for the technician

Changing Gas type

ATTENTION: the operations described below must be carried out only by qualified

personnel [authorized from HERMANN Ltd].

For gas conversion, use the nozzles supplied by boiler manufacturer only.

Using LPG, it is absolutely necessary to install a pressure reducer upstream the boiler.

1. Disconnect the boiler from the electrical supply.

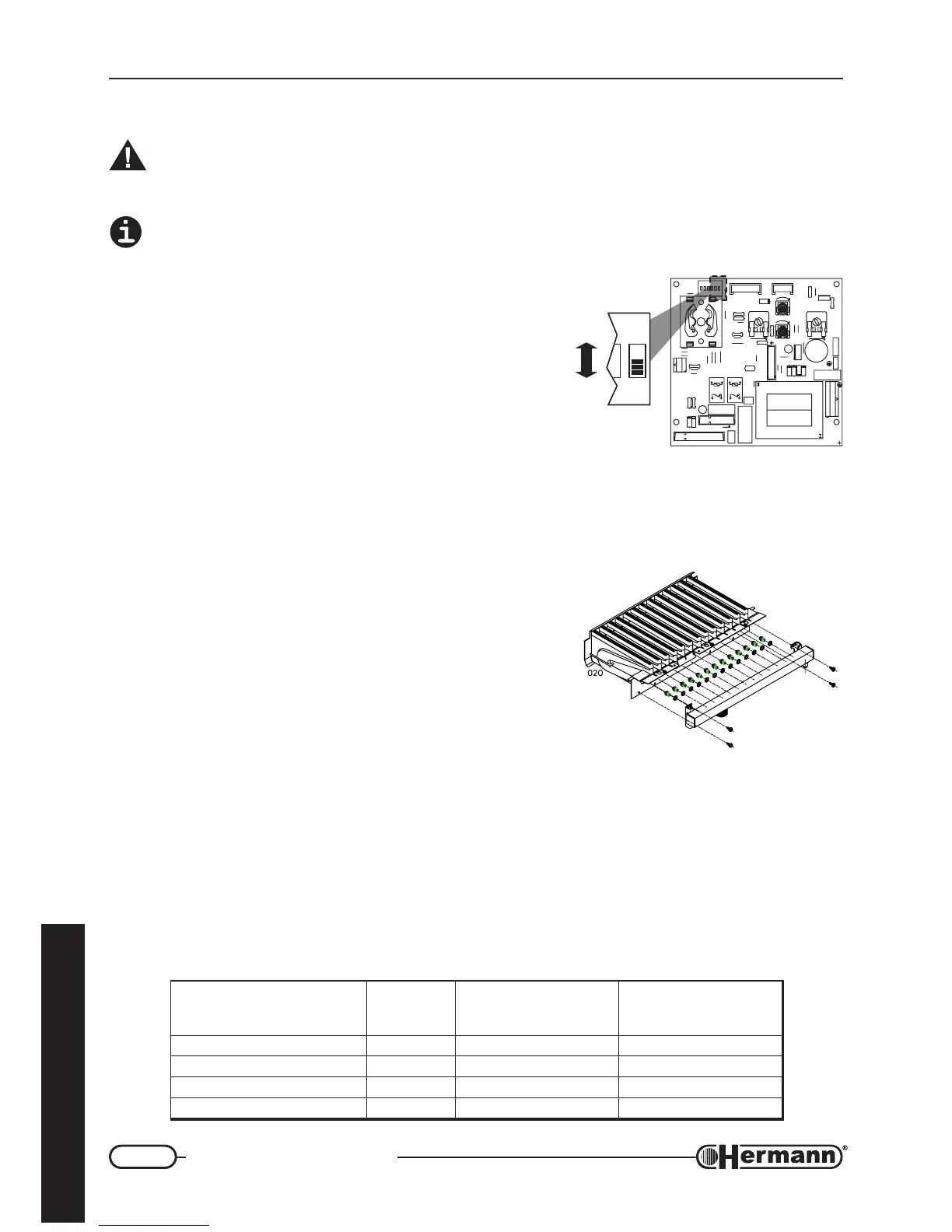

2. Remove the cover of the control panel and move the

first microswitch of SW3 (on the right) in the position

suitable for the gas available:

MET (OFF) for Natural Gas (G20),

GPL (ON) for Butane (G30) or Propane (G31)

3. Check that pressure and gas input are enough to

guarantee the correct functioning of the appliance.

