7

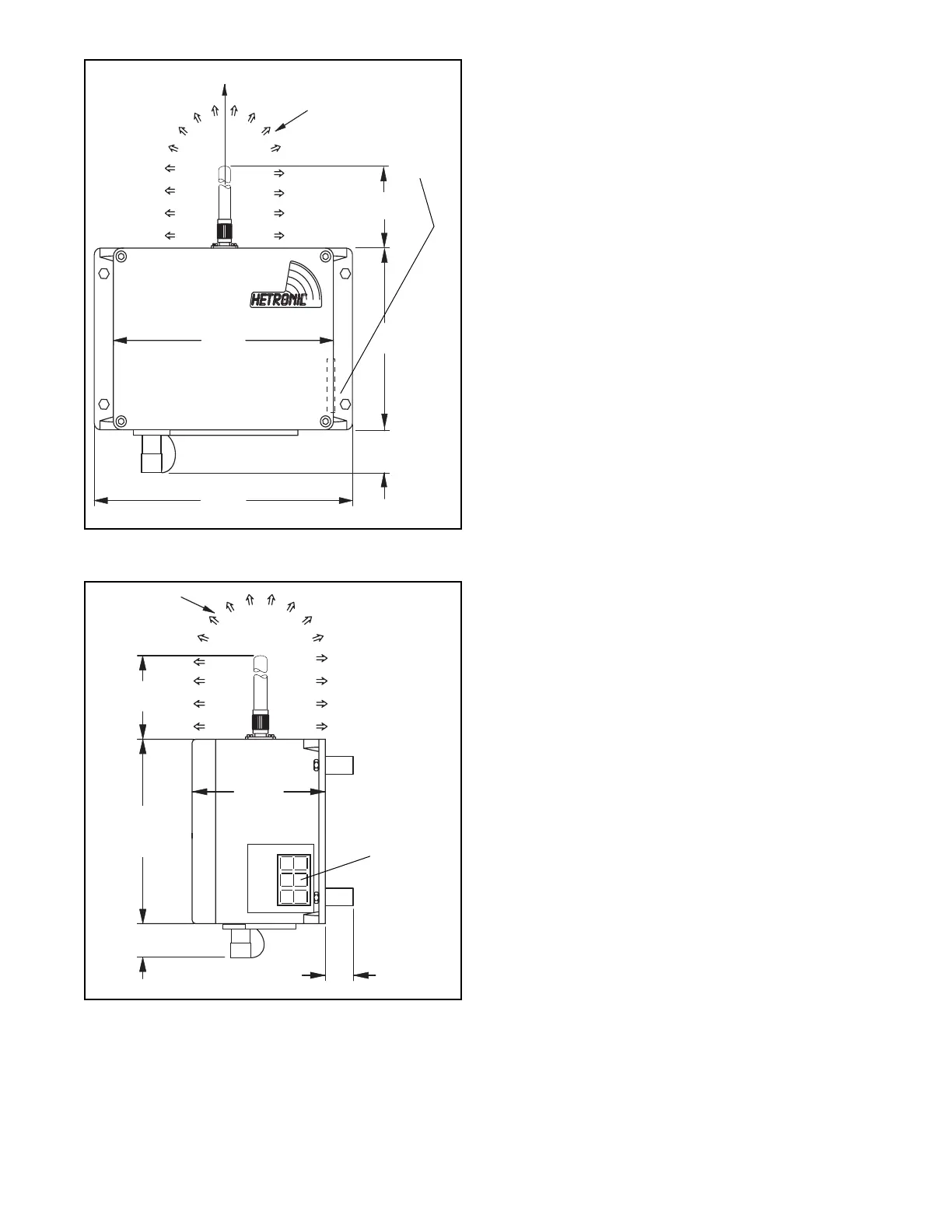

Be sure that the Diagnostic Display panel is clearly

visible.

The receiver wiring is critical for proper system

operation. Make all connections with good quality

contacts or solder joints to ensure proper electrical

contact.

Supply voltage and ground wiring are crucial and must

be connected to reliable connecting circuitry. Do not

use a chassis ground for this equipment. The ground

wire must be connected directly to the vehicle battery

negative post.

IMPORTANT: Power supply wiring must be at least

AWG 12 to prevent power drop.

The output control signals to the proportional control

valves should be routed separately from any wiring that

could produce transient voltage interference.

Interference or "induced voltage spikes" could cause

erratic performance of the proportional controls.

Mount the Actuators (Optional)

Mount and attach the actuators to the hydraulic valves

or to the mechanical linkage with the brackets supplied.

