. Push the front casing [3] upwards and remove it;

3. Unscrew the two screws [4] and overturn downwards

the control panel [5];

4. After the regulations, close the boiler repeating eve-

rything in the other sense, paying attention to hook

the frontal casing to the heads of the four screws [6]

(which must not be released) and remembering to

stop it through the catches [2] and through the

screws [1].

Preliminary GAS checkings

All boilers are tested and factory set during manufacture; however, it is advisable to check that the

gas type and the burner pressures are correct. On the contrary, follow the procedures described in

this section.

To make burner pressures checking, insert pressure gauge sensors in the gas valve pressure

tapping points (see figure).

Remark: In order to check that pressure and gas input are enough to guarantee the correct func-

tioning of the appliance , make measurements while burner is on.

Loading...

Loading...