4. On “SE” models, open sealed combustion chamber.

5. Remove pipe between gas valve and injectors bar.

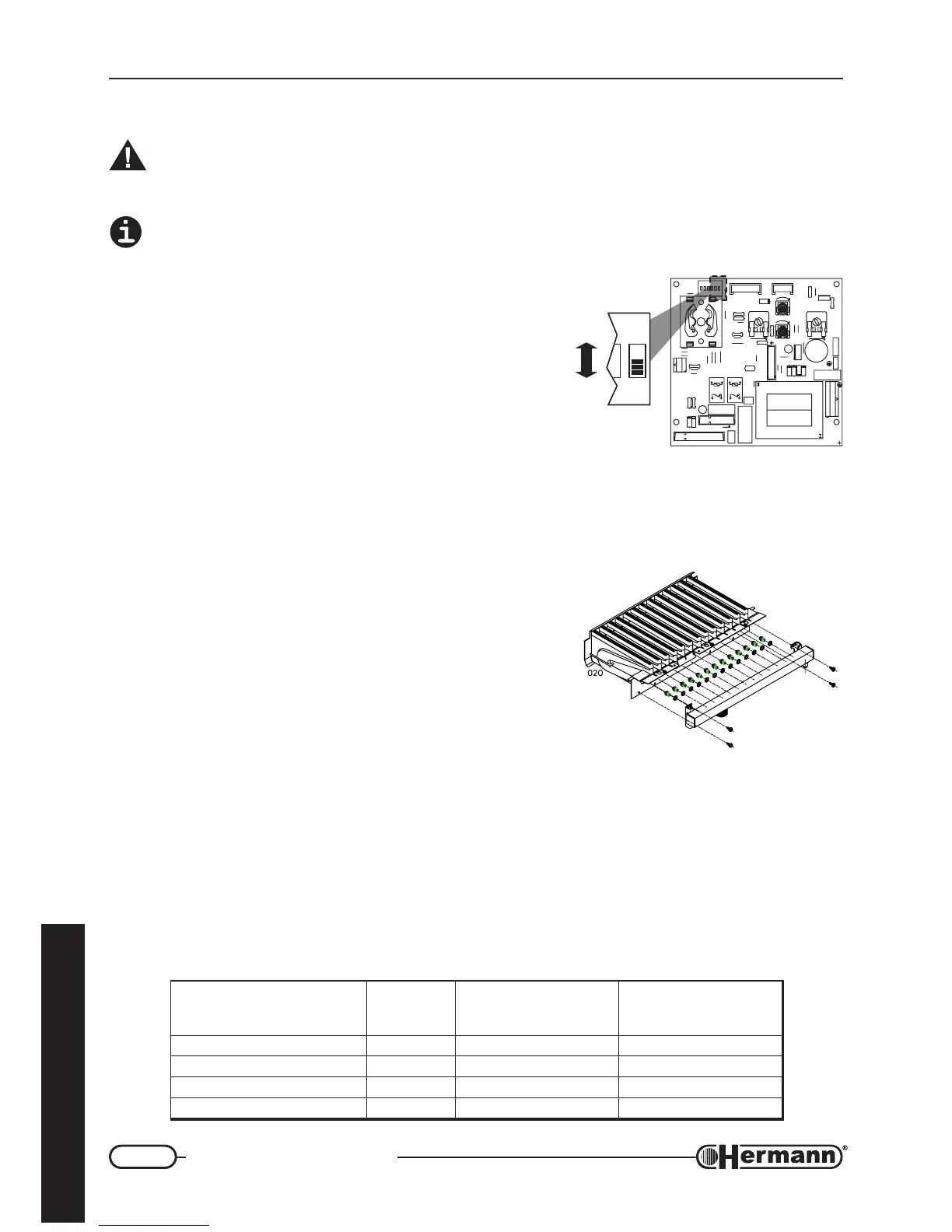

6. Remove injectors bar and replace the nozzles with the

ones suitable for the available gas type, using a 7 mm.

spanner (see figure “BURNER”). Reassemble injectors

bar and pipe, replacing gaskets. Check, with burner ON,

that there are no gas leaks. On “SE” models, close sealed

combustion chamber;

7. Check, with burner ON, that there are no gas leaks and

that the pressure upstream the boiler is:

Natural gas: min.17 – max. 25 mbar

Buthane: min. 25 – max 35 mbar

Propane: min. 25 – max 37 mbar

8. Repeat the following regulations: gas valve MAX-MIN pressure regulation, Slow Opening and

Max Heating Output, carefully following the instructions described in the previous pages.

9. Check that there are no gas leaks.

10. apply the sticker indicating the type of gas (supplied with the kit) on the suitable area on “WARN-

ING” label inside the boiler.

BURNER

LEDOM

rebmuN

selzzonfo

rofØselzzoN

02GSAGLARUTAN

)mm001/1(

rofØselzzoN

13G/03G.G.P.L

)mm001/1(

E32ARCIMREPUS3102157

E82ARCIMREPUS4152167

ES42ARCIMREPUS3102157

ES03ARCIMREPUS4103187

1

SW3

ON

MET

GPL

853R00

51

Loading...

Loading...