Attach Wiring Harness (Optional)

Plug the wiring harness into the receiver and into the

corresponding actuators.

Connect Electrical Wiring

Connect all remaining wires (power supply, engine

start-stop, etc.) according to the wiring diagram of the

crane/machine and the radio remote control.

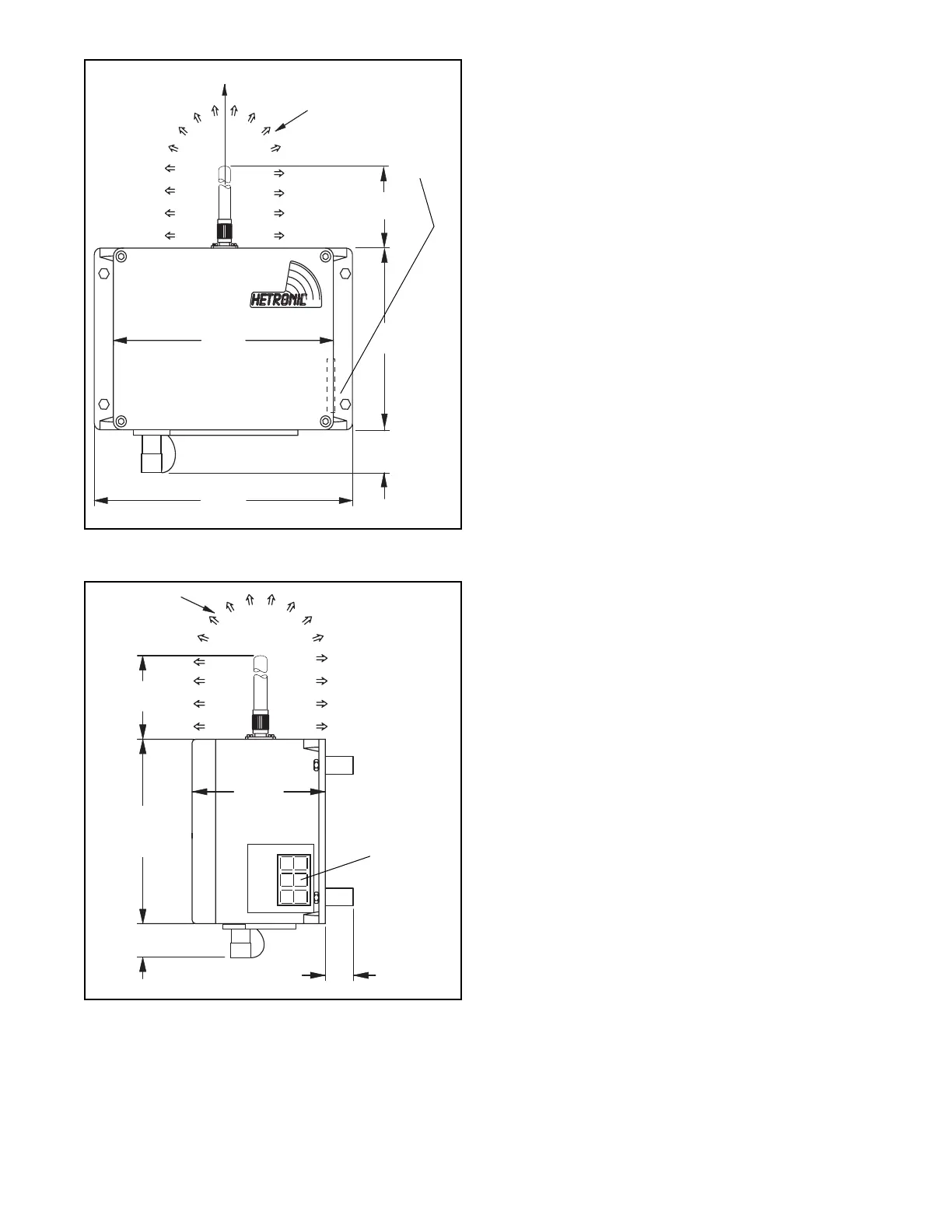

8.29"

(210.5 mm)

9.72"

(246.8 mm)

6.40"

(160.0 mm)

1.00"

(25.0 mm)

4.25"

(106.3 mm)

Antenna must

be vertical

(pointing up).

Area must be

free of

obstructions

Diagnostic

Display Panel

4.25"

(106.3 mm)

6.38"

(162 mm)

4.47"

(113.5 mm)

1.00"

(25.0 mm)

1.00"

(25.0 mm)

Area must

be free of

obstructions

Do not block

visibility of

diagnostic

panel.

Loading...

Loading...